CELL-based edge defect detection method

A detection method and edge defect technology, which is applied in the field of CELL-based edge defect detection, can solve problems such as difficulty in robustness, achieve high detection accuracy and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

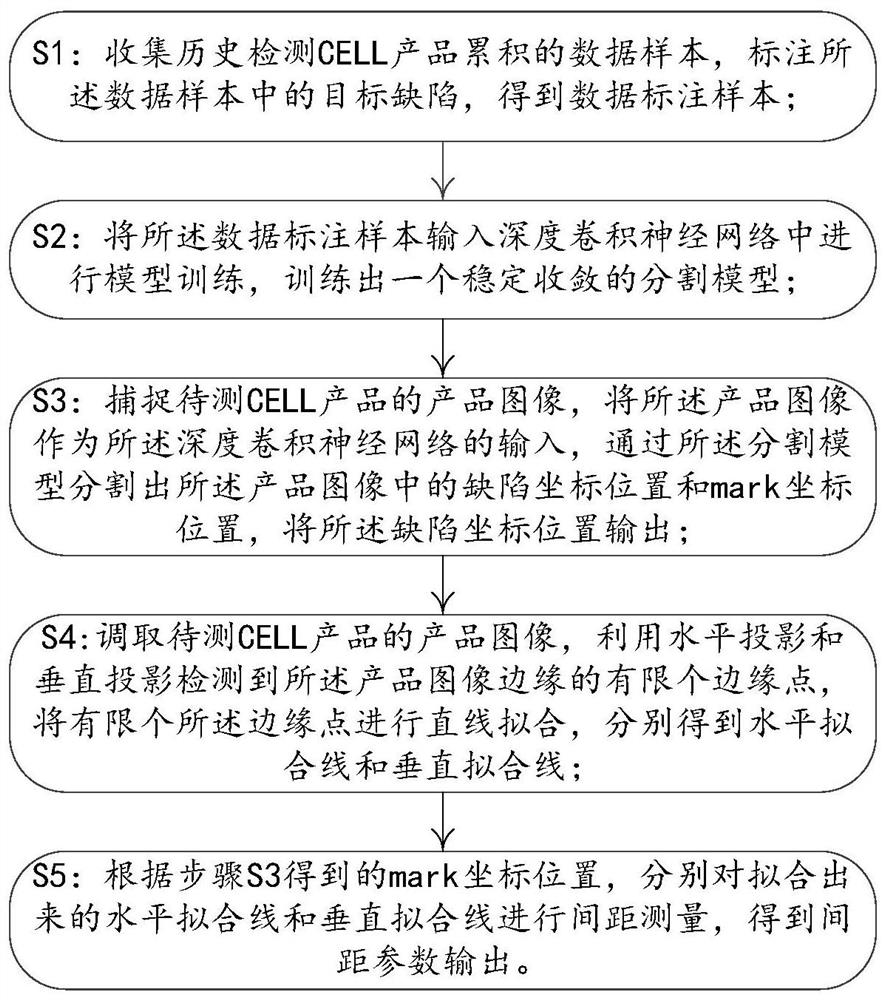

[0035] like figure 1 , The core of the invention is to provide a method for detecting a defect on the edge of the CELL, the detection method comprising the steps of:

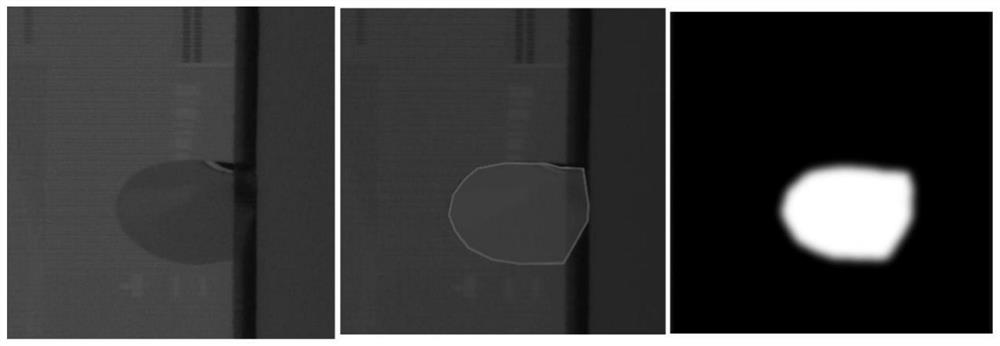

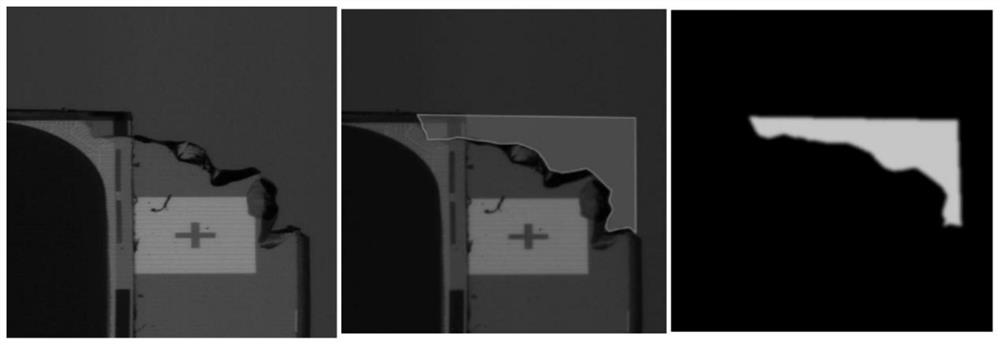

[0036] Collecting historical test CELL product accumulation data samples are denoted by the target defective data samples to obtain a sample label data; label is a need to use target segmentation model into the defect and data representation is denoted by the fixed objects are the types of defects and product surface logo mark printed pattern; certain defects include: surface defects, and a corner mark defect margins defects, wherein surface defects and defect margin mark marked contours are used, a packed marked corner defect; as figure 2 , The dirty spots on the surface defects of the contour labeled; if image 3 , The corners of the defective filling does labeling according to image 3 For the deletion of the defect at the corners, the use of the complete filling manner, the defect label.

[0037] The annotation da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com