Graduation filling machine with automatic medicine powder recycling function

An automatic recovery and filling machine technology, which is applied in the direction of drug delivery, pharmaceutical formula, capsule delivery, etc., can solve the problems of drug powder production of finished drugs, increased working hours, and dusty countertops, etc., to achieve simple and reliable structure, improve utilization rate, reduce Effects of Time and Intensity of Labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

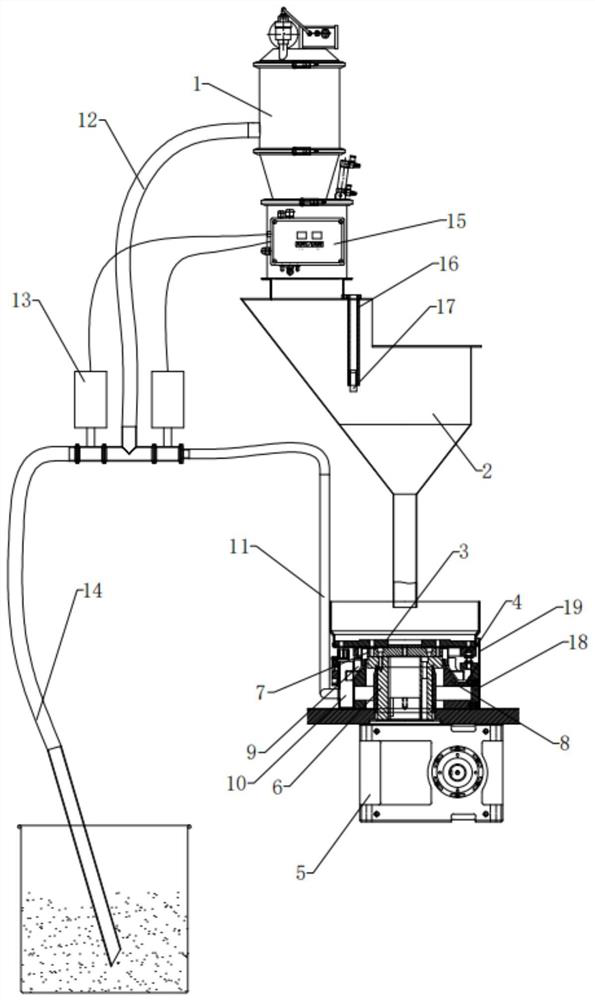

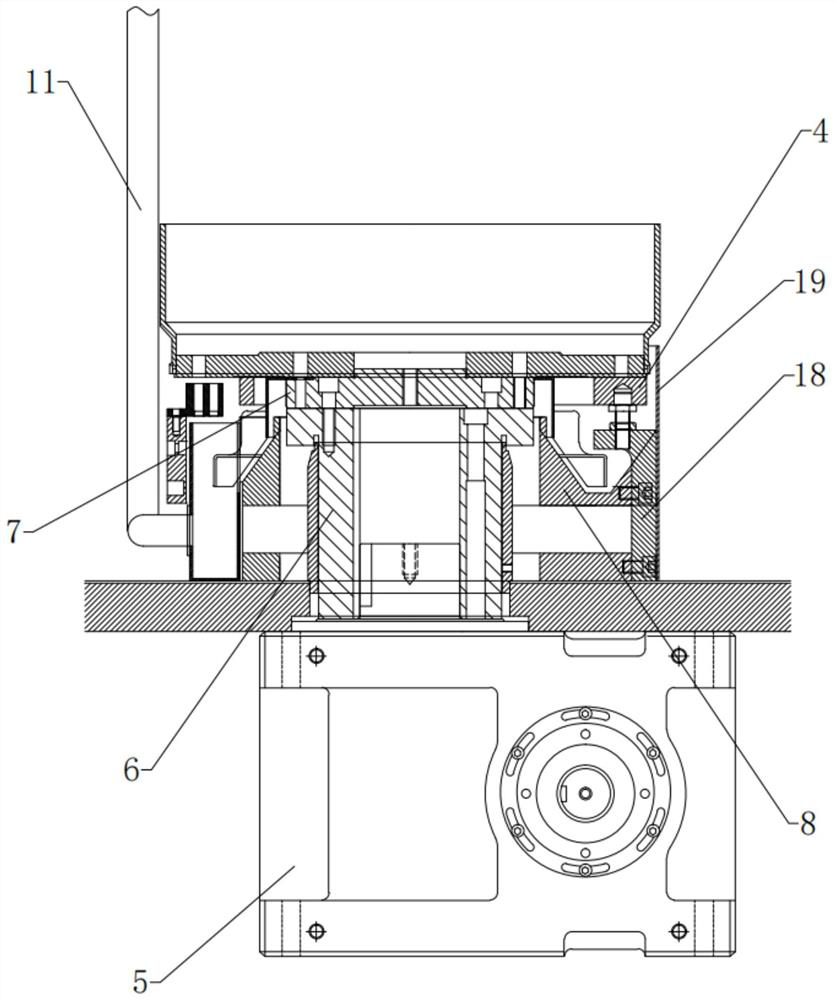

[0021] Embodiment: according to specification Figure 1-3 It can be seen that this case is an indexing filling machine with the function of automatic powder recovery, including a vacuum feeder 1, a powder hopper 2, a metering disc 3, a copper ring 4, an indexing box 5, an automatic powder recovery mechanism, and a vacuum feeder. The bottom end of 1 is connected to the powder hopper 2, and the connection relationship and position relationship are as follows;

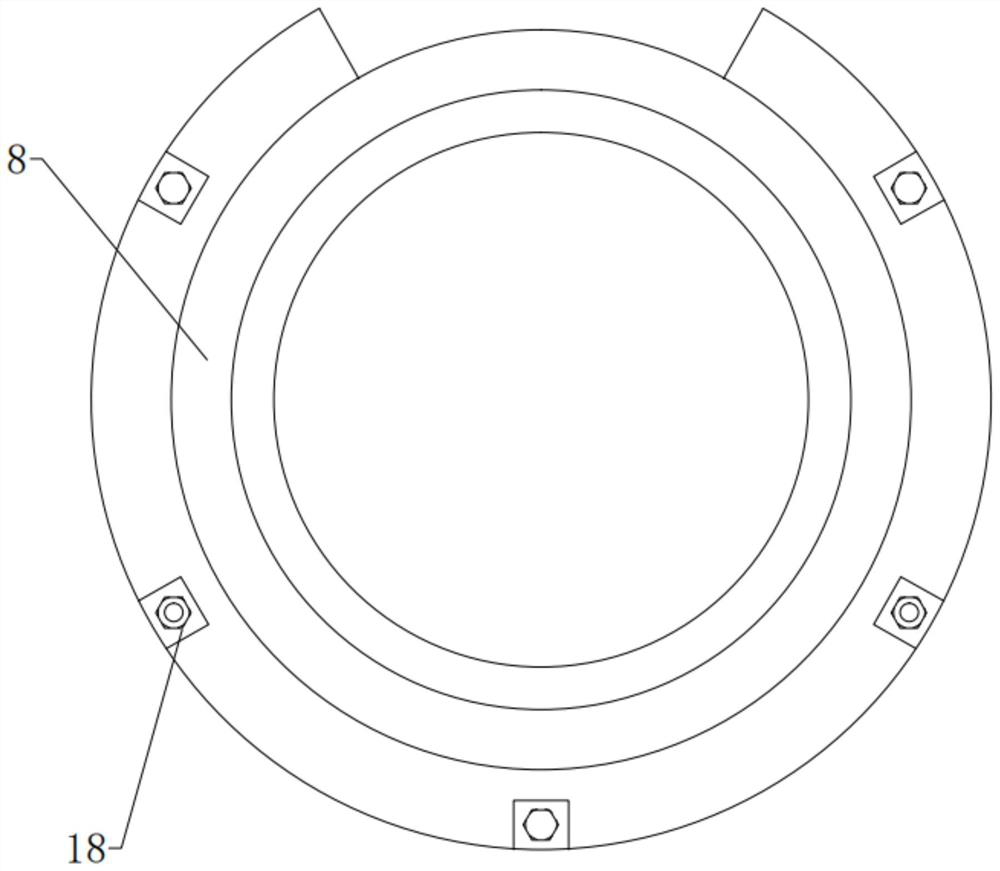

[0022] The bottom end of the medicine powder hopper 2 extends out of the feeding pipe, and the bottom end of the feeding pipe leads into the metering disk 3, the copper ring 4 is installed on the bottom surface of the metering disk 3, and the lower part of the copper ring 4 is provided with an automatic powder recovery mechanism;

[0023] According to the manual attached Figure 1-3 It can be seen that the above-mentioned automatic powder recovery mechanism includes: the shaft head 6, the shaft head end cover 7, the powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com