Method for arranging same-direction inner staggered roadways in extremely close coal seam mining

A roadway layout and extremely close-distance technology, applied in tunnels, ground mining, mining equipment, etc., can solve problems such as leftovers in goafs, concentrated pressure, and obvious mining pressure, so as to improve resource recovery rate and increase economic benefits of enterprises Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

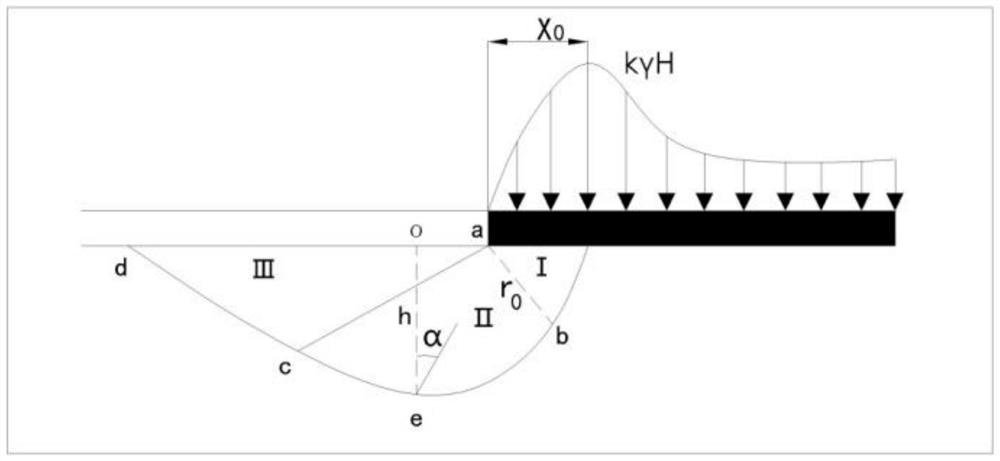

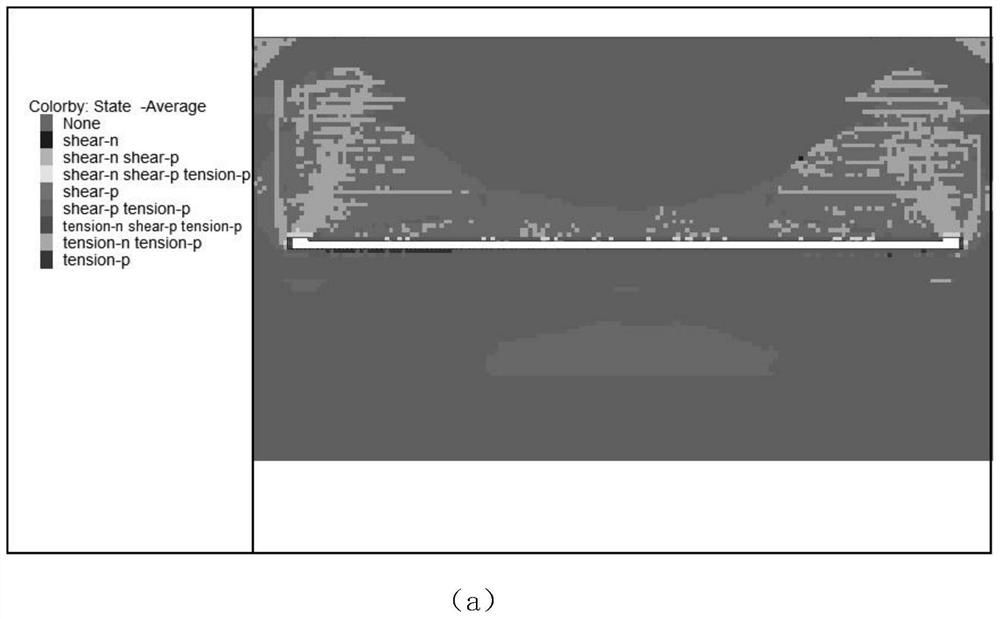

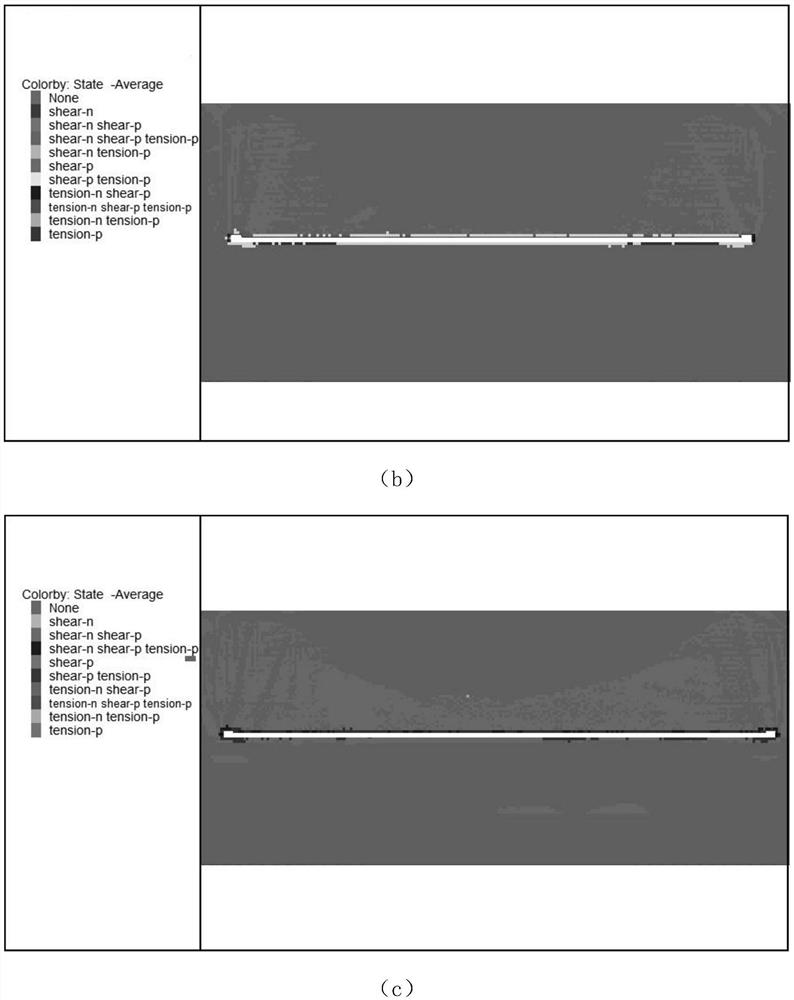

[0105] The present invention analyzes and studies the effect of different working face lengths on floor damage, the influence range of coal pillars with different widths on the floor, and three different roadway layout schemes through theoretical calculation and numerical simulation comprehensive methods, and makes choices for roadway layout parameters. It has laid a solid foundation for roadway support and cost saving.

[0106] Destructive analysis of post-mining floor in upper coal seam

[0107] In the descending mining sequence of short-distance coal seams, the coal pillars left behind after the mining of the upper coal seam will have a destructive effect on its floor strata, which in turn will cause the roof of the lower coal seam to be affected by the mining of the upper coal seam. When the roadway is rationally arranged, it is necessary to first analyze the damage depth of the left coal pillar to the floor in the goaf of the upper coal seam and the stress distribution ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com