Underwater granulator for plastic

An underwater granulator and plastic technology, which is applied in plastic recycling, mechanical equipment, engine components, etc., can solve the problems affecting the quality of granule forming and cutter disturbance, so as to improve the quality of granule forming and reduce the excessive wear of the cutter , Increase the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

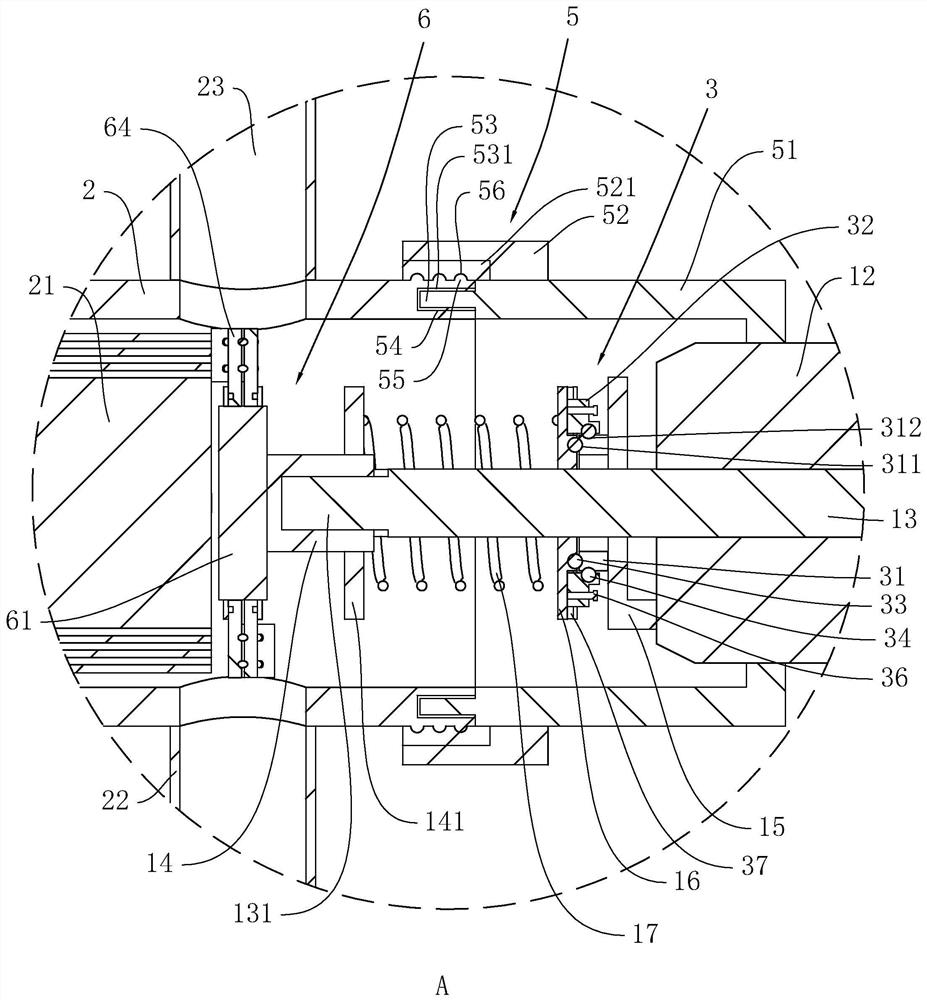

[0035] The following is attached Figure 1-5 The application is described in further detail.

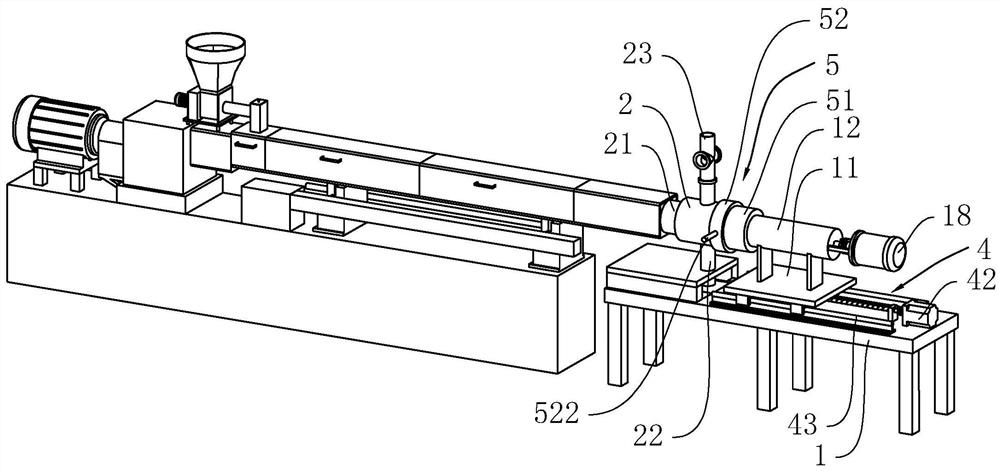

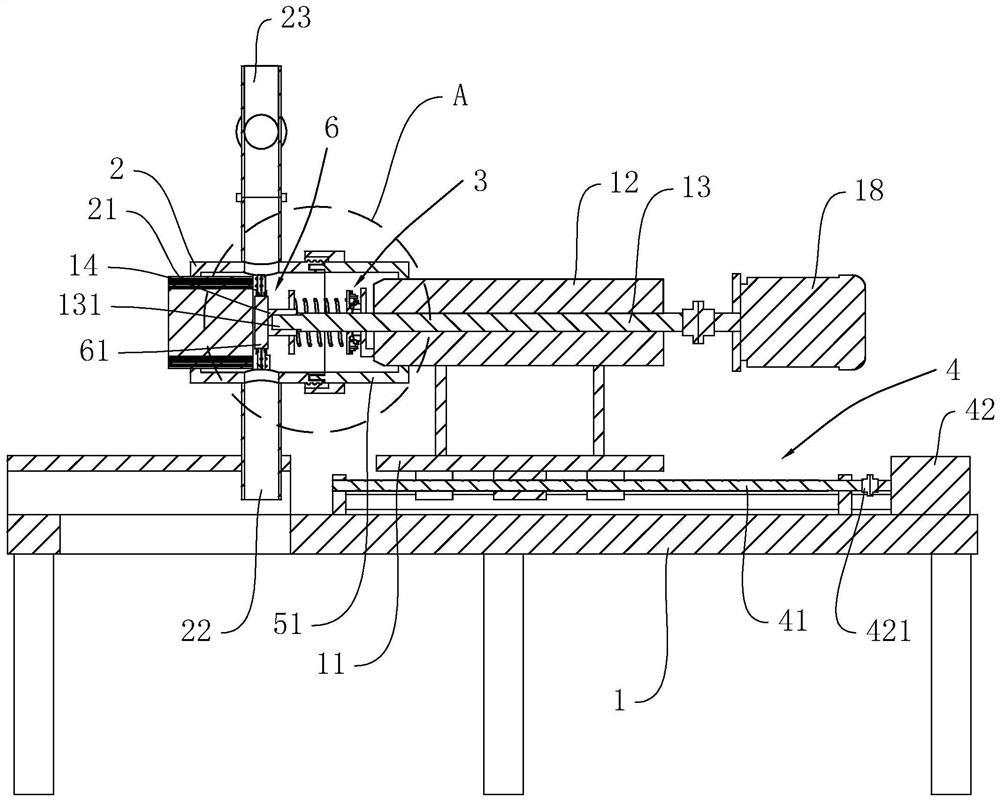

[0036] The embodiment of the present application discloses a plastic underwater pelletizer. Such as figure 1 and figure 2 , the plastic underwater pelletizer includes a frame 1, the frame 1 is provided with a sealing cover 2 and a sliding seat 11 which are relatively distributed, and a die head 21 is arranged in the sealing cover 2, and the discharge of the die head 21 and the die barrel of the extruder The mouths are connected, and the die head 21 has a hole for extruding the molten material in the extruder. The sealing cover 2 is provided with a water inlet pipe 22 and an outlet pipe 23 symmetrically distributed along the vertical direction. The sealing cover 2 is provided with a lock. Tight seal 5.

[0037] Such as figure 1 , the sliding seat 11 is horizontally arranged on the frame 1 and is slidably connected along the length direction of the frame 1. The frame 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com