Multi-heat-source heat pump type electric vehicle heat management system

A thermal management system and electric vehicle technology, applied in the field of multi-heat source heat pump electric vehicle thermal management system, can solve the problems of low integration, affecting thermal comfort, affecting heat exchange efficiency, etc., to achieve compact structure of components and satisfy comfort Sexual demand, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are given, but the protection scope of the present invention is not limited to the following embodiments.

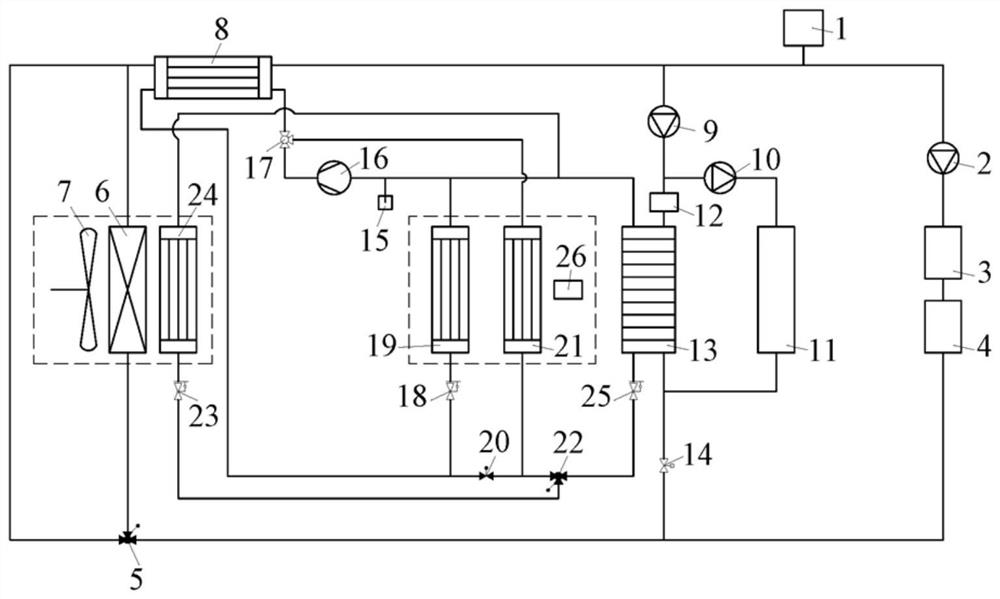

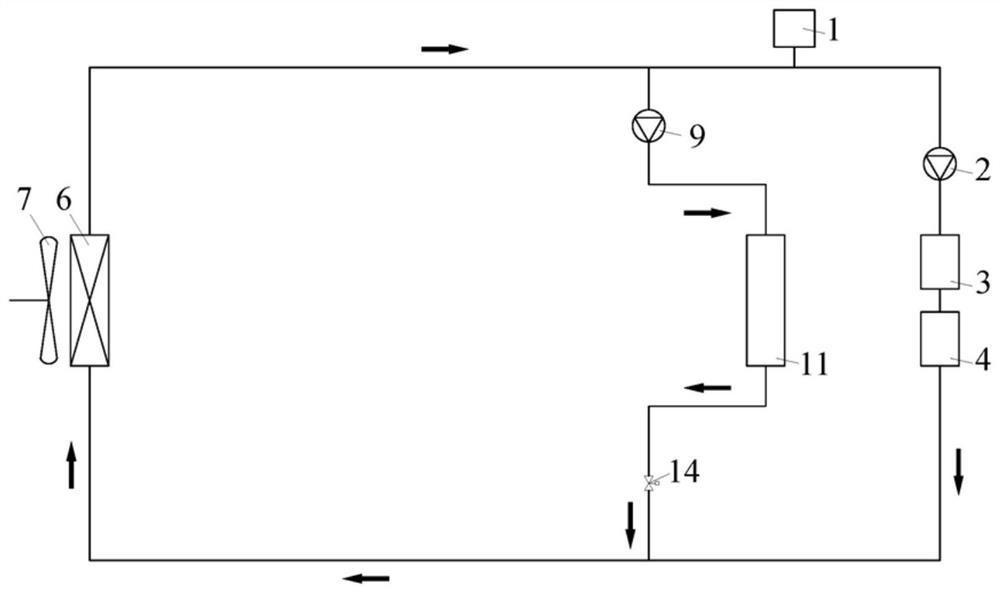

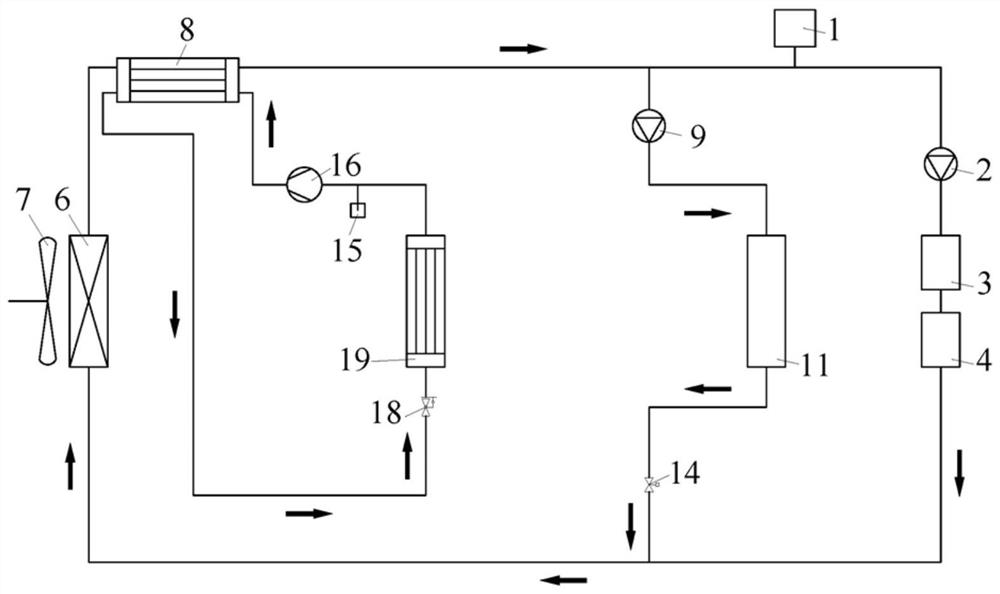

[0037] A multi-heat source heat pump type electric vehicle thermal management system, such as figure 1 As shown, it includes the powertrain thermal management subsystem, the battery thermal management subsystem and the passenger compartment thermal management subsystem, and also includes the water-cooled condenser 8, the joint heat exchange module and the first proportional three-way valve 5, and the joint heat exchange module includes The exterior evaporator 24, the front radiator 6 and the fan 7, the front radiator 6 realizes convection with the exterior evaporator 24 throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap