Ejecting evaporative cooling type air-cooled heat pump unit

An air-cooled heat pump and cooling technology, applied in refrigerators, compressors, mechanical equipment, etc., can solve the problems of high energy consumption, large volume and high manufacturing cost of evaporative cooling and heat pump units, and achieve better cooling effect and reduce The volume of the unit, the effect of reducing the flying water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

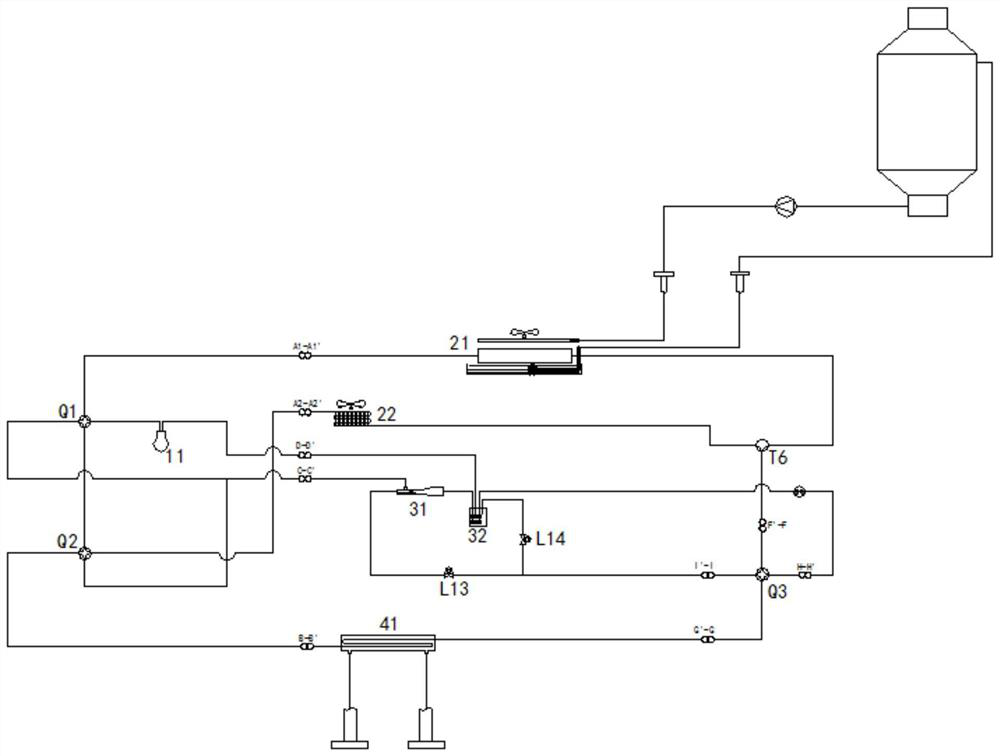

[0096] Such as Figure 16 Shown: Air-cooled ejector cooling mode:

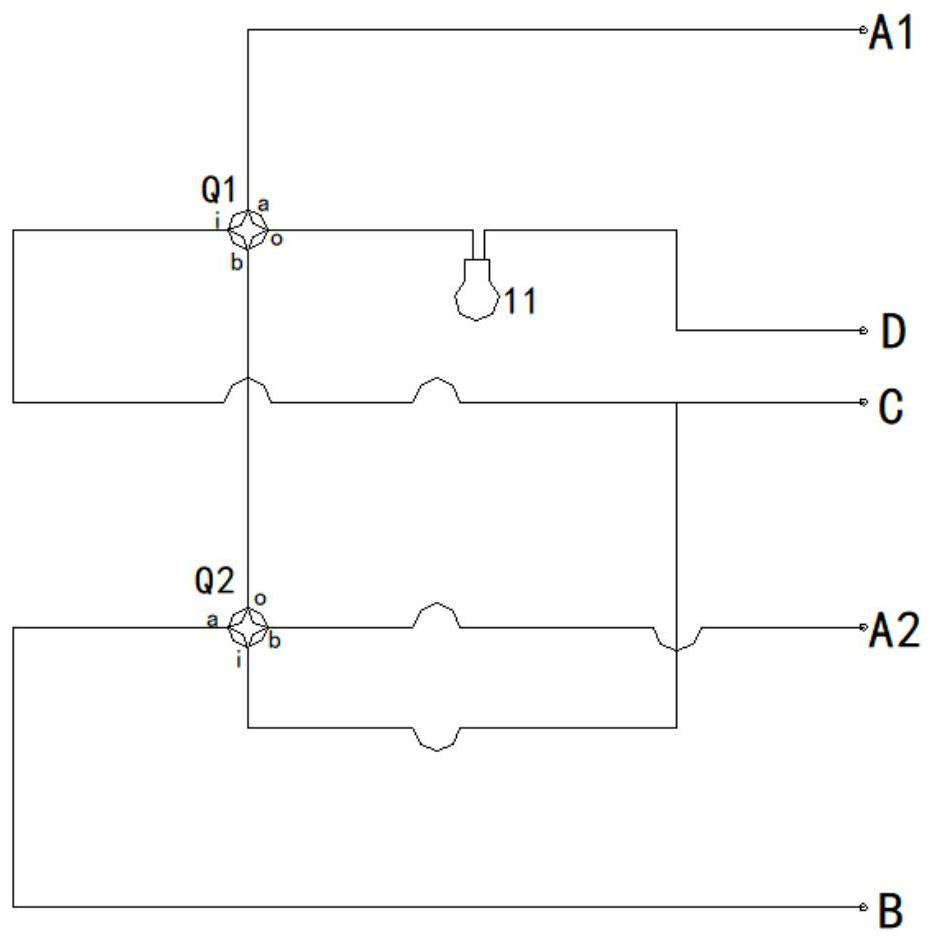

[0097] Refrigerant circulation system: the first four-way valve Q1ob and ai terminals are connected; the second four-way valve Q2ob and ai are connected; the sixth three-way valve T6ao is connected; the third four-way valve Q3oa and bi are connected; The fourteenth two-way valve L14 is closed; the thirteenth two-way valve L13 is opened.

[0098] In the high-pressure refrigerant circuit of the refrigerant cycle, the refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the fourth valve port b of the first four-way valve Q1, and the first valve port o of the second four-way valve Q2. and the fourth valve port b, the air source heat exchanger 22, the second valve port a and the first valve port o of the sixth three-way valve T6 of the rectification module, the first valve port o and the first valve port o of the third four-way valve Q3 Three valve ports a, the thirt...

Embodiment 2

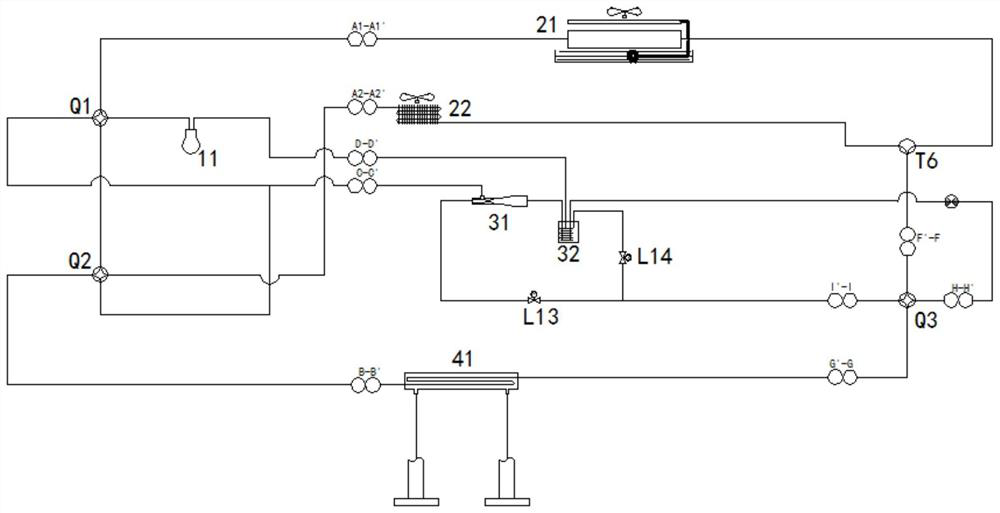

[0113] refer to Figure 19 , air source heat pump conventional heating mode:

[0114] Refrigerant circulation system: the first four-way valve Q1ob and ai are connected; the second four-way valve Q2oa and bi are connected; the third four-way valve Q3ia and bo are connected; the sixth three-way valve T6ao is connected; The thirteenth two-way valve L13 is closed, and the fourteenth two-way valve L14 is opened.

[0115] Refrigerant circulation path: The refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the fourth valve port b of the first four-way valve Q1, the first valve port o and the third valve of the second four-way valve Q2 port a, indoor heat exchanger 41, the second valve port i and third valve port a of the third four-way valve Q3 of the rectification module, the fourteenth two-way valve L14 of the injection module, and the gas-liquid separator 32 The second inlet of the refrigerant, the gaseous refrigerant through the...

Embodiment 3

[0122] refer to Figure 20 , air-cooled heat pump injection heating mode:

[0123] Refrigerant circulation system: the first four-way valve Q1ob and ai are connected; the second four-way valve Q2oa and bi are connected; the third four-way valve Q3ia and bo are connected; the sixth three-way valve T6ao is connected; The thirteenth two-way valve L13 is opened, and the fourteenth two-way valve L14 is closed.

[0124] In the high-pressure refrigerant circuit of the refrigerant cycle, the refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the fourth valve port b of the first four-way valve Q1, and the first valve port o and the second three-way valve Q1. The third valve port a, the indoor heat exchanger 41, the second valve port i and the third valve port a of the third four-way valve Q3 of the rectification module, the thirteenth two-way valve L13 of the injection module, and the injector 31 air inlet, injection port, the first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com