Coloring device and coloring method for cellulose casing filled sausage product

A cellulose casing and filling technology, which is applied in the direction of food ingredients as color, application, sausage production, etc., can solve the problems of waste of resources and other problems, and achieve the effects of avoiding waste, improving utilization rate, and good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

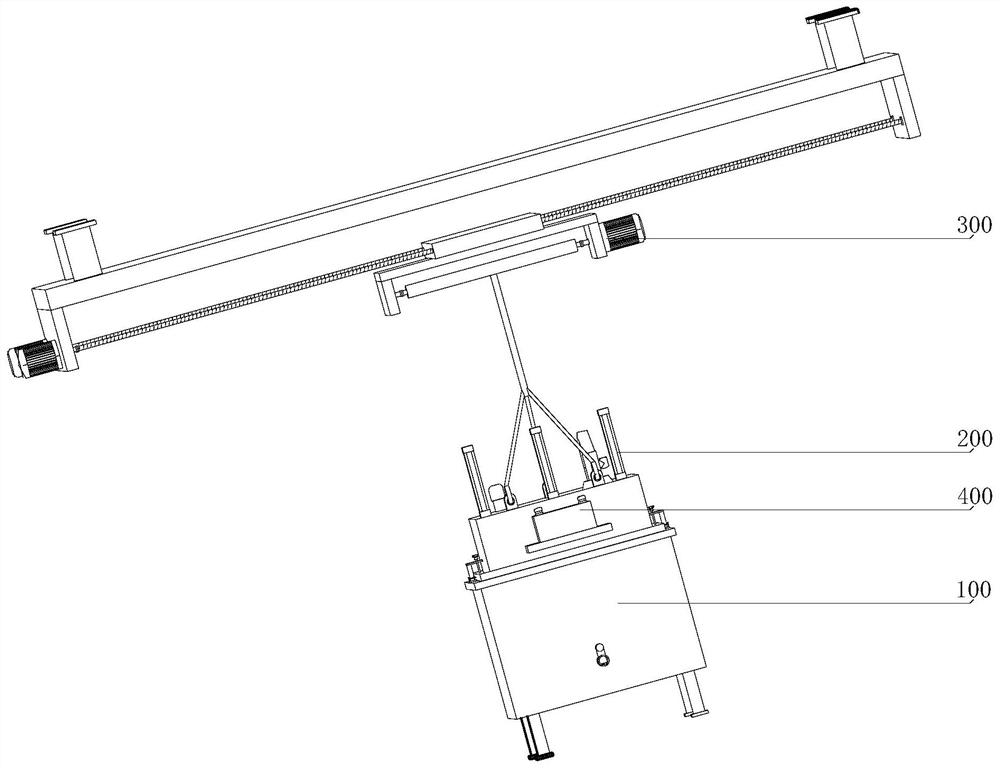

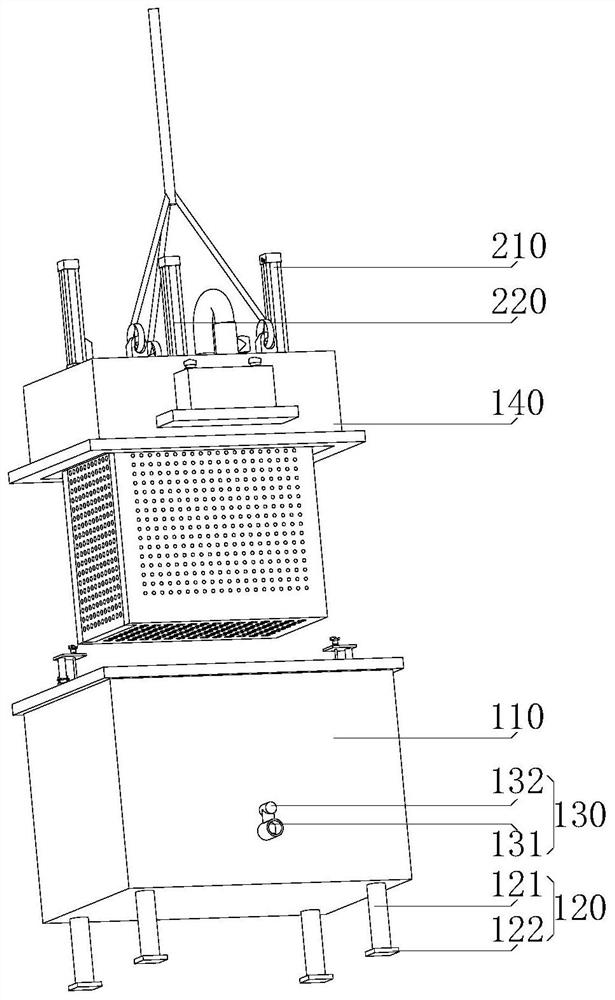

[0051] see Figure 1-Figure 9 , the present invention provides a technical solution: the coloring device for sausage products filled with cellulose casings includes a base assembly 100, an immersion assembly 200, a lifting assembly 300 and a power generation assembly 400, and the immersion assembly 200 and the power generation assembly 400 are both It is fixed on the base assembly 100 to facilitate utilization of steam, and the base assembly 100 is fixed on the lifting assembly 300 for lifting the upper cover 140, effectively preventing waste of steam and improving resource utilization.

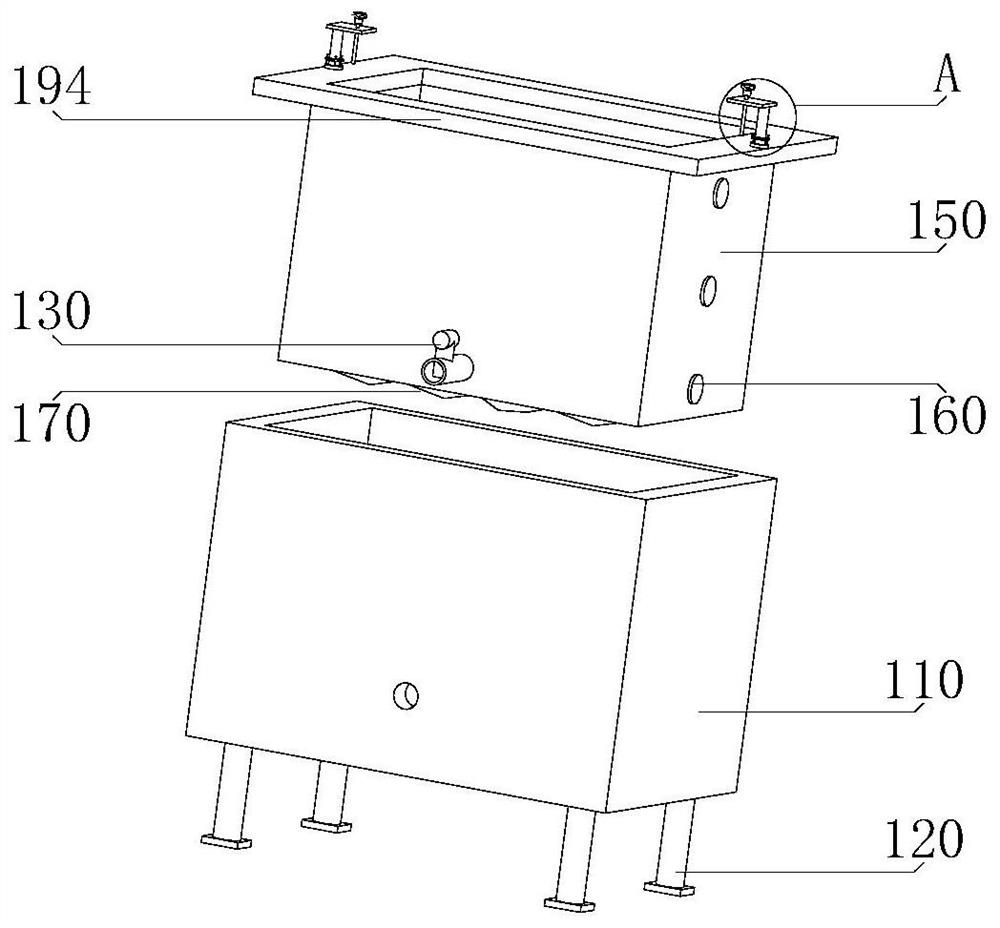

[0052] see Figure 1-5 , the basic assembly 100 includes a first pot body 110, a support column 120, a drain pipe 130, an upper cover 140, a second pot body 150, an electric heating tube 170, a first rotating member 180, an L-shaped plate 190, a circular plate 191, a second A threaded rod 192, the second threaded rod 193 and the first connecting plate 194, the support column 120 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com