Double-mechanical-arm digital ray detection device and automatic detection method

A digital ray and detection device technology, which is applied in measuring devices, material analysis using radiation, material analysis using wave/particle radiation, etc., can solve the problems of difficult control of motion mechanisms and inability to realize automatic detection, etc., and achieve motion control Easy to implement, realize automatic detection, improve imaging quality and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

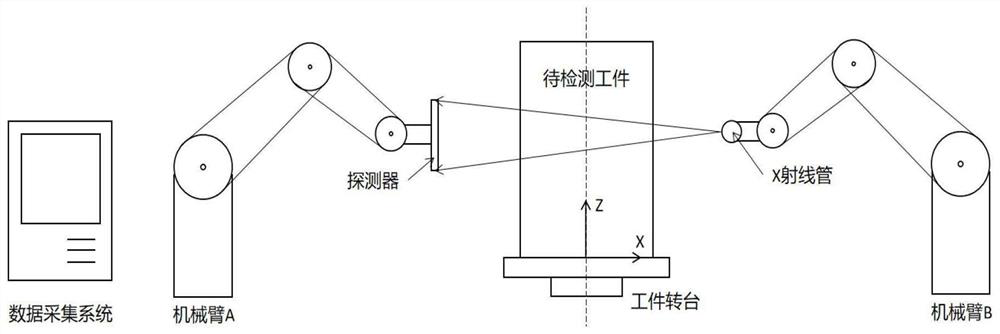

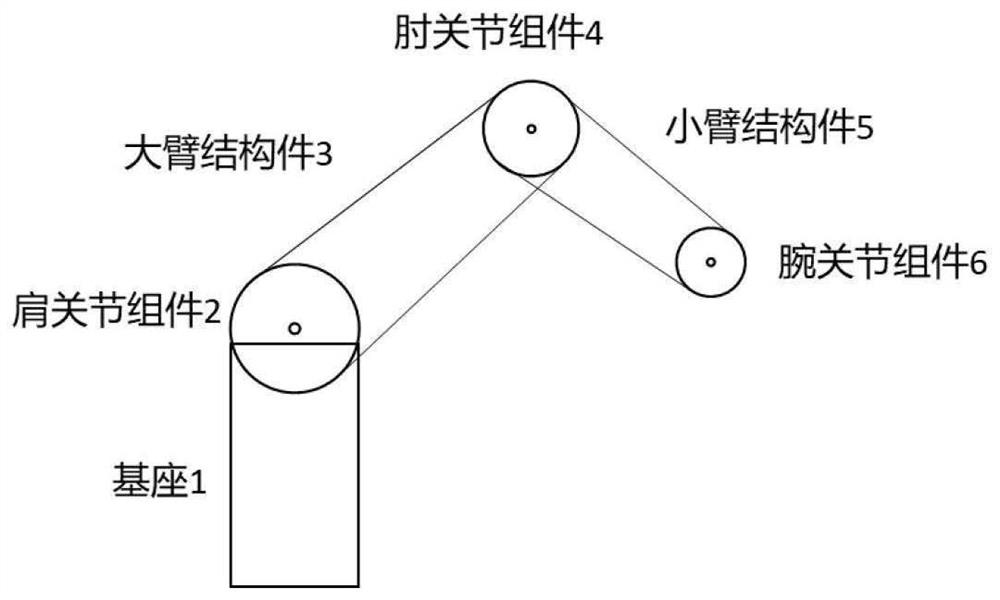

[0056] A specific embodiment of the present invention discloses a dual-manipulator digital radiation detection device,

[0057] The device includes a ray source, a detector, a workpiece turntable, a first mechanical arm, a second mechanical arm, a control system and a data acquisition system;

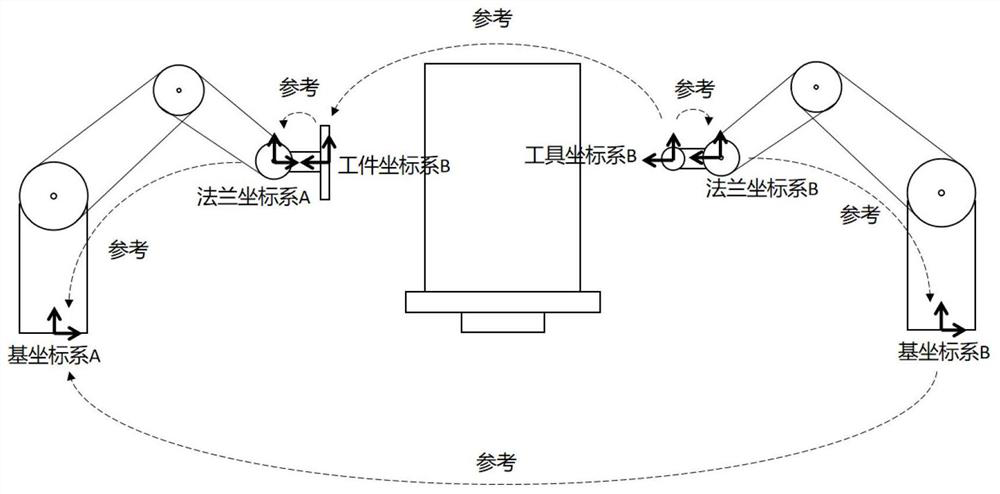

[0058] The first mechanical arm and the second mechanical arm are placed on opposite sides of the workpiece turntable, and the radiation source and detector are installed on the first mechanical arm and the second mechanical arm respectively; the workpiece to be measured is installed on the workpiece turntable; the data acquisition system is used To collect detector imaging data;

[0059] The control system changes the position and direction of the detector and the ray source by adjusting the movement axes of the first mechanical arm and the second mechanical arm, so as to realize the detection of the workpiece; the central beam of the ray source is always perpendicular to the surface o...

Embodiment 2

[0095] Another embodiment of the present invention provides an automatic detection method based on a double-manipulator digital radiation detection device, including the following steps:

[0096] S1. The control system runs the robotic arm control program;

[0097] S2. The control system controls the ray source and the detector to move to the i-th scanning path point, and the initial value of i is 1;

[0098] S3. The control system outputs an instruction to start collecting signals to the data acquisition system, then executes the input waiting instruction, and waits for the data acquisition system to complete data acquisition;

[0099] S4. After the data acquisition system receives the instruction to start collecting signals, it turns on the ray source and the detector, and collects the data output by the detectors, and outputs a collection completion signal to the control system after the collection is completed;

[0100] S5. After the control system receives the collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com