Method of forming semiconductor device

A semiconductor and conductive technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

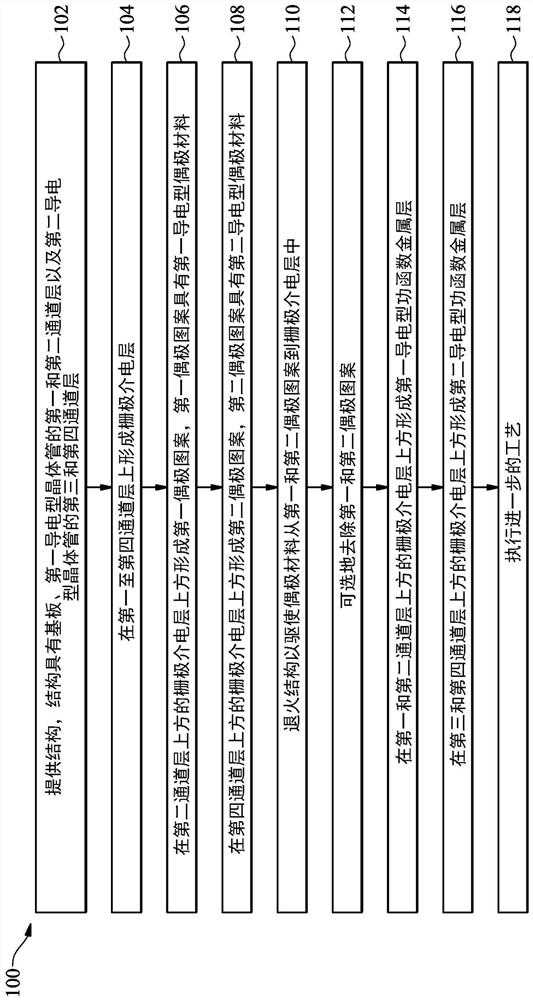

Method used

Image

Examples

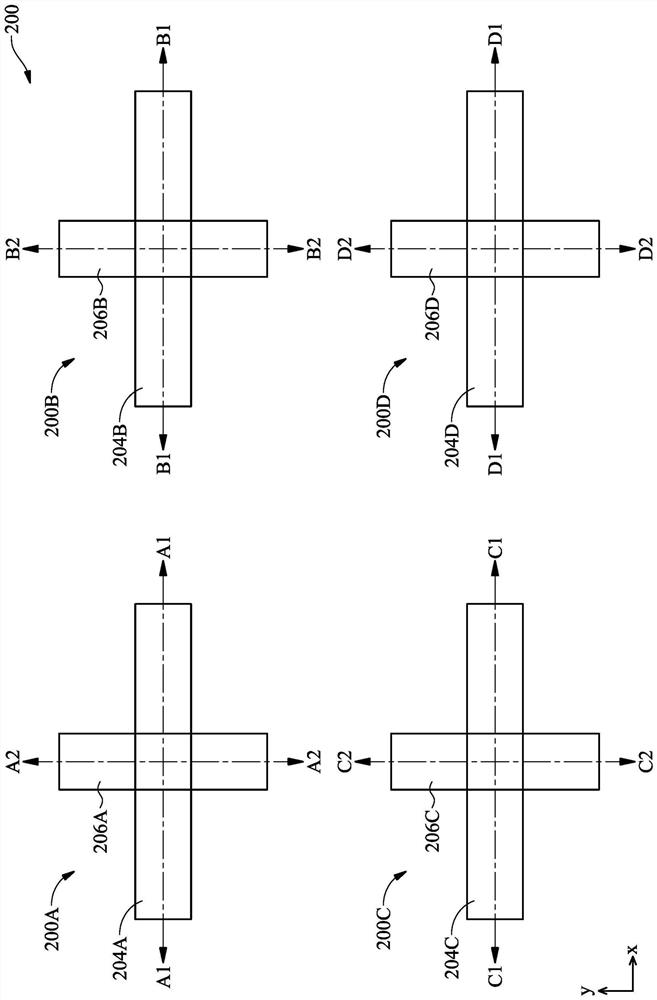

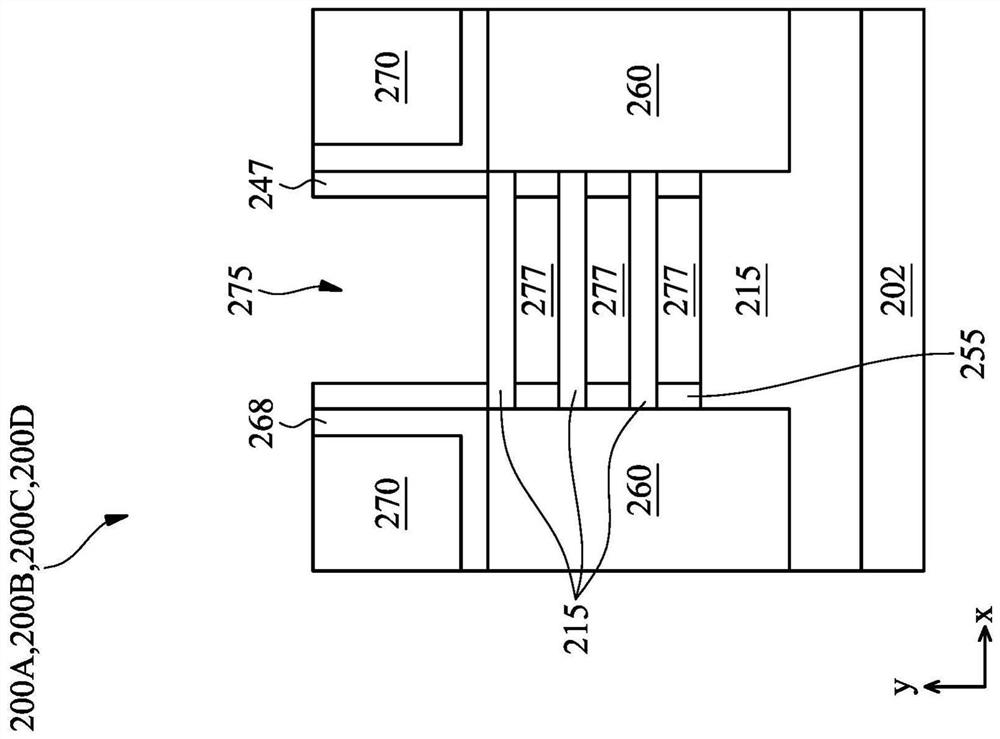

Embodiment Construction

[0077] The following provides a number of different embodiments or examples for implementing different components of an embodiment of the disclosure. Specific examples of components and configurations are described below to simplify embodiments of the present disclosure. Of course, these are just examples and are not intended to limit the embodiments of the present disclosure. For example, the dimensions of the elements are not limited to the disclosed ranges or values, but may depend on process conditions and / or desired characteristics of the device. In addition, in the following description, it is mentioned that the first part is formed on or on the second part, which may include an embodiment in which the first part and the second part are formed in direct contact, and may also include an embodiment where the first part and the second part are formed. An embodiment in which an additional part is formed between the second part so that the first part and the second part may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com