Engine tail gas treatment system

An exhaust gas treatment and engine technology, which is applied in exhaust gas treatment, engine components, combustion engines, etc., can solve the problems of post-processor poisoning, post-processor scrapping, and increase the cost of post-processor use, so as to prevent poisoning and reduce usage. cost, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

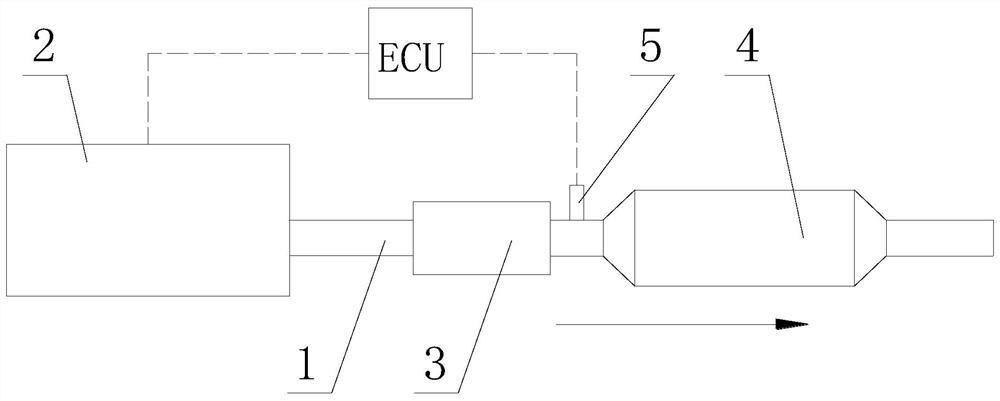

[0021] refer to figure 1 , an engine exhaust gas treatment system, comprising an ECU, an engine 2, a supercharger 3, and an afterprocessor 4 sequentially connected through an exhaust pipe 1, the ECU is connected to the engine 2 by communication, and the connection between the supercharger 3 and the afterprocessor 4 The exhaust pipe 1 is provided with a sulfur dioxide sensor 5 that communicates with the ECU;

[0022] The sulfur dioxide sensor 5 obtains the actual concentration of sulfur dioxide in the exhaust pipe 1 in real time, and sends the actual concentration to the ECU;

[0023] When the actual concentration reaches the first set value, the ECU controls the operation of the engine 2 according to the sulfur dioxide combustion strategy to increase the temperature of the exhaust gas, thereby burning and discharging the sulfur dioxide accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com