A beer canning production line

A production line and beer technology, applied in the field of beer production, can solve the problems of splashing on the bottle, falling, and low alcohol content, and achieve the effect of improving the degree of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

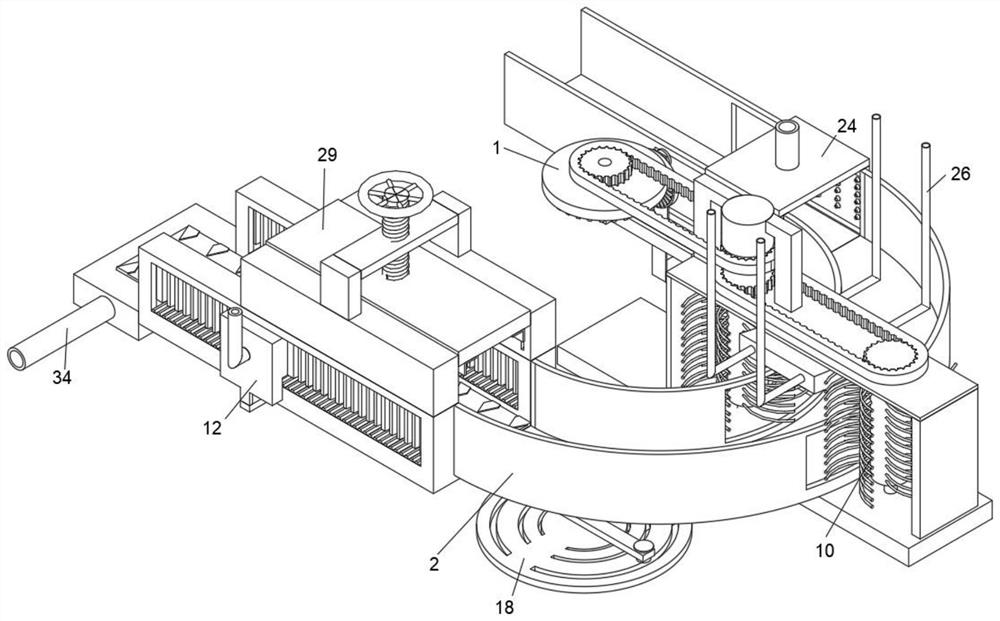

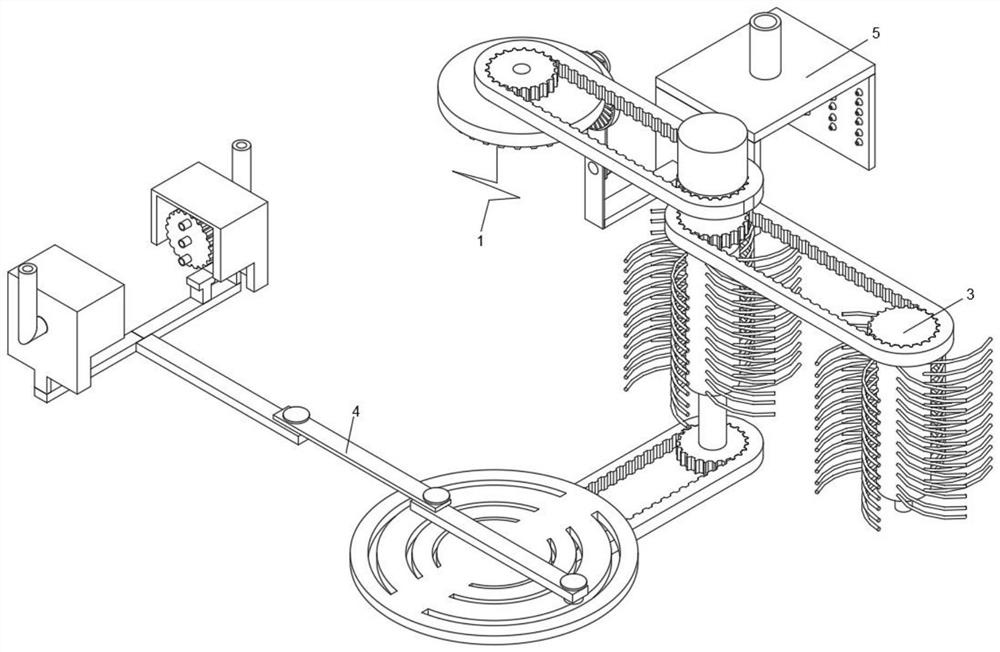

[0030] see Figure 1-2 , an embodiment provided by the present invention: a beer canning production line, including a support transmission mechanism 2, a transmission mechanism 1 is fixedly installed inside the support transmission mechanism 2, and the transmission mechanism 1 includes a scrubbing device 3, an intermittent moving device 4 and The cleaning device 5 is geared to the bottom of the side end of the scrubbing device 3 , and the intermittent moving device 4 is fixedly connected to the bottom end of the scrubbing device 3 .

[0031] like image 3 , the scrubbing device 3 includes a first bevel gear 6, a first transmission belt 7, an output motor 8, a second transmission belt 9 and a rotating contact rod 10, the first transmission belt 7 is fixedly connected to the bottom end of the output motor 8, and the first bevel gear 6 is fixedly connected to the bottom of one end of the first transmission belt 7 away from the output motor 8, the second transmission belt 9 is fi...

Embodiment 2

[0039] On the basis of Example 1, as Figure 8 As shown, the discharge chute frame 25 also includes a rotating contact wheel 36 and a contact sponge pad 37, the rotating contact wheel 36 is symmetrically connected to the interior of the discharge chute frame 25, and the contact sponge pad 37 is fixedly connected to the rotating contact wheel 36 at equal distances. .

[0040] During the implementation of this embodiment, the contact wheel 36 is rotated and connected to the inside of the discharge chute frame 25, and the contact sponge pad 37 is fixedly connected to the outer ring of the rotating contact wheel 36 at equal distances. When moving forward, it can come into contact with the contact sponge pad 37, and the unblown bottle body can be cleaned again by contacting the sponge pad 37, and when the bottle body is in contact with the contact sponge pad 37, it can drive the rotating contact wheel 36 to rotate , which is convenient for cleaning the bottle body again.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com