Mounting device for motor assembly

A technology for installing equipment and pressing molds, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem that the end cover is not easy to fit on the rotating shaft, and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

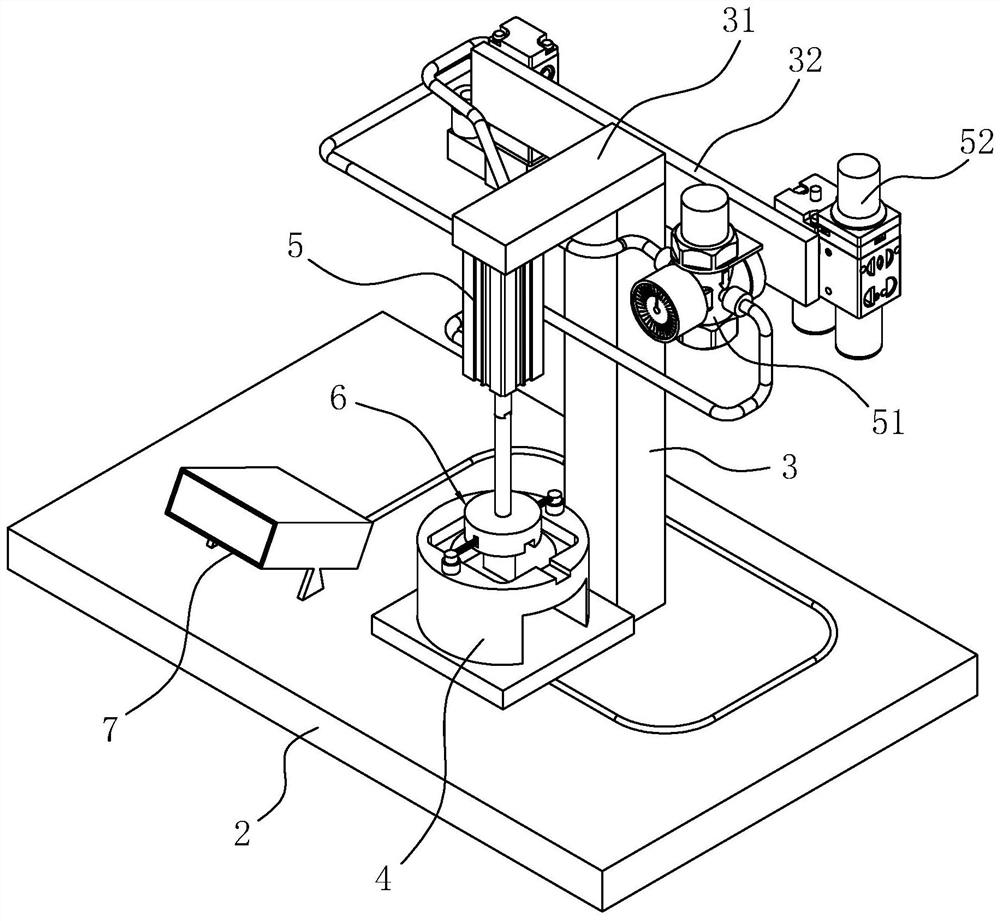

[0038] The following is attached Figure 1-8 The application is described in further detail.

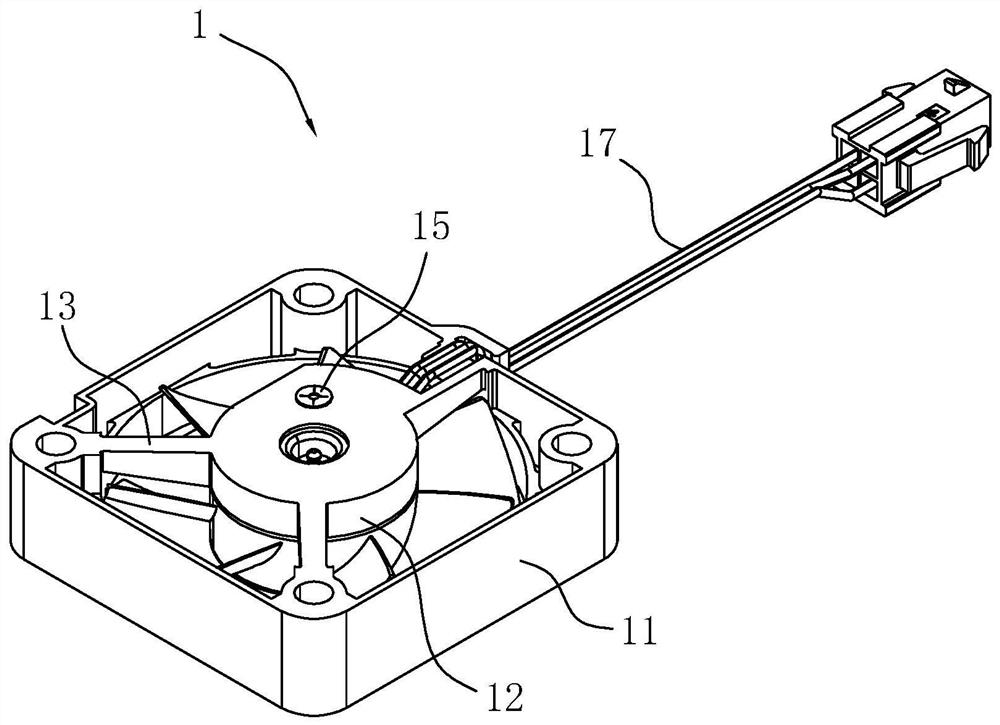

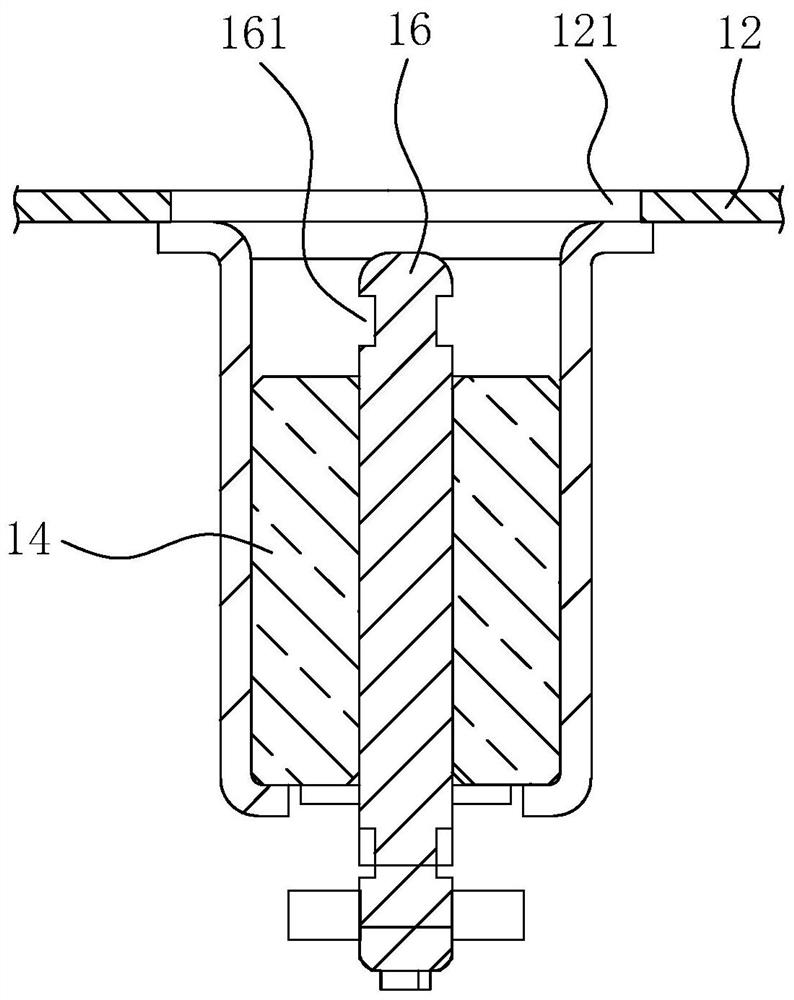

[0039] The embodiment of the present application discloses an installation device for motor assembly. refer to image 3 , the installation equipment for motor assembly includes a base 2 and a bracket 3, a mold base 4 is fixed on the base 2, a die 6 is installed on the support 3 above the die base 4 and the power to drive the die 6 to move close to or away from the die base 4 Part 5, a pressure sensor is installed at the bottom of the mold base 4, and a display 7 is connected to the stress sensor. Place the micro motor 1 on the mold base 4, place the end cap 15 on the installation port 121 of the inner casing 12, then start the power part 5 to drive the die 6 to move to the die base 4, and the die 6 applies the end cap 15 The pressure causes the end cap 15 to be sleeved on the rotating shaft 16, and the value measured by the pressure sensor can be displayed on the display 7 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com