Automatic waxing system for pots

An automatic, pot-like technology, used in metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of complicated wax adding devices, spraying to other places, and difficulty of wax adhering to polishing wheels. , to achieve the effect of saving material cost, saving floor space and saving labor and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

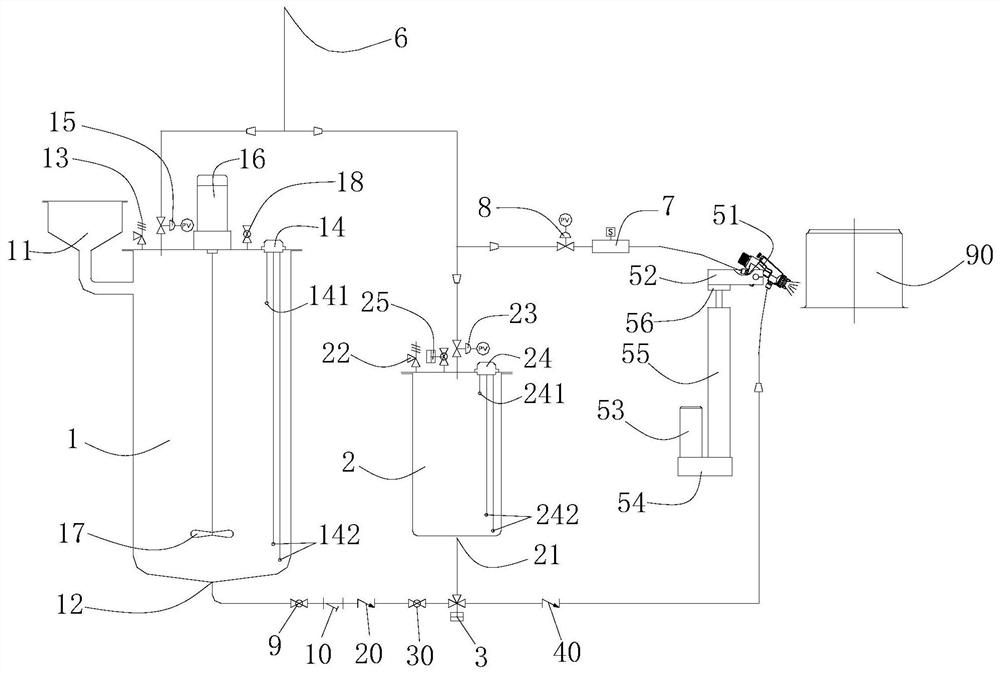

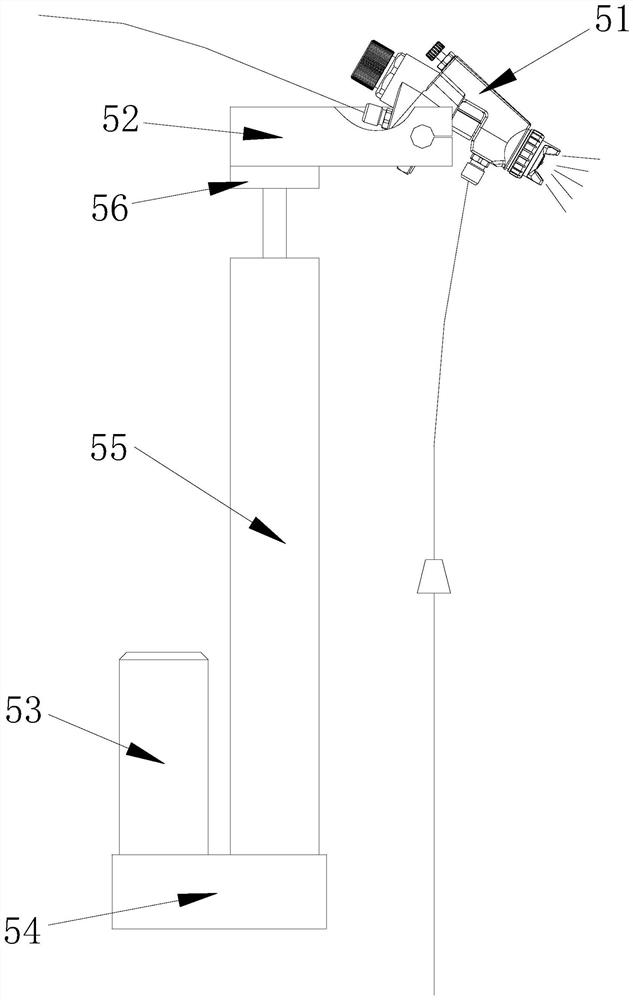

[0024] refer to figure 1 and figure 2, is an automatic waxing system for pots, including a control system and a wax storage tank 1 controlled by the control system, a pressure device, a waxing device, and an external air source 6; the wax storage tank 1 stores paste polishing wax, and the pressure The device is respectively connected with the wax storage tank 1 and the waxing device, and transports the paste polishing wax from the wax storage tank 1 to the waxing device; the external air source 6 is respectively connected with the wax storage tank 1 and the waxing device; the waxing device Align the pan product 90 to be polished.

[0025] This device uses high-concentration paste polishing wax instead of water wax or solid wax to improve the polishing effect. Through the pressure device and waxing device, the paste polishing wax is directly sprayed on the product to avoid the high-speed rotating polishing wheel from flying the wax. Go, to avoid the problem of uneven sprayin...

Embodiment 2

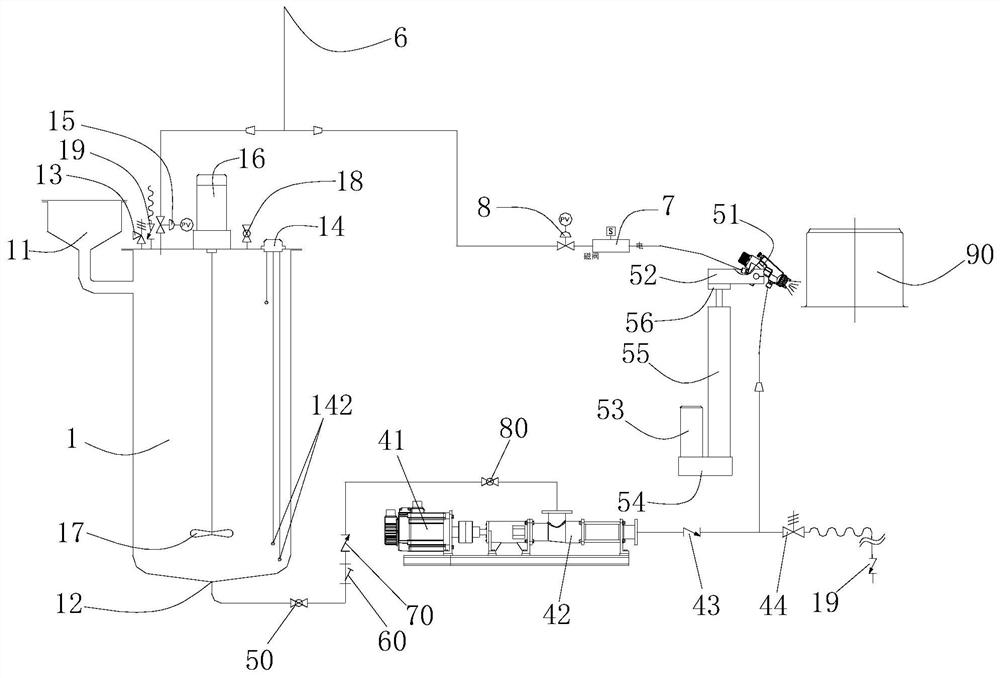

[0032] refer to image 3 , is another automatic waxing system for pots. The difference between Embodiment 2 and Embodiment 1 is that the pressure device is a screw pump 4, and the screw pump 4 includes a screw pump body 41, which is controlled by a PLC controller and used to control the screw pump. The first servo motor 42, the third one-way valve 43, and the back pressure valve 44 of the pump body 41; the inlet of the screw pump body 41 is connected to the first wax outlet 12 of the wax storage tank 1 through pipelines; the first wax outlet 12 is connected to the The pipeline between the inlets of the screw pump body 41 is sequentially connected with the fourth manual ball valve 50, the second filter valve 60, the fourth one-way valve 70, and the fifth manual ball valve 80, and the outlet of the fourth one-way valve 70 points to the screw pump body 41 inlet; the outlet of the screw pump body 41 is connected with the waxing device through the third one-way valve 43, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com