Battery thermal management system

A battery thermal management, battery technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

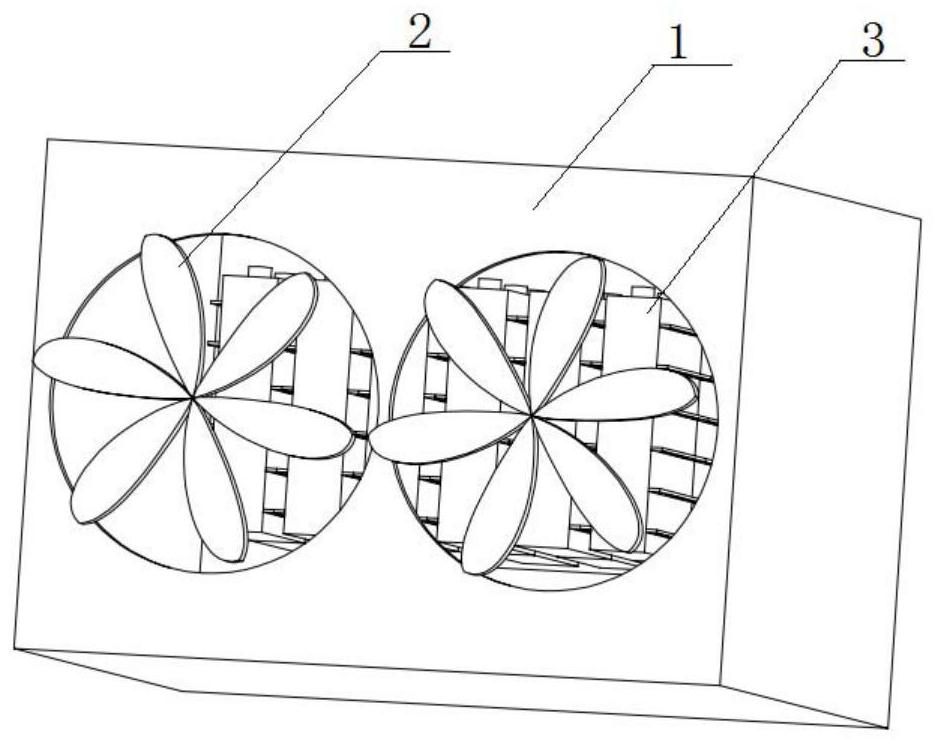

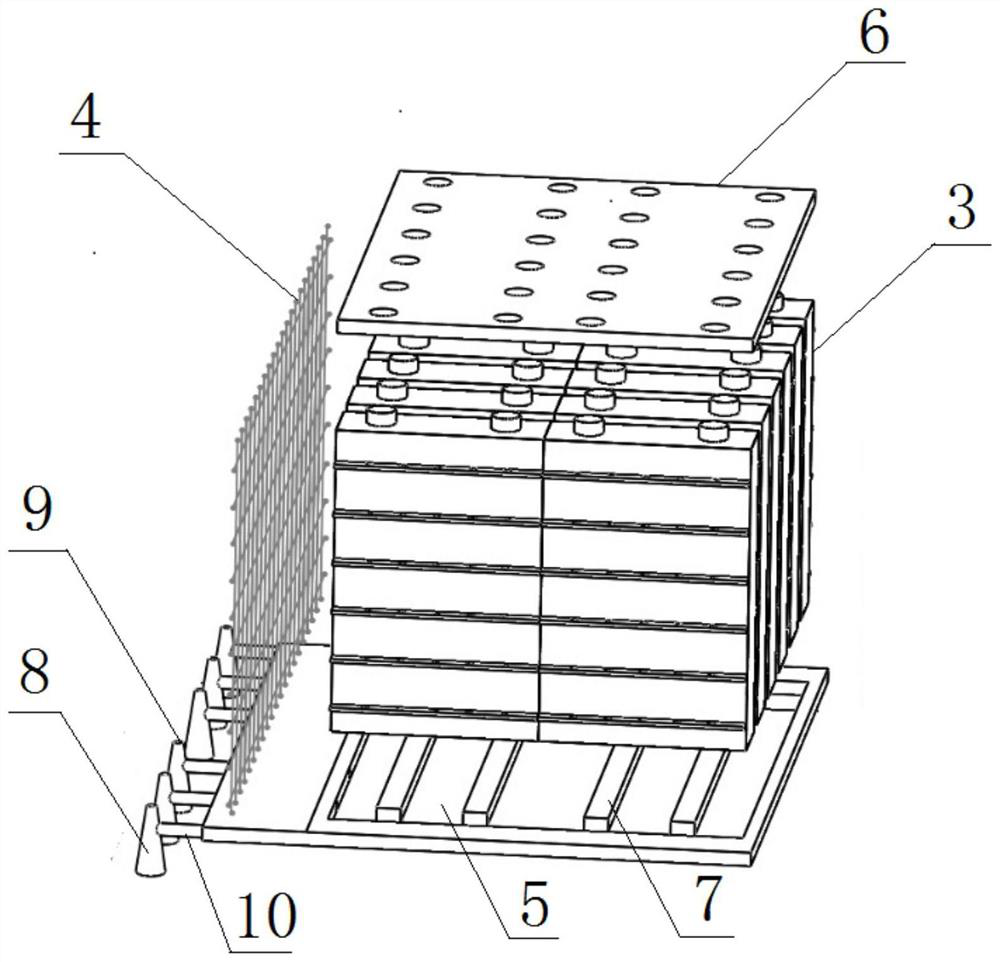

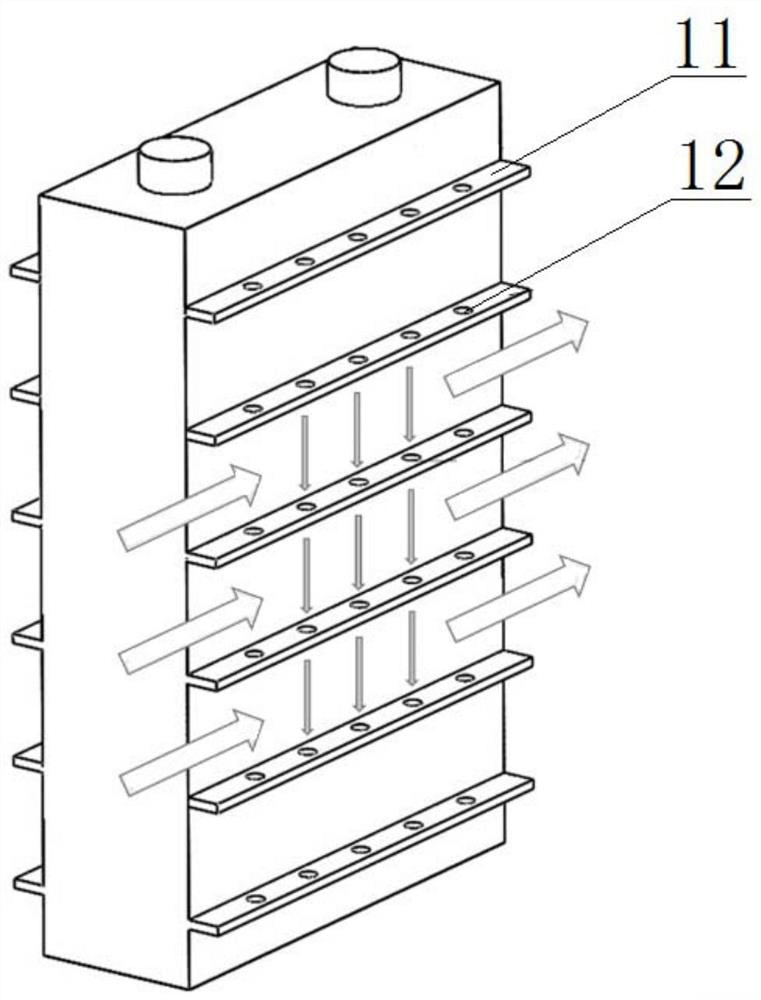

[0028] Such as Figure 1 to Figure 2 Shown is an embodiment of a battery thermal management system of the present invention. A battery thermal management system, which includes a battery case 1 and heat dissipation fins 11 arranged on the outer wall of the battery 3. The bottom of the battery case 1 is provided with a battery support, and the bottom of the battery support is provided with a condensation pool 5 , the condensation pool 5 is connected to the aerosol generator through a pipeline 10, the pipeline 10 is provided with a pressure pump that extracts the water in the condensation pool 5 to the aerosol generator, and the battery box 1 is provided with a temperature detection device for detecting the temperature of the battery 3 Module, the wall of the battery box 1 is provided with a fan 2, the electric heating wire mesh 4 is arranged between the battery 3 and the fan 2 in the battery box 1, and the nozzle 9 of the aerosol generator is arranged between the fan 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com