Single-sheet electrolyte solid oxide fuel battery pack

A technology of solid oxide and fuel cell stacks, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problem of increased processing costs, very high flatness requirements for single cells and bipolar plates, design and processing High requirements and other issues, to achieve the effect of high output voltage and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

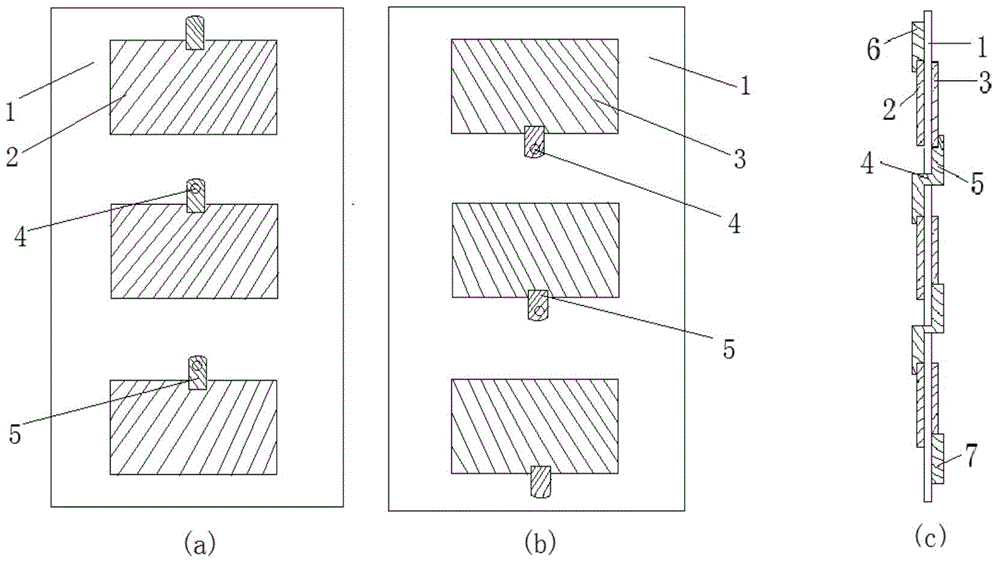

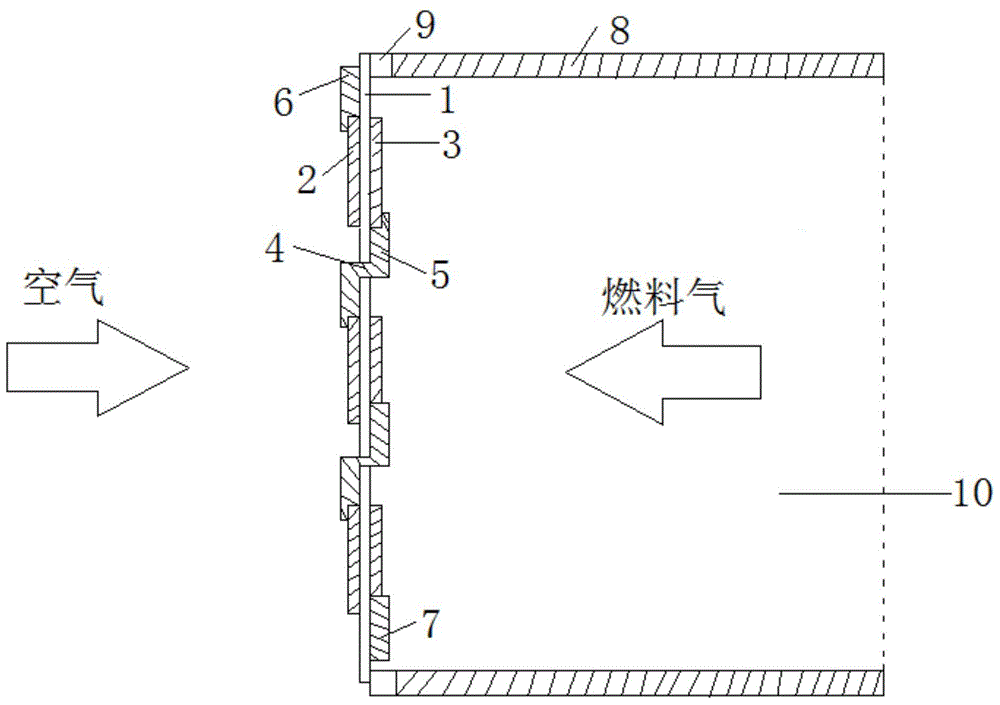

[0027] Embodiment 1 Rectangular monolithic electrolyte SOFC battery pack:

[0028] Such as figure 1 As shown, a rectangular monolithic electrolyte SOFC battery pack consists of an electrolyte sheet 1 , a cathode membrane 2 , an anode membrane 3 and a connecting body 4 . The shape of the electrolyte sheet 1 is rectangular, and the preferred size is 30mm×20mm. The electrolyte material of the electrolyte sheet 1 is yttrium stabilized zirconia (YSZ), which is prepared by tape casting. The shape of the cathode film 2 is rectangular, which can be determined according to the size of the electrolyte sheet 1 and the number of single cells contained in the battery pack. For example, a battery pack with 3 single cells connected in series should be prepared on the electrolyte sheet 1 of 30 mm × 20 mm. The area of the cathode membrane 2 of the battery can be designed to be 14mm×6mm, the distance between adjacent cathode membranes 2 is 3mm, and the distance between the cathode membrane ...

Embodiment 2

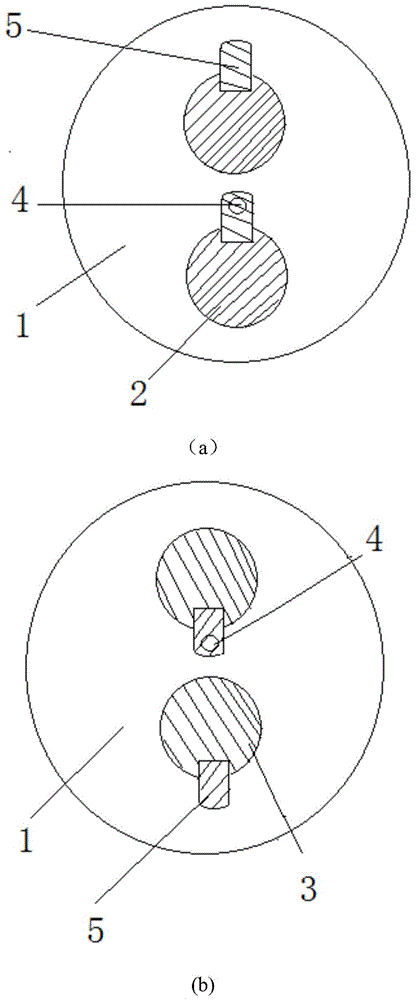

[0036] Example 2: Circular Monolithic Electrolyte SOFC Battery Pack

[0037] Such as image 3 As shown, the main components of a circular monolithic electrolyte SOFC battery pack include an electrolyte sheet 1, a cathode membrane 2, an anode membrane 3, a connecting hole 4 and a connecting body. The shape of the electrolyte sheet is circular, and the size is Φ18×0.4mm. The electrolyte material is yttrium-stabilized zirconia (YSZ), and a single-layer cast film is prepared by tape-casting method, and 13 layers of cast film are superimposed and pressed together by isostatic pressing to obtain an electrolyte green strip. Taking the shrinkage rate (25%) into consideration, the electrolyte green body is cut and punched, and the diameter of the circular green body is Φ24mm.

[0038] The shape of the cathode film 2 is circular, the diameter is Φ6mm, the distance between adjacent cathode films 2 is 2mm, and the distance between the cathode film 2 and the electrolyte 1 is also 2mm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com