Connector assembly

A technology of connector components and connectors, which is applied in the direction of connection, electrical components, coupling devices, etc., can solve the problems of increasing the difficulty of circuit board manufacturing and the inability to meet the versatility of connector components, and achieve the effect of saving processing steps and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

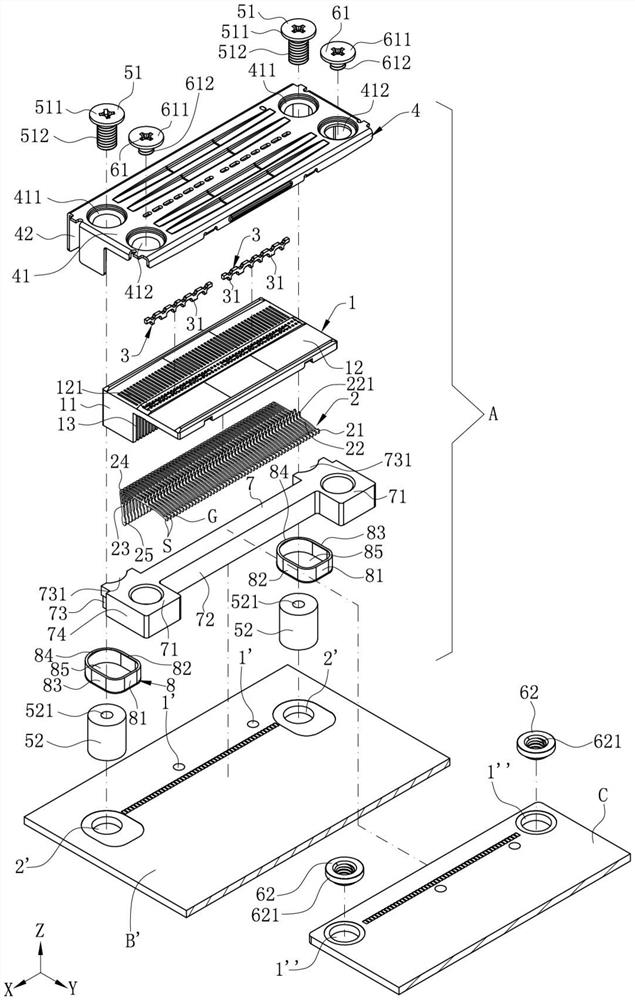

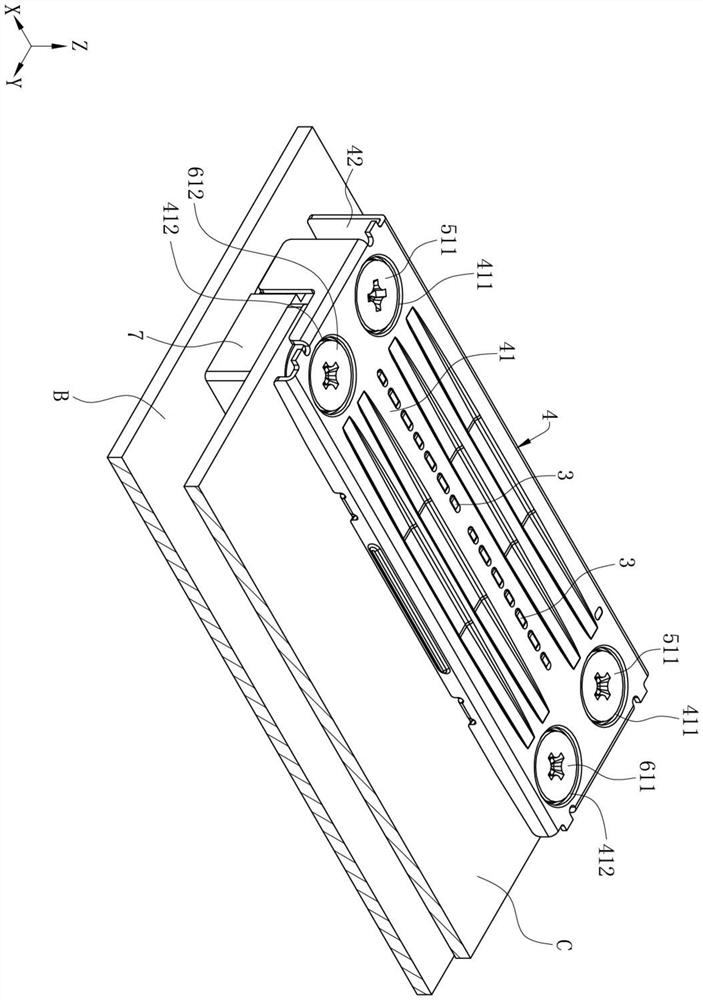

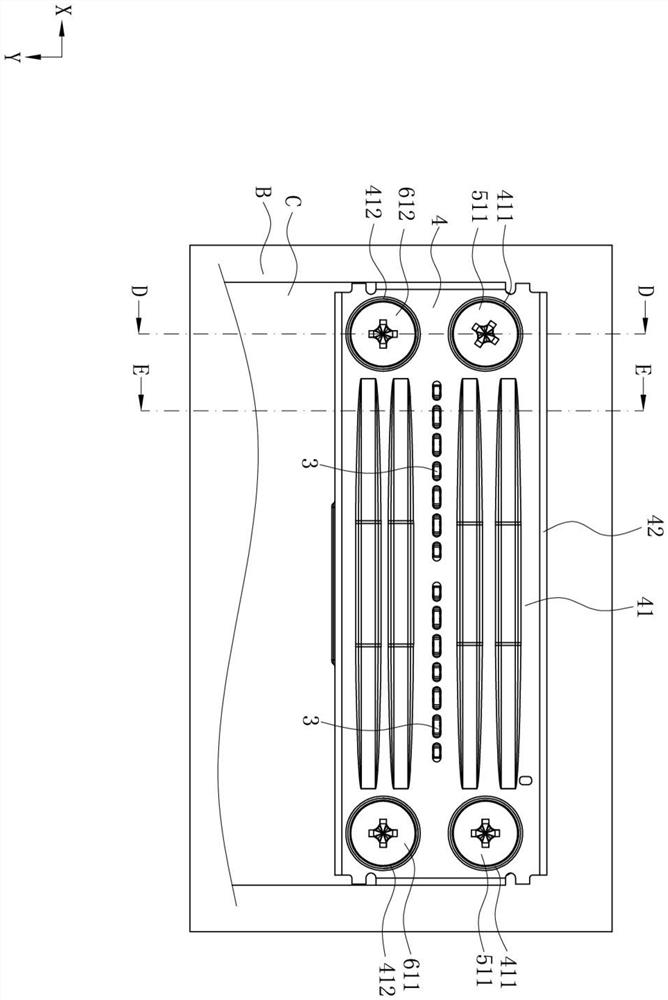

[0028] In order to facilitate a better understanding of the purpose, structure, features and functions of the present invention, the connector assembly A of the present invention will now be further described in conjunction with the drawings and specific embodiments.

[0029] Such as Figure 1 to Figure 8 As shown, the connector assembly A of the present invention defines a front-to-back direction, a left-to-right direction (arrangement direction of a plurality of terminals 2 ) and a vertical direction perpendicular to the front-to-back direction. To facilitate the understanding of the drawings, the forward direction in the front-back direction is the positive direction of the X-axis, the rightward direction in the left-right direction is the positive direction of the Y-axis, and the upward direction in the up-down direction is the positive direction of the Z-axis.

[0030] Such as Figure 1 to Figure 8 As shown, the connector assembly A of the present invention is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com