CCD positioning full-automatic sheet machine

A sheet machine, fully automatic technology, applied in the direction of climate sustainability, final product manufacturing, metal processing, etc., can solve the problems of inconvenient sheet processing of different sizes, low sheet transport efficiency, inconvenient control of local drives, etc. , to achieve the effect of accurately fixing the position and improving the discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

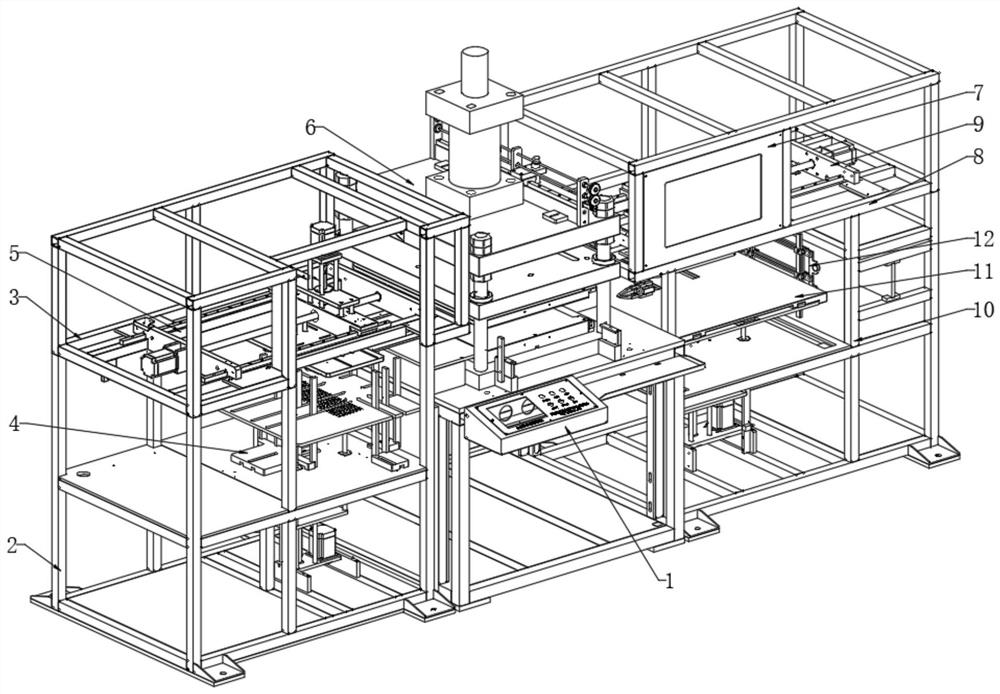

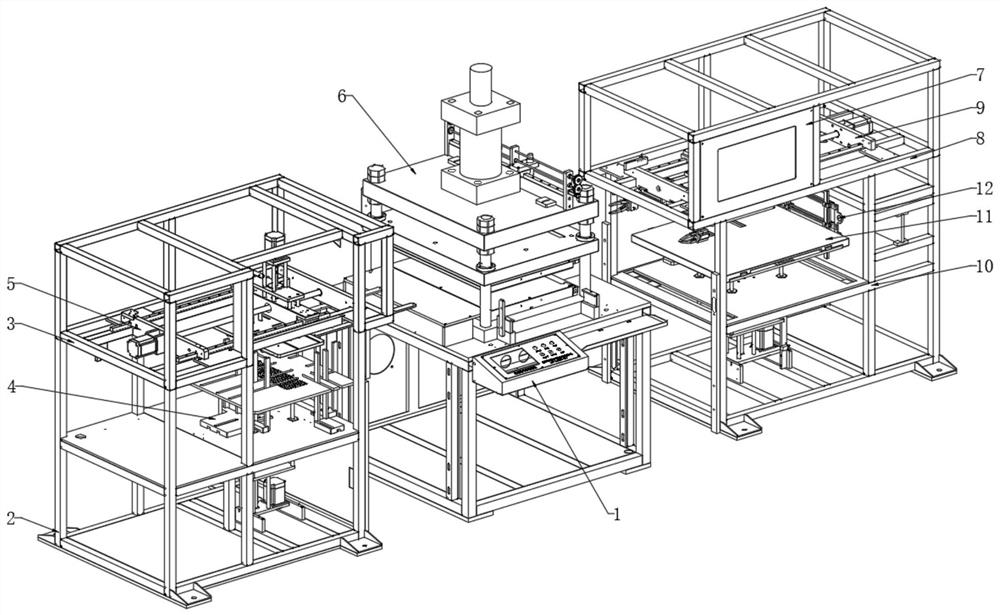

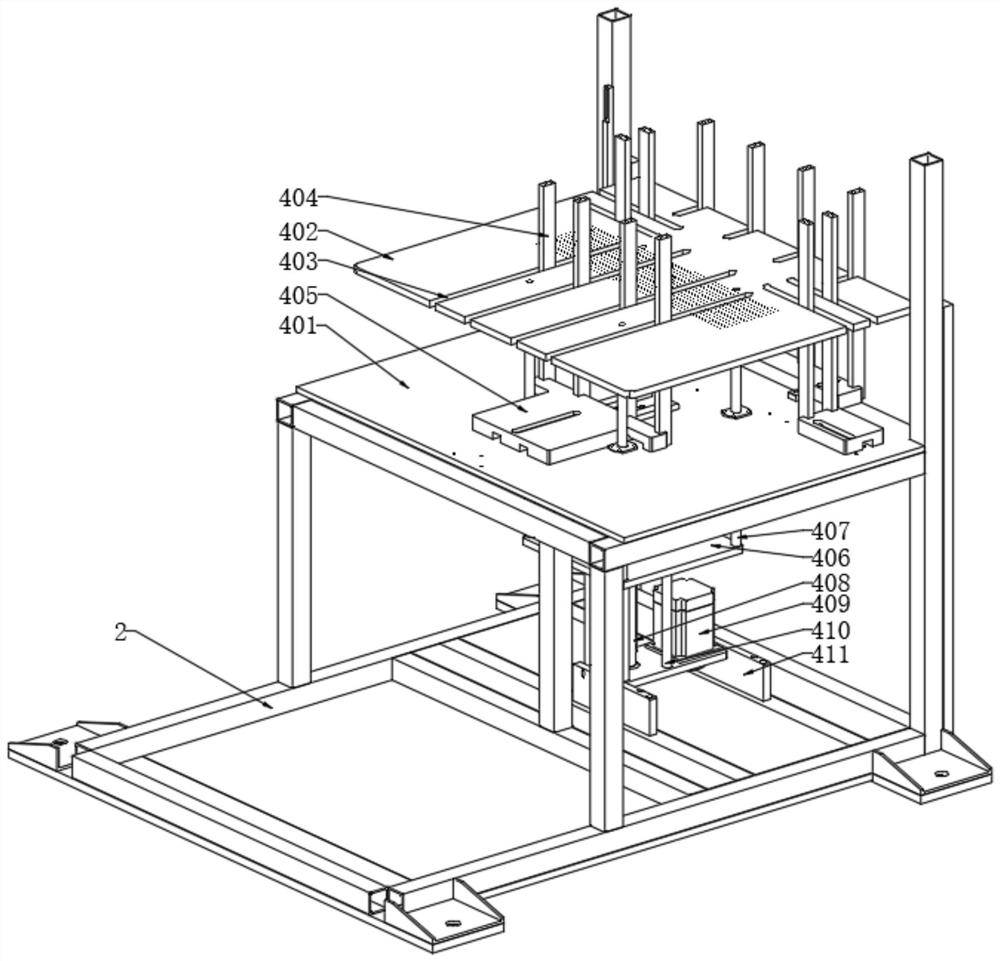

[0049] see Figure 1-21 , a CCD positioning fully automatic sheet machine, comprising a workbench 1, the top of the workbench 1 is fixedly connected with a sheet material processing device 6 for sheet material processing, one side of the workbench 1 is provided with a fixed frame-2, the fixed frame A feeding platform 4 for material lifting is arranged inside a 2, and a fixing frame 3 10 is arranged on the other side of the workbench 1, and a receiving platform 11 for stacking finished materials and a stacking platform 11 for finished materials are arranged inside the fixing frame 10. Pushing device 12, the top of fixed frame one 2 is fixedly connected with fixed frame two 3, and the feeding mechanism 5 of material conveying is arranged in fixed frame two 3, and the top of fixed frame three 10 is fixedly connected with fixed frame four 8, and fixed frame A receiving device 9 for finished material transportation and unloading is arranged in the fourth 8, and a control panel 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com