Stainless steel pipe fitting welding machine

A technology for welding and processing machinery for pipe fittings, applied in the field of welding and processing machinery for stainless steel pipe fittings, which can solve the problems of easy butt joint deviation of stainless steel pipes and insufficient clamping force of stainless steel pipes, so as to improve stability, improve butt tightness, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the technical scheme in the embodiment of the present invention will be clearly described, and it is understood, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments; Embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in all other embodiments obtained without making creative labor.

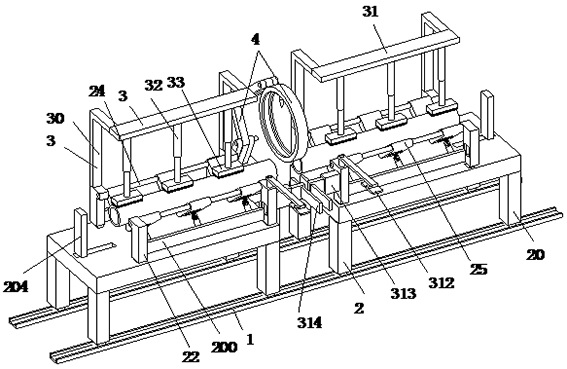

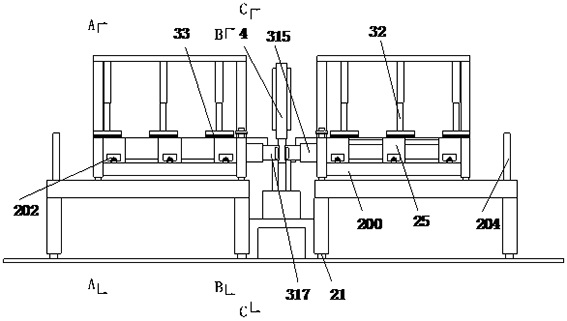

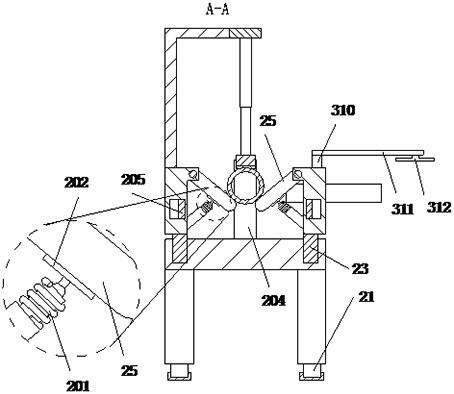

[0028] See figure 1 with figure 2 A stainless steel pipe welding machine, comprising a rail, a clamping mechanism 2, pressing mechanism 3 and the welding machine 4, the longitudinal track 1 mounted symmetrically on the ground, between the left and right upper rails 1 are mounted symmetrically clamping means 2, an upper clamping mechanism 2 is provided with pressing means 3, is mounted on the welding machine on the floor 4, the welding machine 4 is located between the clamping mechanism 2 and the welding machine 4 is located at the rear side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap