Automatic production assembly line for Bluetooth earphones

A Bluetooth headset and assembly line technology, applied in loading/unloading, transportation and packaging, sensors, etc., can solve the problems of low operation accuracy, low efficiency, and many steps, and achieve high assembly process, high efficiency, and labor cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

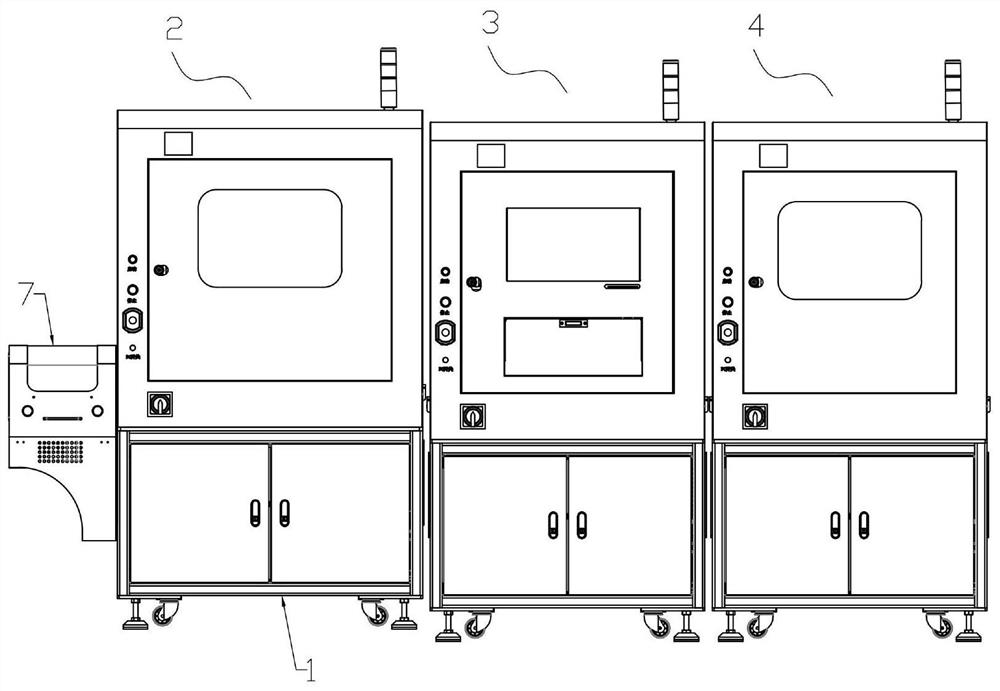

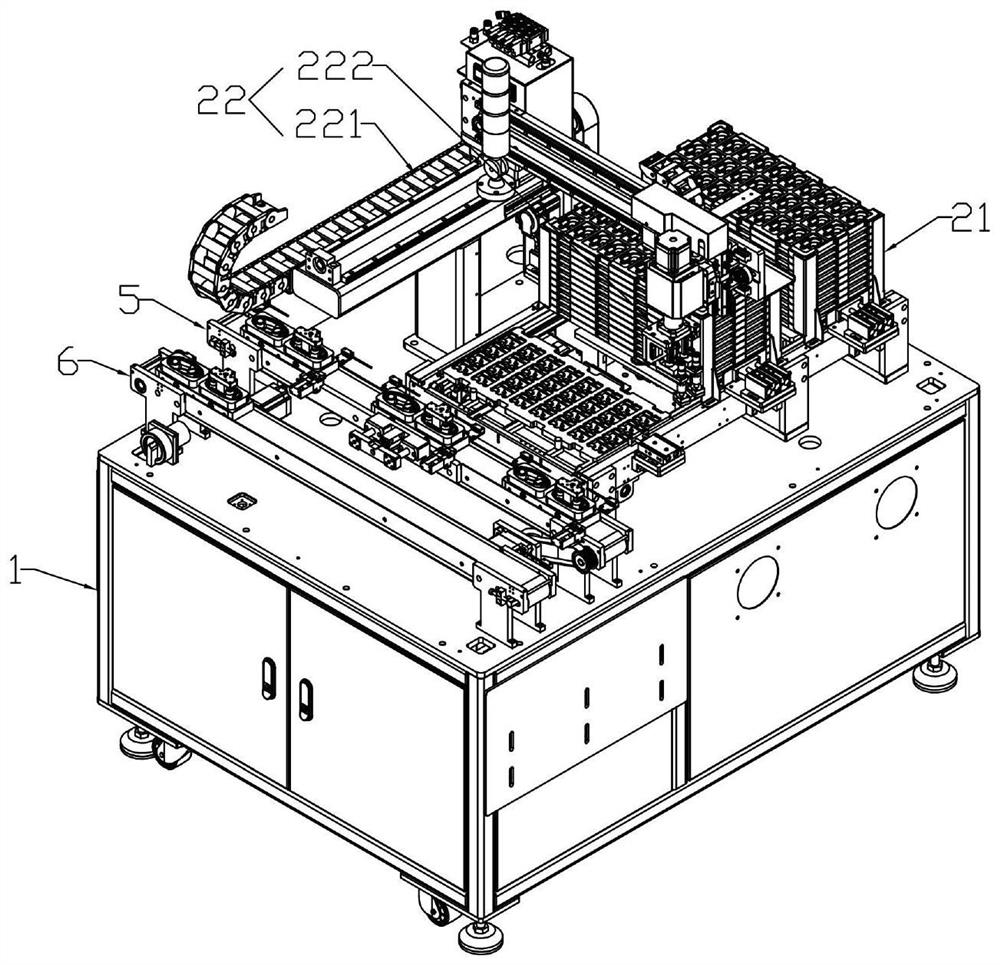

[0033] Such as Figure 1-15 As shown, a bluetooth headset automatic production and assembly line, including a box body 1 and a feeding module 2, a magnet assembly module 3 and a dispensing module 4 installed on the box body 1 in sequence from left to right;

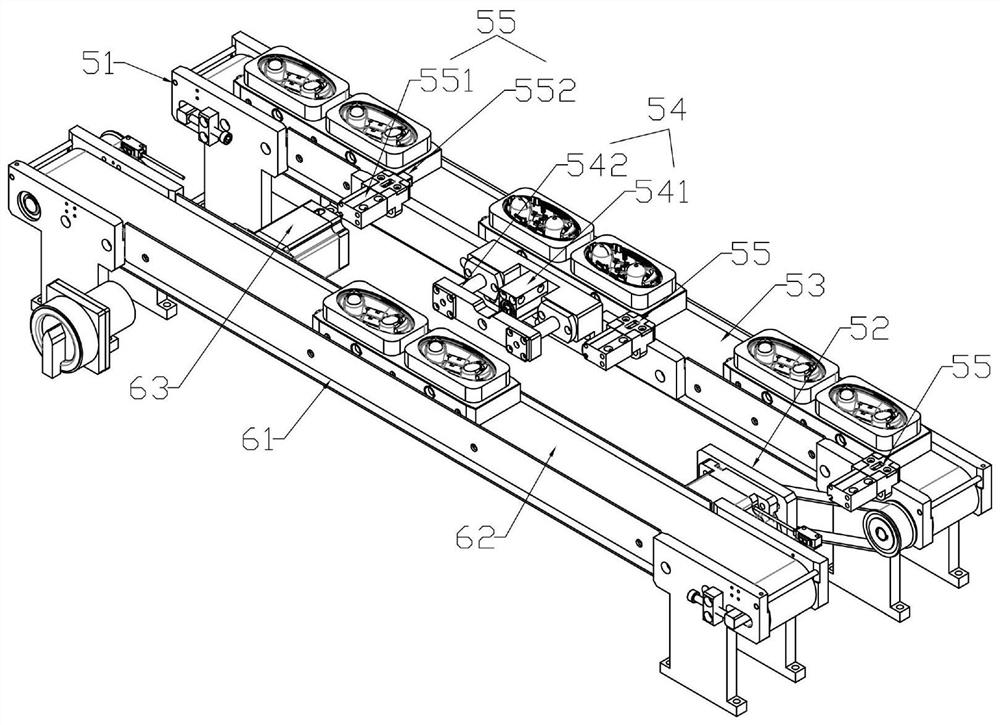

[0034] It also includes three sets of carrier feeding mechanisms 5 that have the same structure and are respectively arranged on the feeding module 2, the magnet assembly module 3 and the front side of the dispensing mold.

[0035] Such as figure 2As shown, a carrier is placed on the carrier feeding mechanism 5; in this design, there are two product placement positions on the carrier, and each carrier can place two products (the product of this design is an earphone bottom shell); The carrier feeding mechanism 5 is used to control the carrier to be transported from left to right; the carrier feeding mechanism 5 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com