Method for the removal of at least one contaminant from an aqueous liquor or a gas

A technology for water-based liquids and pollutants, which is applied in the directions of water pollutants, liquid-solid mixing, separation methods, etc., and can solve problems such as frequent cleaning and blockage of injectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0245] The examples described below serve to illustrate the invention.

example 1

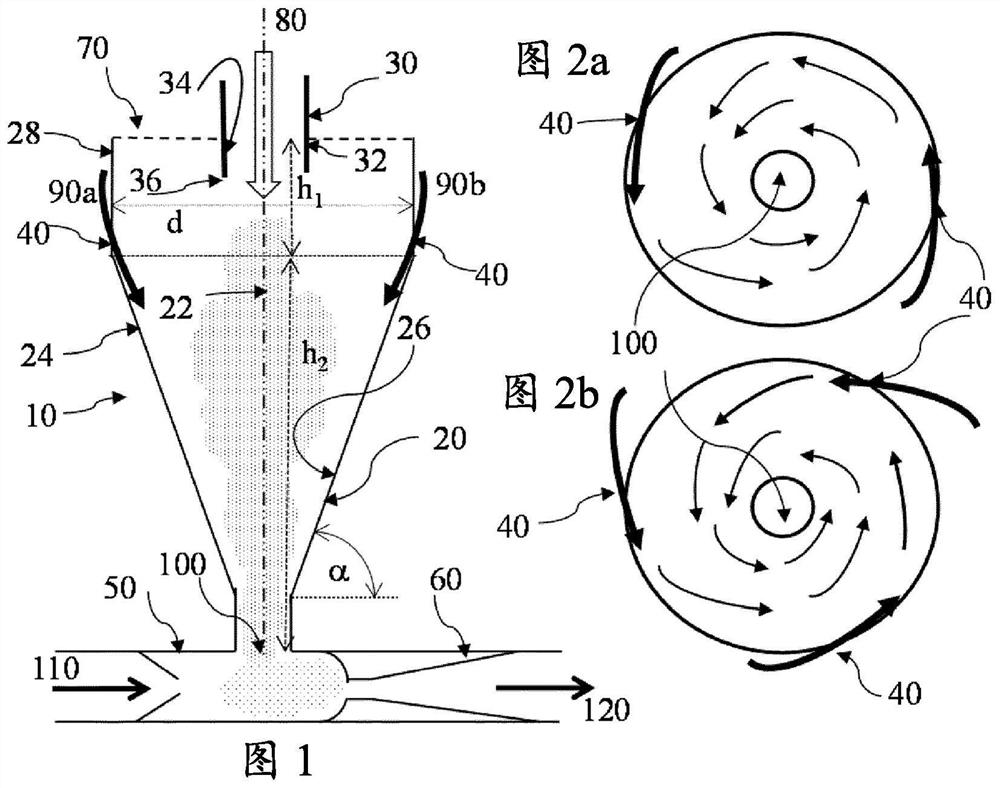

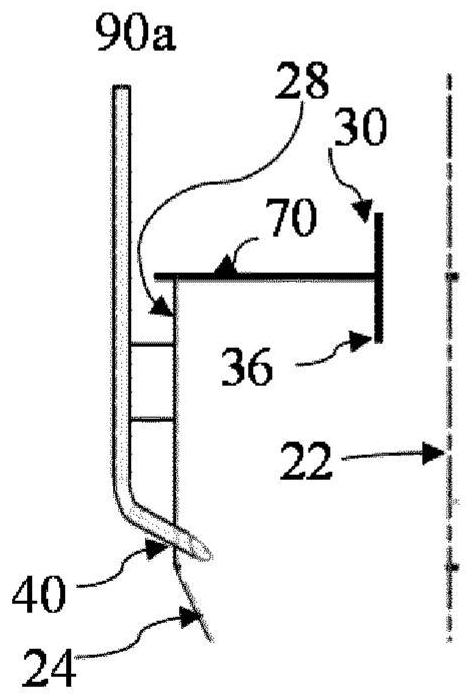

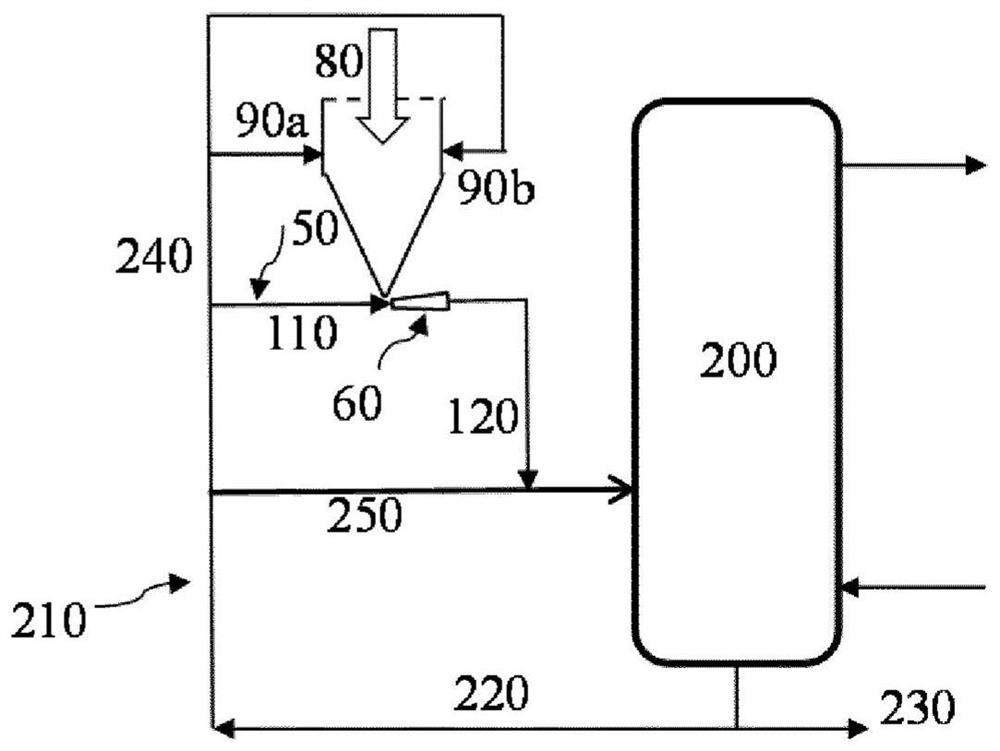

[0247] Such as figure 1 The unit shown was used for this test.

[0248] Heavy soda ash solution using the equipment at various temperatures: 20°C, 30°C, 40°C and 50°C, using a solid flow rate of 1000kg / hr of heavy soda ash, 9.4-9.8m in the conduit including the injector 3 / hr of water flow, and 1.2-1.6m divided into two side streams of equal flow (flowing tangentially onto the inner wall of the frusto-conical part of the pre-wetting chamber) 3 / hr of water (liquid) to prepare. Under these operating conditions, no clogging or skinning problems were observed on the inner surface of the solid feed tube, and no clogging of the fluid outlet at the bottom of the chamber or in the injector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com