3D printing concrete color spraying system and application method

A 3D printing and concrete technology, applied in the field of 3D printing, can solve the problems of easy pollution of printing nozzles, waste of pigments, and mutual pollution of printed color materials, and achieve the effects of reducing costs, saving pigments, improving color adjustment accuracy and color printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

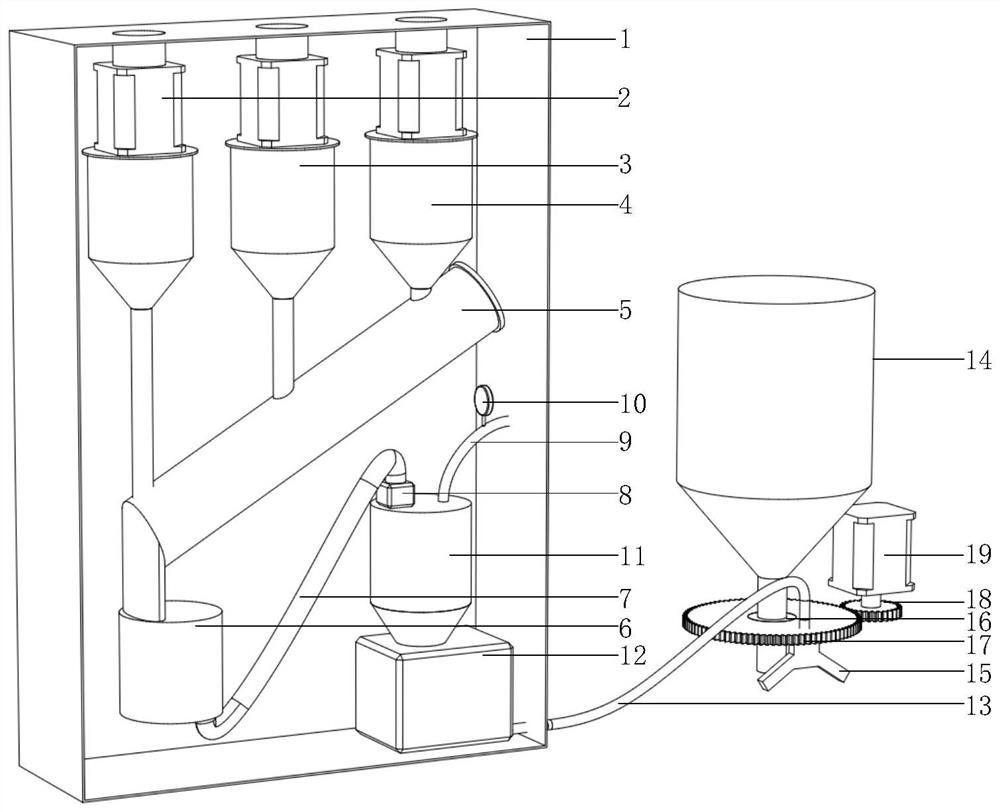

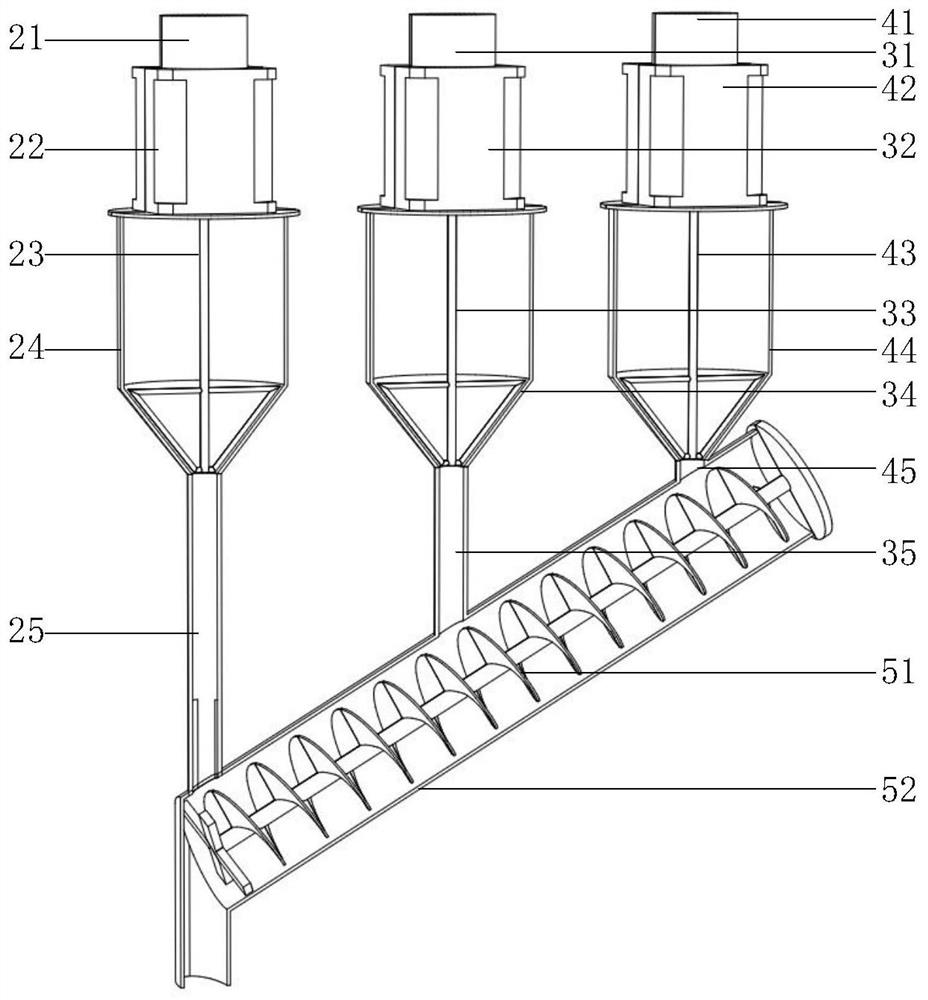

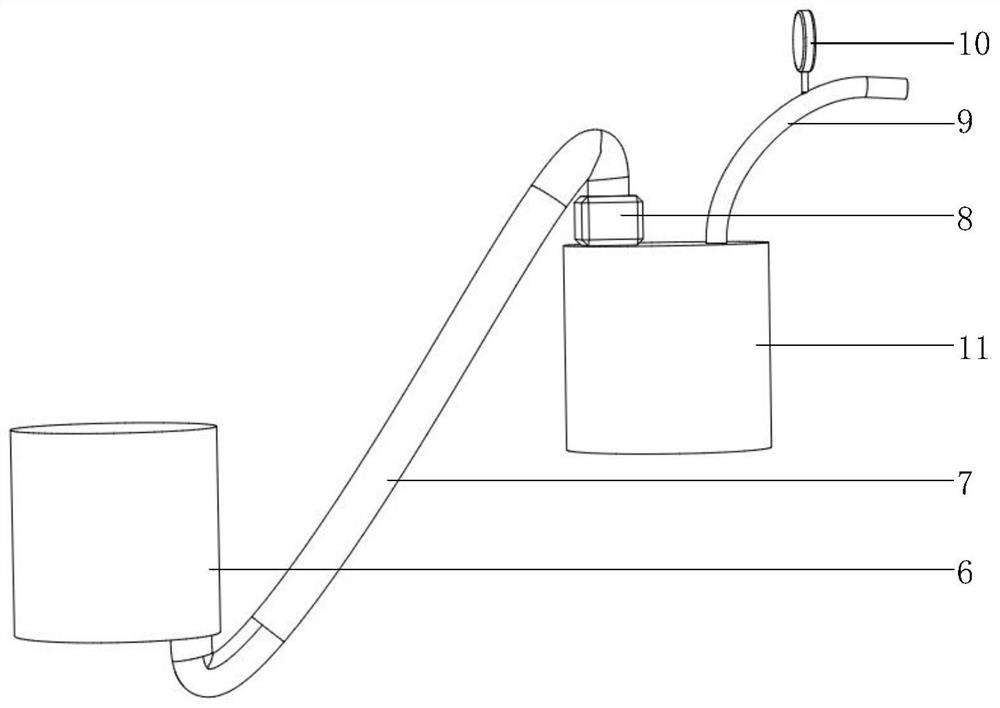

[0044] Such as Figure 1 to Figure 4 As shown, the 3D printing concrete color spraying system of the present invention includes a batching box 1, a batching module, a mixing module and a spraying module.

[0045] The batching module includes a first paint bin 2 , a second paint bin 3 , a dry powder mortar bin 4 and a material guide cylinder 5 .

[0046] The first paint bin 2 comprises a first gravity sensor 21, a first motor 22, a first stirring rod 23, a first paint bin 24, and a first delivery channel 25, and the first gravity sensor 21 is installed on the batching box 1 top, and The first motor 22 is connected, and the first gravity sensor 21 transmits the obtained weight information to the control system in real time. The first motor 22 is installed on the top of the first material bin 24, and the bottom is connected with the first agitating rod 23 to drive the first agitating rod 23 to rotate, and the switch and the rotating speed are controlled by the control system. T...

Embodiment 2

[0053] Please continue to refer Figure 1 to Figure 4 , This embodiment provides a method for using a 3D printed concrete color spraying system, using the 3D printed concrete color spraying system in Embodiment 1. In this embodiment, according to the mixing ratio of pigment a: pigment b: dry powder mortar: water = 2:2:100:25 (mass ratio), 1L of spray paint is prepared to spray the printed strips, and the density of the color mortar spray paint is 2kg / L. The method includes the following steps:

[0054] Step 1: Load pigment a into the first paint bin 2, load pigment b into the second paint bin 3, load dry powder mortar into the dry powder mortar bin 4, the first gravity sensor 21, the second gravity sensor 31 and the second gravity sensor The three gravity sensors 41 respectively transmit the weight information of the first paint bin 2, the second paint bin 3 and the dry powder mortar bin 4 to the control system in real time.

[0055] The control system opens the throttle val...

Embodiment 3

[0062] Please continue to refer Figure 1 to Figure 4 , this embodiment provides another method of using the 3D printed concrete color spraying system. The main implementation manner is the same as that of the second embodiment, the main difference lies in the manner in which the paint nozzle 15 rotates along with the printing path. The passive gear has 17 teeth and 100 teeth, and the transmission gear has 18 teeth and has 25 teeth. Other parameters are the same. The rotation direction of the printing path is clockwise, and the rotation angle is 90°. That is, the control system controls the motor 19 to rotate counterclockwise for one circle, the transmission gear 18 rotates 360° counterclockwise with the motor 19, and the driven gear 17 rotates 90° clockwise under the drive of the transmission gear 18, and the paint nozzle 15 rotates clockwise with the driven gear 17. Turn 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com