Efficient triangular bag making device

A bag-making device and a technology for triangular bags, which are applied in the field of high-efficiency bag-making devices for triangular bags, can solve the problems of low preparation efficiency and high material waste rate of triangular bags, and achieve the effects of simple structure, improved production efficiency and low loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

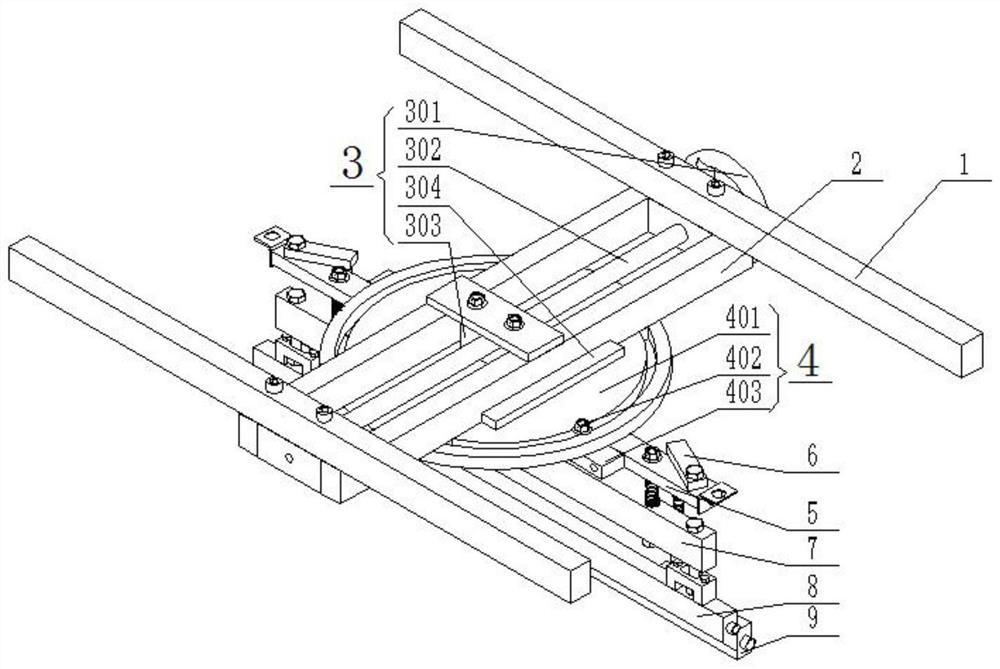

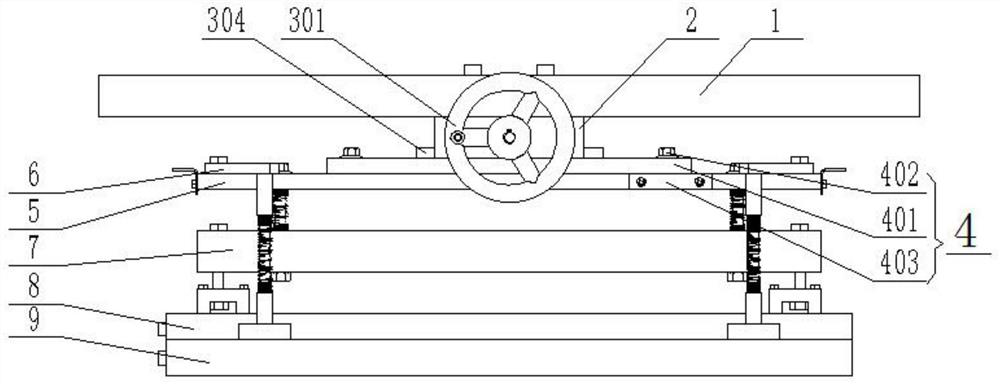

[0024] like figure 1 As shown, a high-efficiency bag-making device for triangular bags includes a mounting frame 2, a cutter displacement device 3, a cutter angle adjustment device 4, a mounting rod 5, a heating rod mounting block 6, a cutter mounting rod 7, a cutter 8 and Heating rod 9, the two ends of the installation frame 2 are connected to the frame cross bar 1 by bolts, the cutter displacement device 3 is arranged inside the installation frame 2, and the cutter angle adjustment device 4 is arranged on The lower side of the installation frame 2, and the cutter displacement device 3 is connected to the cutter angle adjustment device 4 by bolts, and the installation rod 5 is connected to the cutter angle adjustment device 4 by bolts. One end of each heating rod installation block 6 is connected to the two ends of the installation rod 5 by bolts, and the two ends of the heating rod 9 are connected to the other ends of the two heating rod installation blocks 6 by bolts, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap