Spindle bearing fault detection method and system, equipment and readable storage medium

A spindle bearing and fault detection technology, applied in neural learning methods, instruments, biological neural network models, etc., can solve problems such as poor fault feature extraction and recognition, low training efficiency and accuracy, network degradation, etc., to improve the general capacity, reduced high requirements, effect of reduced number of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

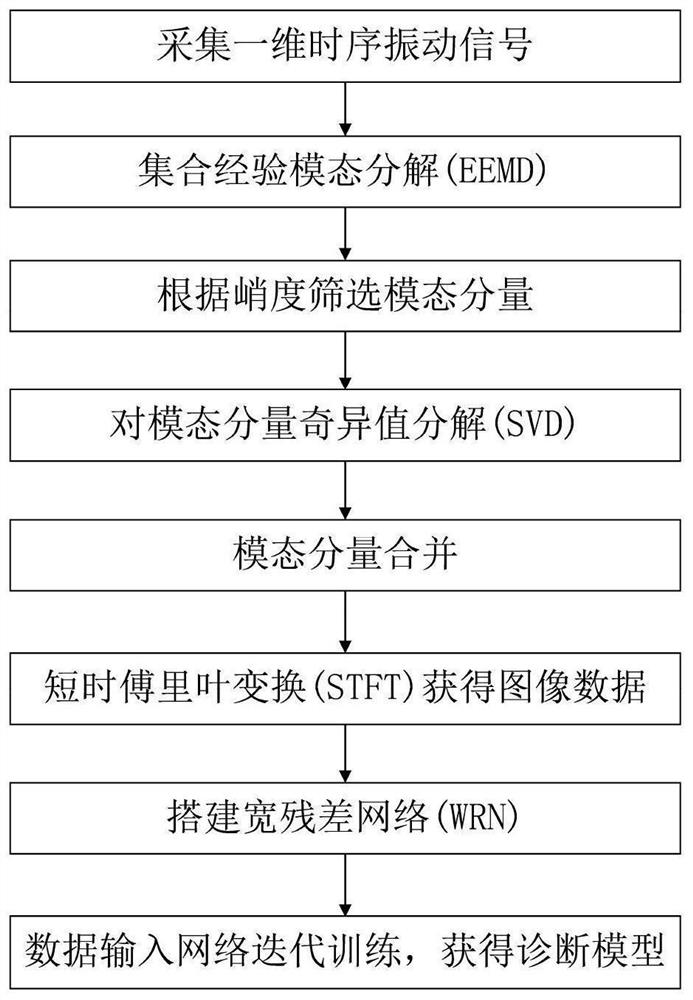

[0107] A spindle bearing fault detection method, the specific process is as follows:

[0108] Signal preprocessing: EEMD and SVD processing are performed on the collected one-dimensional time-series vibration signal. First, the vibration data is decomposed into multiple IMF components by collective empirical mode, according to the formula

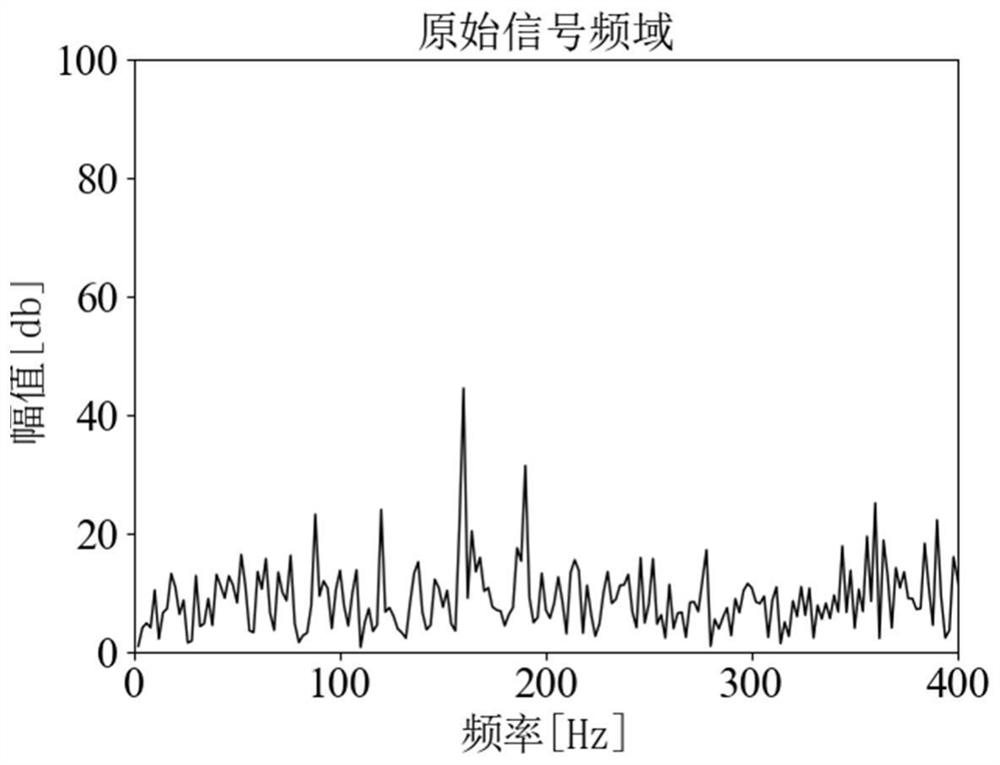

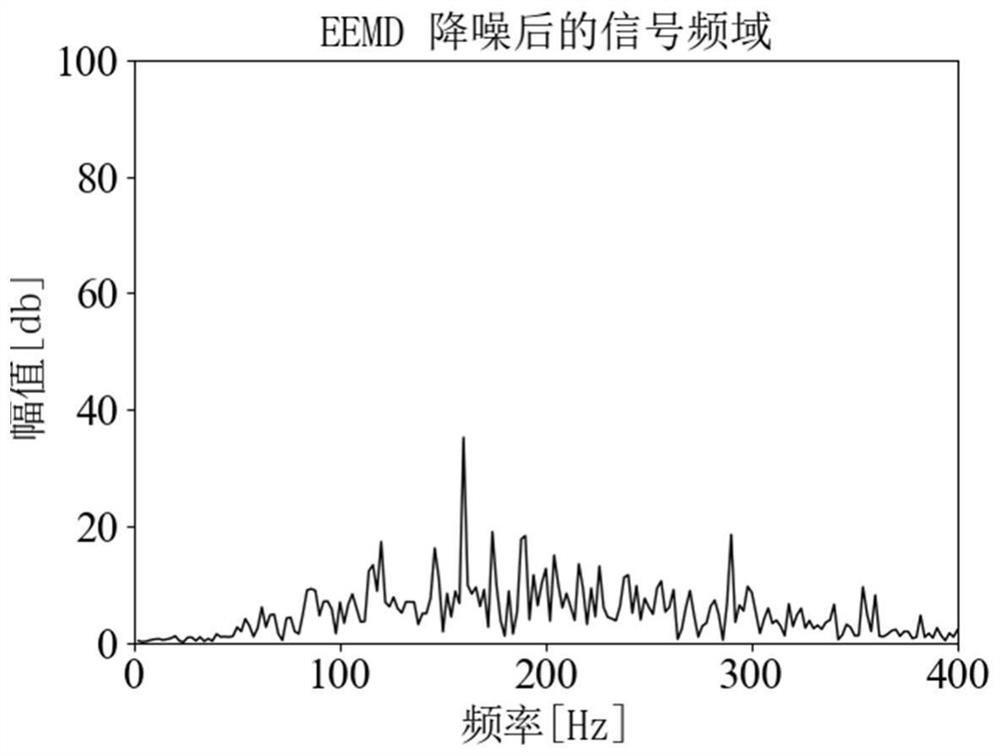

[0109] Calculate the kurtosis of each IMF component, and screen out the components with kurtosis greater than 0. In this example, the characteristic frequency of the inner ring fault is about 160Hz. Since there are still many noises in each IMF component, such as image 3 As shown, if the retained IMF components are directly combined, that is, only through EEMD processing, the noise reduction effect is still not ideal, so it is further optimized by SVD, and the intrinsic mode component IMF i =[a 1 ,a 2 ,a 3 ,...,a n ] Construct Hankel matrix Then carry out SVD decomposition H=UΣV T Get the singular value matrix Σ, keep the top 5 si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com