Integrated high-frequency magnetic element

A magnetic component, integrated technology, applied in electrical components, transformer/inductor components, transformers, etc., can solve the problems of large floor space and difficult welding of magnetic components, saving welding area, compact structure, The effect of reducing the difficulty of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

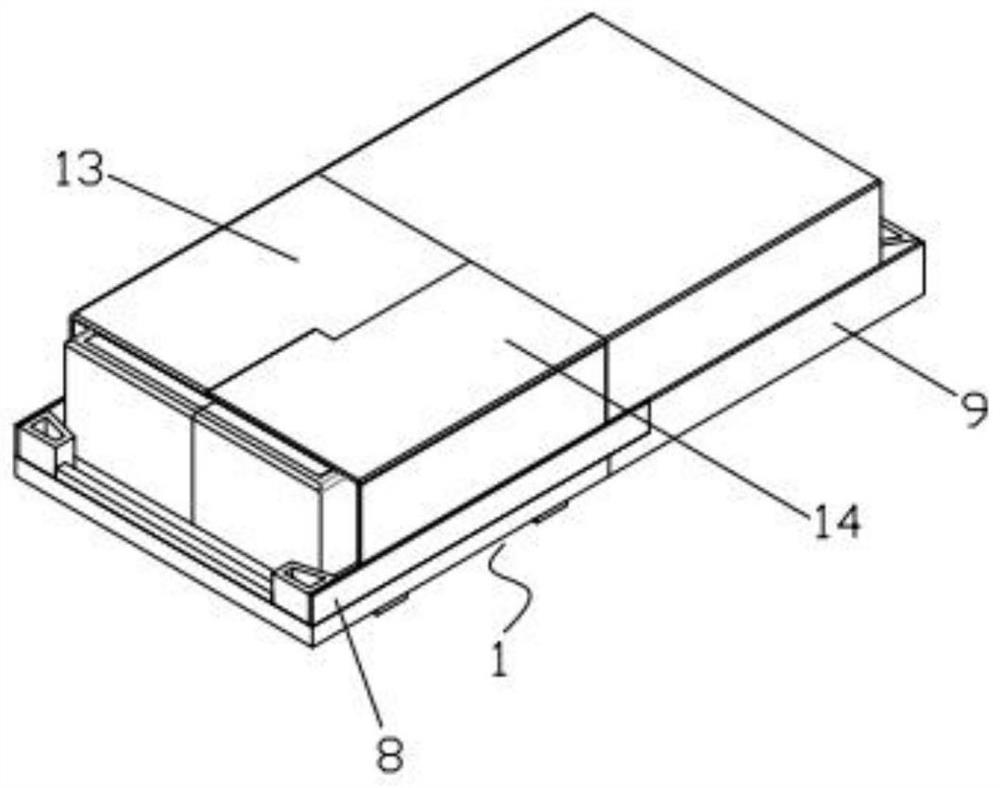

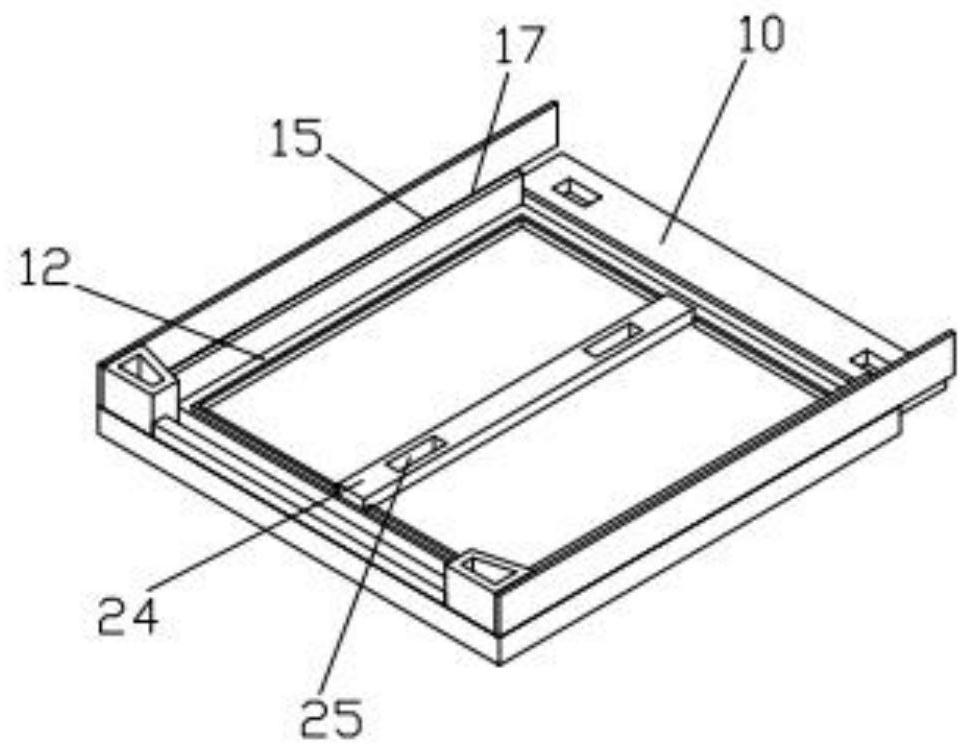

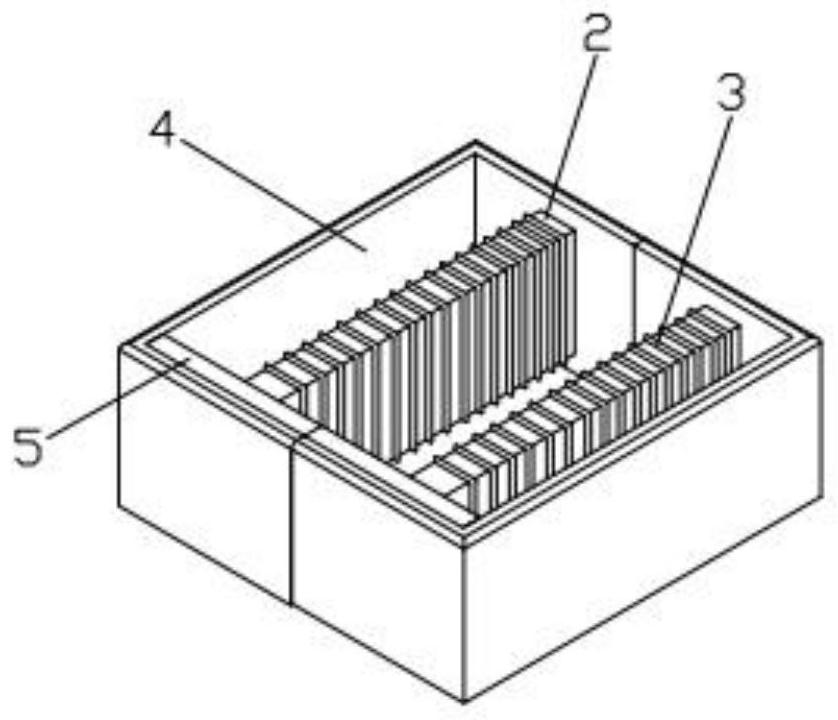

[0026] Such as Figure 1 to Figure 8 An integrated high-frequency magnetic element shown includes a base 1, a first magnetic element, a second magnetic element, and a cover structure. The first magnetic element includes two sets of first magnetic cores 2, a first coil 3 wound on the first magnetic cores 2, and a U-shaped vertical plate 4. The first magnetic cores 2 It is arranged inside the vertical plate 4 , and it should be noted that an extended protective plate 5 is provided at the head of the vertical plate 4 . The second magnetic element includes an annular second magnetic core 6 and a second coil 7 wound on the second magnetic core 6 .

[0027] The base 1 includes a first mounting portion 8 and a second mounting portion 9 snapped to the first mounting portion 8, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com