Concrete conveying belt device and its control method

A belt device and belt technology, applied in conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of slow walking, high cost of lifting equipment, and large limitations, so as to prevent cold seams in construction and ensure pouring. Quality, the effect that meets the needs of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

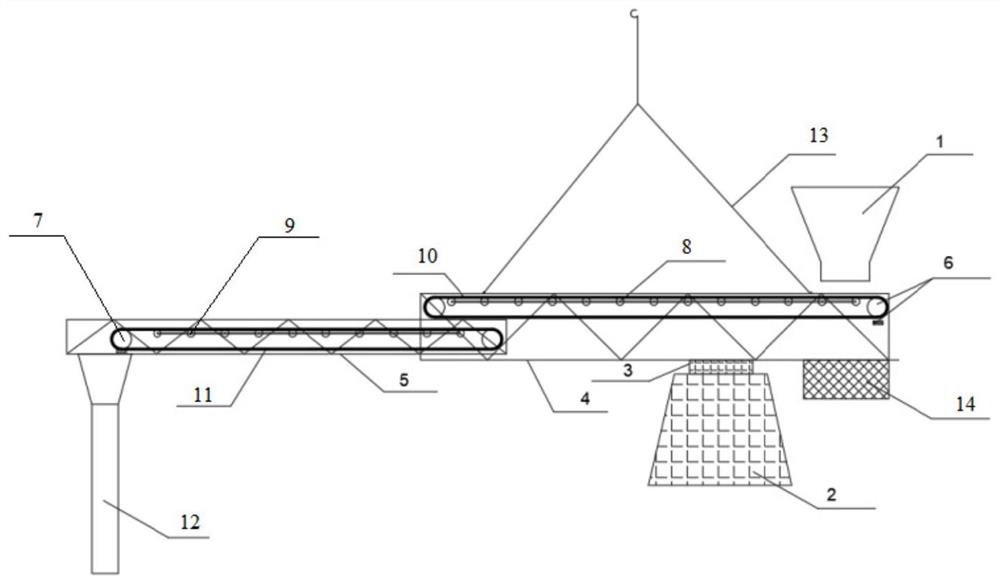

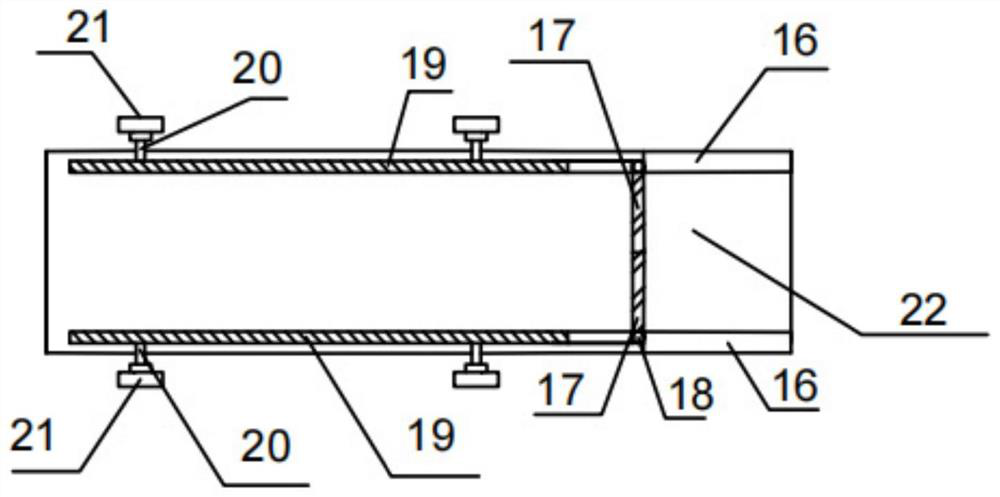

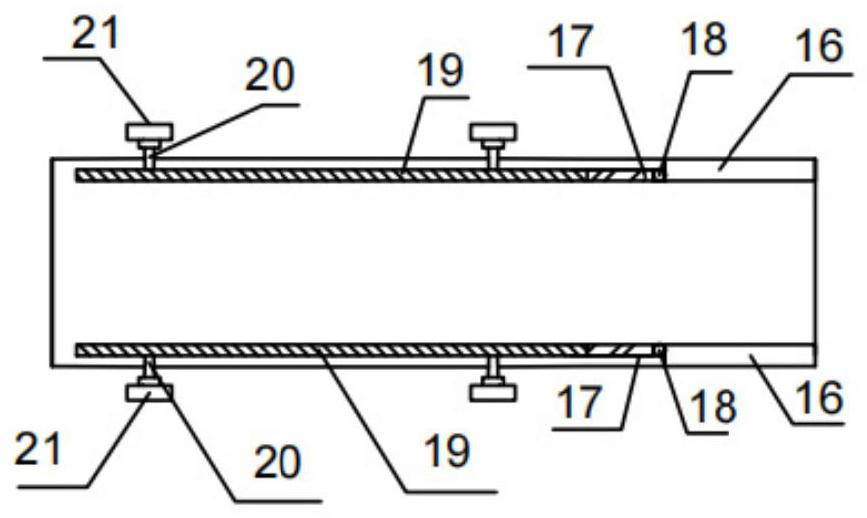

[0040] ginseng figure 1As shown, the present invention provides a concrete conveying belt device, including a feeding mechanism 1, a conveying system and a feeding pipe 15, and the conveying system includes a main truss belt set, a main truss 4, a secondary truss 5, and a secondary truss belt set And the driving device 3, the driving device 3 here can be a rotating motor, the input end of the main truss belt set is located below the feeding mechanism, and the output end of the secondary truss belt set is connected with the described feeding pipe. The main truss belt set is located above the secondary truss belt set, and the output end of the main truss belt set is connected to the input end of the secondary truss belt set; the main truss belt set is installed on the main truss, and the A secondary truss belt set is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com