Assembly equipment for integrated circuit structures

A technology for assembling equipment and integrated circuits, applied in circuits, welding equipment, auxiliary welding equipment, etc., can solve the problems of scalding integrated circuits, reducing work efficiency, increasing equipment downtime, etc., to ensure the quality of composition and welding accuracy. , The effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

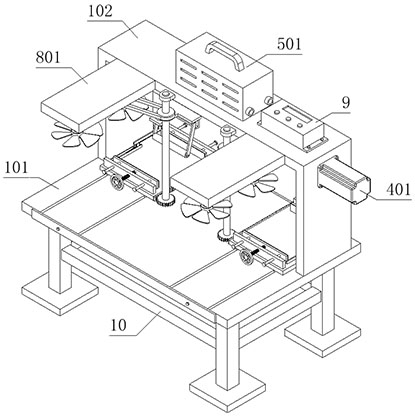

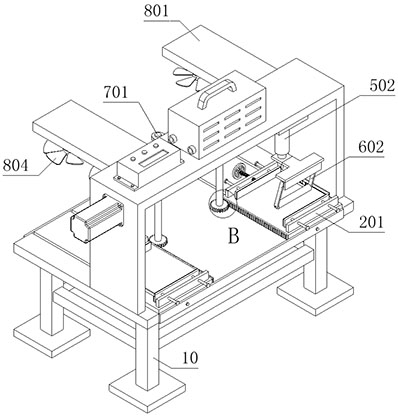

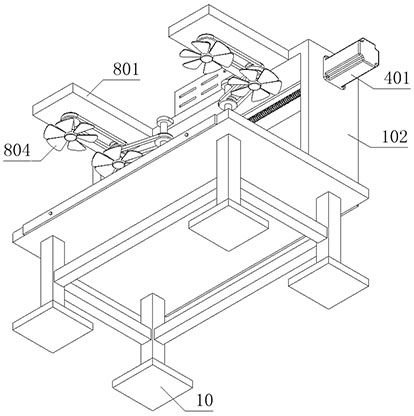

[0090] as attached figure 1 To attach Figure 24 Shown:

[0091] The present invention provides assembly equipment for integrated circuit structures, including a bracket 10; a mounting mechanism 1 is installed on the top of the bracket 10, and two sets of clamping devices 2 are installed on the mounting mechanism 1, and the outer sides of the two sets of clamping devices 2 are installed Connecting part 3 is arranged; Moving mechanism 4, and moving mechanism 4 is installed on the mounting mechanism 1, and the bottom of moving mechanism 4 is equipped with welding device 5, and the rear side of welding device 5 is equipped with dust removal device 6, and the top of mounting mechanism 1 The controller 9 is installed; the driving part 7 is provided with two groups, and the two groups of driving parts 7 are installed on the installation mechanism 1, and two groups of cooling devices 8 are installed on the front side of the installation mechanism 1.

[0092] as attached Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com