Wet flue gas desulfurization gypsum dehydration system and control method

A technology of wet desulfurization and control method, which is applied in the direction of separation method, chemical instrument and method, filtration circuit, etc. It can solve the problems of complicated operation steps, impurities in slurry, and ineffective use of reaction liquid, etc., and achieve simplified operation steps , avoid safety accidents, and effectively use the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

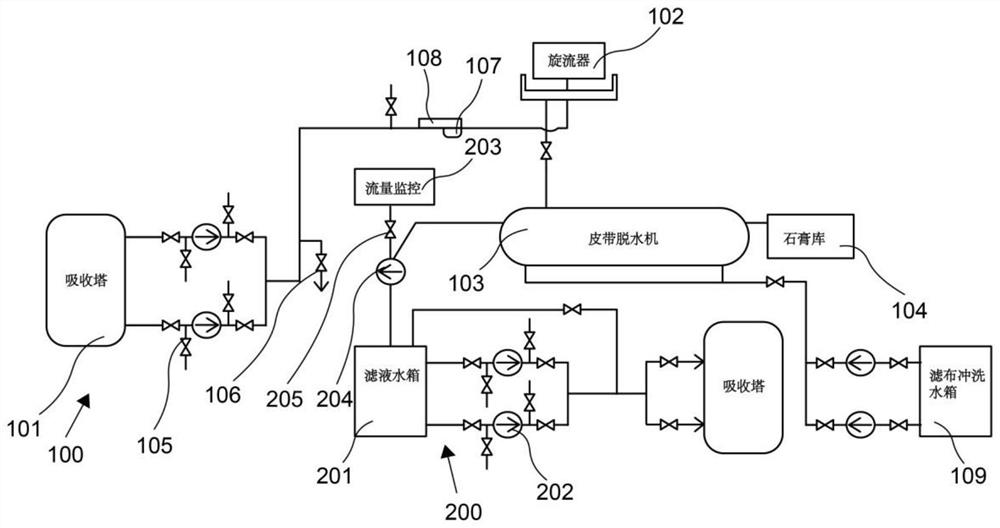

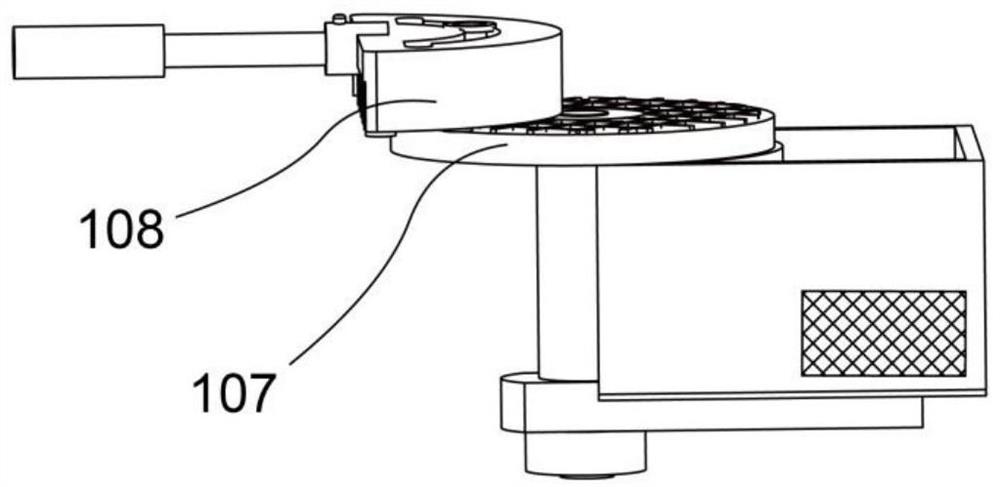

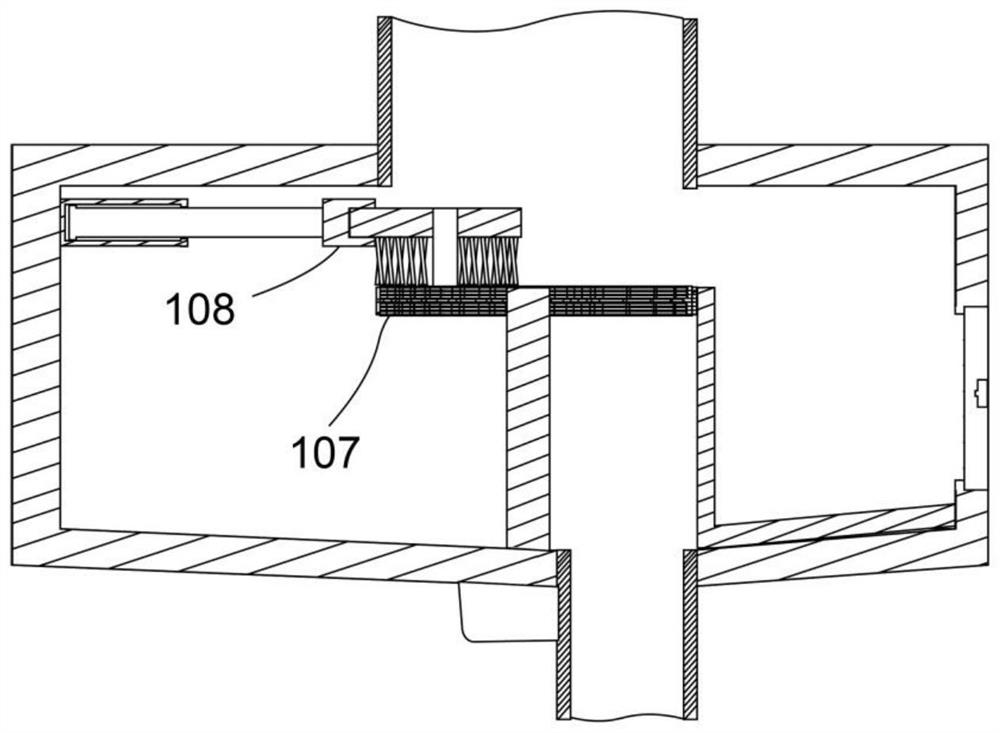

[0029] refer to Figure 1-4 , a wet desulfurization gypsum dehydration system, comprising, dehydration module 100, including absorption tower 101, cyclone 102, belt dehydrator 103 and gypsum storehouse 104; and filtrate recovery module 200, including filtrate connected with belt dehydrator 103 Water tank 201, filtrate water pump 202 and flow monitoring block 203 arranged on filtrate water tank 201, absorption tower 101, cyclone 102, belt dehydrator 103, gypsum storage 104, filtrate water tank 201, filtrate water pump 202 and flow monitoring block 203 are connected by pipeline; between the absorption tower 101 and the cyclone 102, a gypsum discharge valve 105 and a drain valve 106 are arranged; the filtrate water tank 201 is connected with the absorption tower 101, and a Vacuum pump 204, vacuum pump 204 is provided with vacuum pump sealing water valve 205; Between cyclone 102 and belt dehydrator 103, is provided with impurity removal block, impurity removal block includes filte...

Embodiment 2

[0037] refer to Figure 1-4 , This embodiment is different from the first embodiment in that: this embodiment discloses a wet desulfurization gypsum dehydration control method, which has two circulation modes:

[0038] When the water flow of the flow monitoring block 203 does not alarm, the wet desulfurization gypsum dehydration system starts cycle I;

[0039] When the water flow monitoring block 203 alarms when the water flow is too low, the wet desulfurization gypsum dehydration system starts cycle II.

[0040] The start-up cycle Ⅰ of the wet desulfurization gypsum dehydration system includes:

[0041] When the wet desulfurization gypsum dehydration system does not detect that the water flow value passing through the flow monitoring block 203 is too low, it first uses the filter cloth flushing water tank 109 to flush the belt dehydrator 103, the slurry flows out from the absorption tower 101, and the cyclone 102 performs preliminary separation treatment on the slurry, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com