Mounting and fixing method for structural pulling seam in aluminum alloy formwork supporting system

An aluminum alloy formwork and support system technology, which is applied to formwork/formwork members, formwork/formwork/work frame connectors, formwork/formwork/work frame, etc., can solve problems such as increased cost and cumbersomeness, and achieve The effect of avoiding offset, strengthening stability, strengthening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

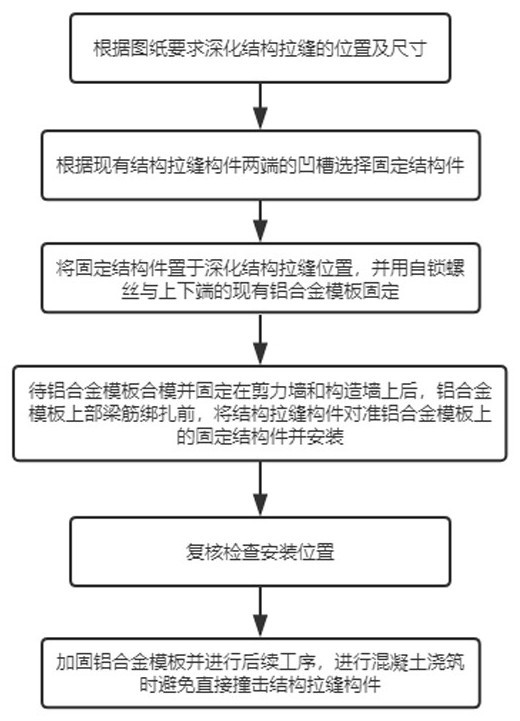

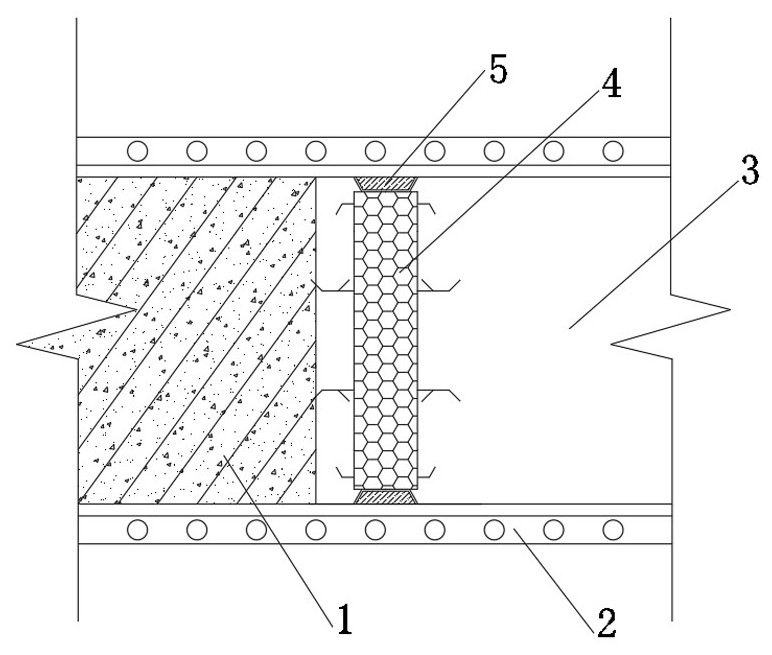

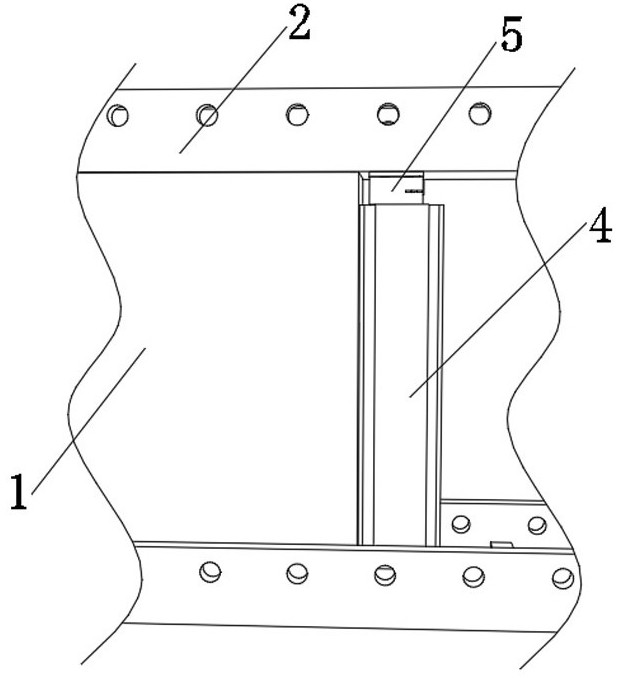

[0046] A method for installing and fixing structural drawing seams in an aluminum alloy formwork support system, such as Figure 1-3 shown, including the following steps:

[0047] S1: Deepen the position and size of the structural seams according to the requirements of the drawings;

[0048] S2: Select the fixed structural member 5 according to the grooves at both ends of the seam member 4 in the existing structure;

[0049] S3: Place the fixed structural part 5 at the position of the deepening structure, and fix it with the existing aluminum alloy formwork 2 at the upper and lower ends with self-locking screws;

[0050] S4: After the aluminum alloy formwork 2 is clamped and fixed on the shear wall 1 and the structural wall 3, before the upper beam reinforcement of the aluminum alloy formwork 2 is bound, the structural drawing joint member 4 is aligned with the fixed structural member on the aluminum alloy formwork 2 5 and install;

[0051] S5: Review and check the installa...

Embodiment 2

[0056] A method for installing and fixing structural drawing seams in the aluminum alloy formwork support system described in Embodiment 1, such as Figure 2-7 As shown, when plugging the structural seam member 4, the following steps are included:

[0057] S51: After aligning the structural seam member 4 with the fixed structural member 5 and connecting it, the bottom end of the elastic filling block 12 is squeezed into the groove on the structural seam member 4;

[0058] S52: Both sides of the elastic support 27 at the bottom of the elastic filling block 12 are squeezed to shrink in the middle, and the connecting arm 25 is pushed upward to push the telescopic assembly 24 to shrink, and the groove on the structural seam member 4 is tightly sealed.

[0059] In order to facilitate the sealing of the grooves on the structural joint member 4; it also includes a shear wall 1 and a structural wall 3 arranged between two aluminum alloy formworks 2, and two groups set on the outer wal...

Embodiment 3

[0062] A method for installing and fixing structural drawing seams in the aluminum alloy formwork support system described in Embodiment 1, such as Figure 4-6 As shown, in order to facilitate the adjustment of the distance between the elastic filling block 12 and the elastic filling block 12; this embodiment makes the following improvements on the basis of embodiment 2: the bottom outer wall of the fixed structure 5 is provided with an inverted convex structure groove , the inner wall of the inverted convex structure groove is slidably connected with the convex seat 7 with the same number as the elastic filling block 12, the top outer wall of the convex seat 7 is provided with a connecting groove 23, and the inner wall of the connecting groove 23 is placed with a connecting threaded sleeve 20, connected The threaded sleeve 20 is composed of an upper threaded plate and a lower threaded plate. A square groove 21 is provided on one side of the outer wall connecting the threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com