Dual-channel switched reluctance fault-tolerant motor

A switched reluctance, dual-channel technology, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of poor versatility, and achieve the effect of compact structure, clear working principle, easy to understand and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

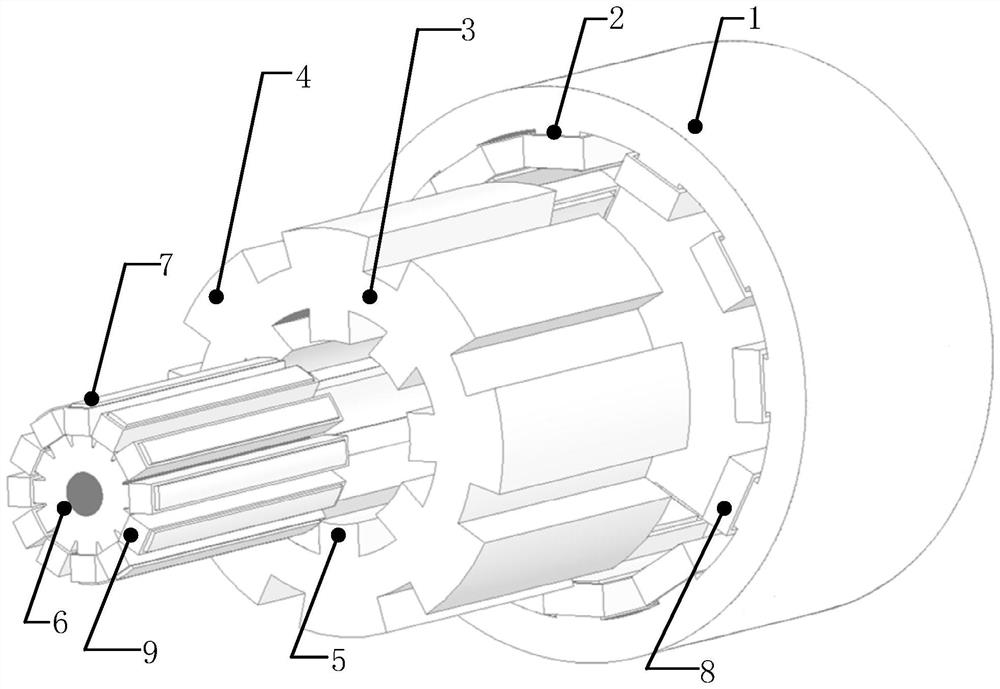

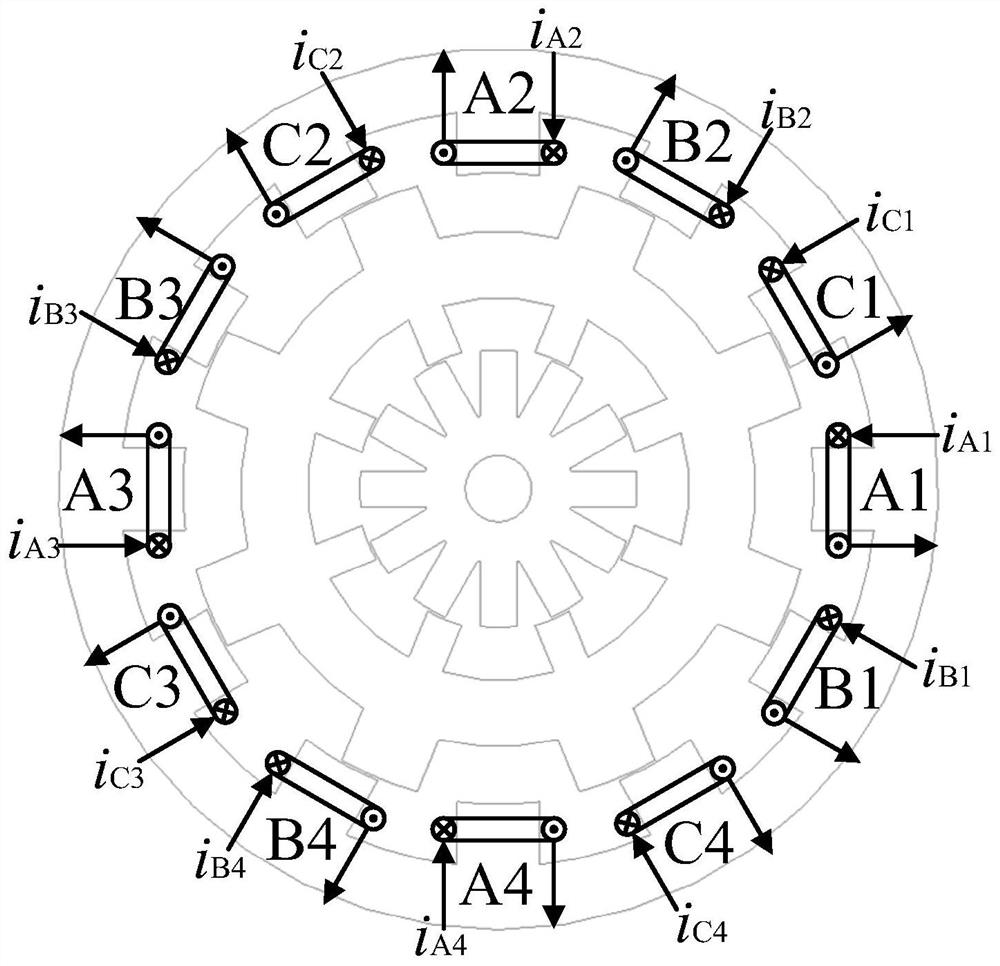

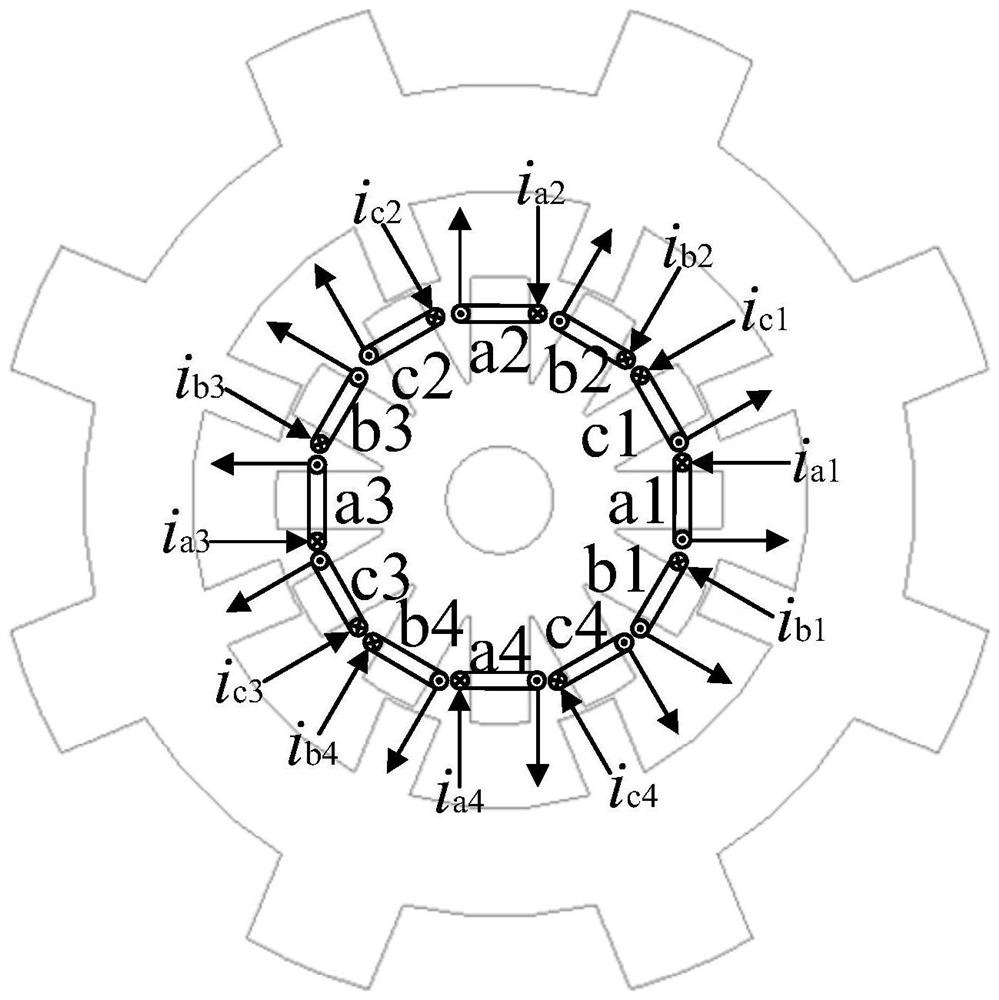

[0040] see figure 1 , the schematic diagram of the structure of the dual-channel switched reluctance fault-tolerant motor of the present invention adopts a four-salient pole structure with 12 / 8 / 8 / 12 poles, including an outer stator core 1, a main winding pole 2, a rotor core 3, and a rotor outer salient pole 4 , rotor inner salient pole 5, inner stator core 6, secondary winding pole 7, main winding 8, secondary winding 9, outer stator core 1, rotor core 3, inner stator core 6 are nested concentrically from outside to inside.

[0041] Twelve main winding poles 2 are arranged at equal intervals on the inner wall of the outer stator core 1, eight rotor outer salient poles 4 are arranged at equal intervals on the outer wall of the rotor core 3, and eight rotor inner salient poles 5 are arranged at equal intervals on the On the inner wall of the rotor core 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com