High-precision wind power brake machining process

A processing technology and brake technology, applied in the field of high-precision wind power brake processing technology, can solve the problems of low production and processing efficiency, low processing accuracy, large processing errors, etc., and achieve improved production efficiency, simplified processing steps, and processing accuracy grades. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A high-precision wind power brake processing technology, comprising the following steps:

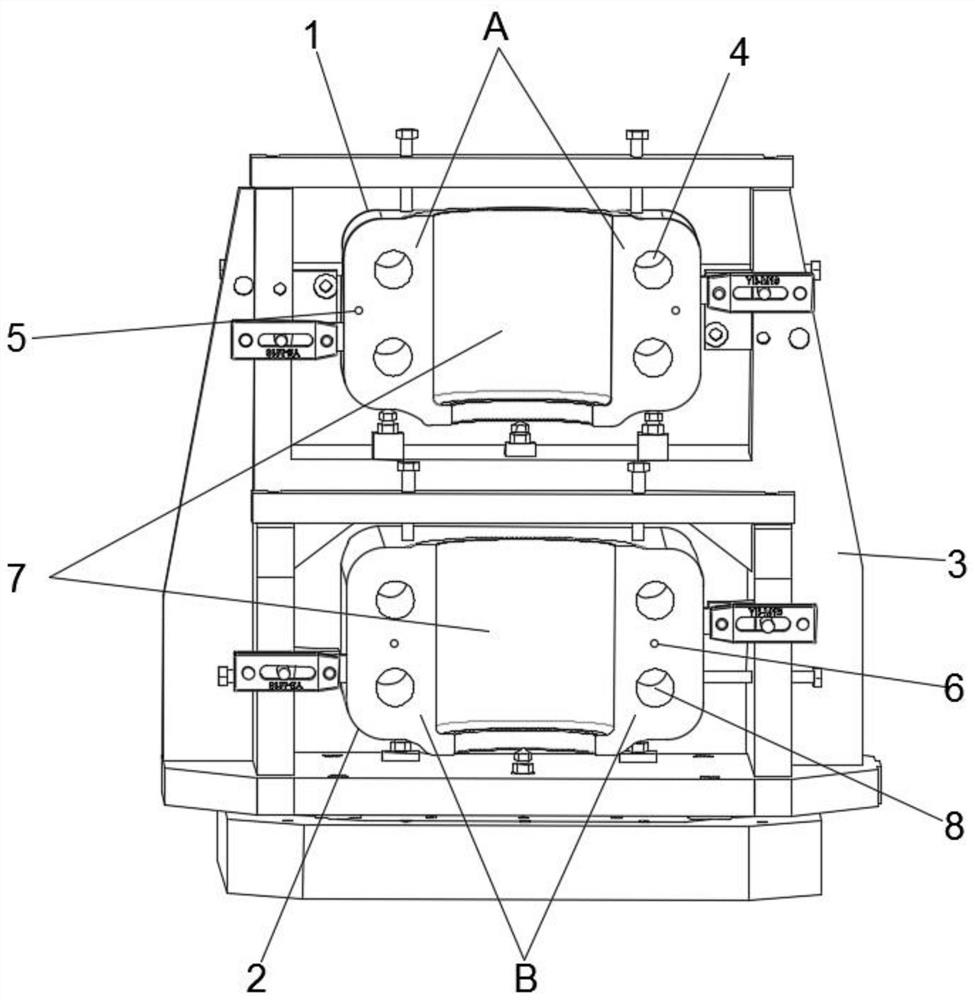

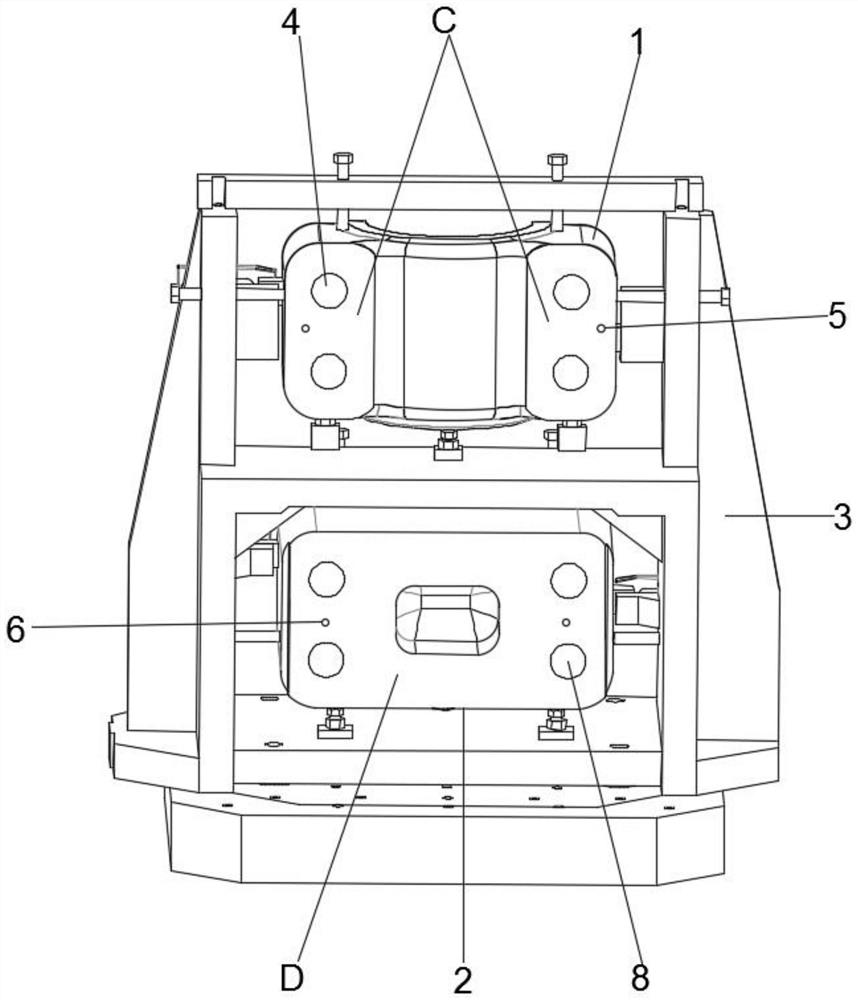

[0029] S1. Machining datum plane: place the upper base 1 and the lower base 2 on the first fixture 3, clamp the left and right sides of the upper base 1 and the lower base 2, make the combined hole 7 upward, and use the horizontal machining center to roughly machine the A surface , B surface, C surface, D surface, the first positioning hole 4, the second positioning hole 8, the first threaded lifting hole 5 and the second threaded lifting hole 6, the model of the horizontal machining center is MDH-80, the first Both the positioning hole 4 and the second positioning hole 8 are Φ51.1H8 through holes, the depth of the first positioning hole 4 is 20mm, and the depth of the second positioning hole 8 is 40mm;

[0030] Specifically, the upper seat 1 and the lower seat 2 are simultaneously clamped and positioned by the first fixture 3, the number of clampings is reduced, and machining err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com