A kind of raw material composition, epe pearl cotton material and preparation method thereof

A technology of raw material composition and pearl cotton, which is applied in the field of packaging materials, can solve the problems of cell shrinkage and shrinkage of EPE pearl cotton materials, so as to ensure the safety of transportation and use, good product performance, and eliminate burning and the effect of explosion risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] The talc powder in Example 2 was purchased from Shanghai Titan Technology Co., Ltd. with a specification of 800 mesh.

[0044] In embodiment and comparative example, the N that adopts 2 The fixed amount is 0.008g / g LDPE, and this N can be adjusted arbitrarily in actual production 2 fixed amount, then CO 2 According to N 2 The amount of addition can be according to a certain ratio.

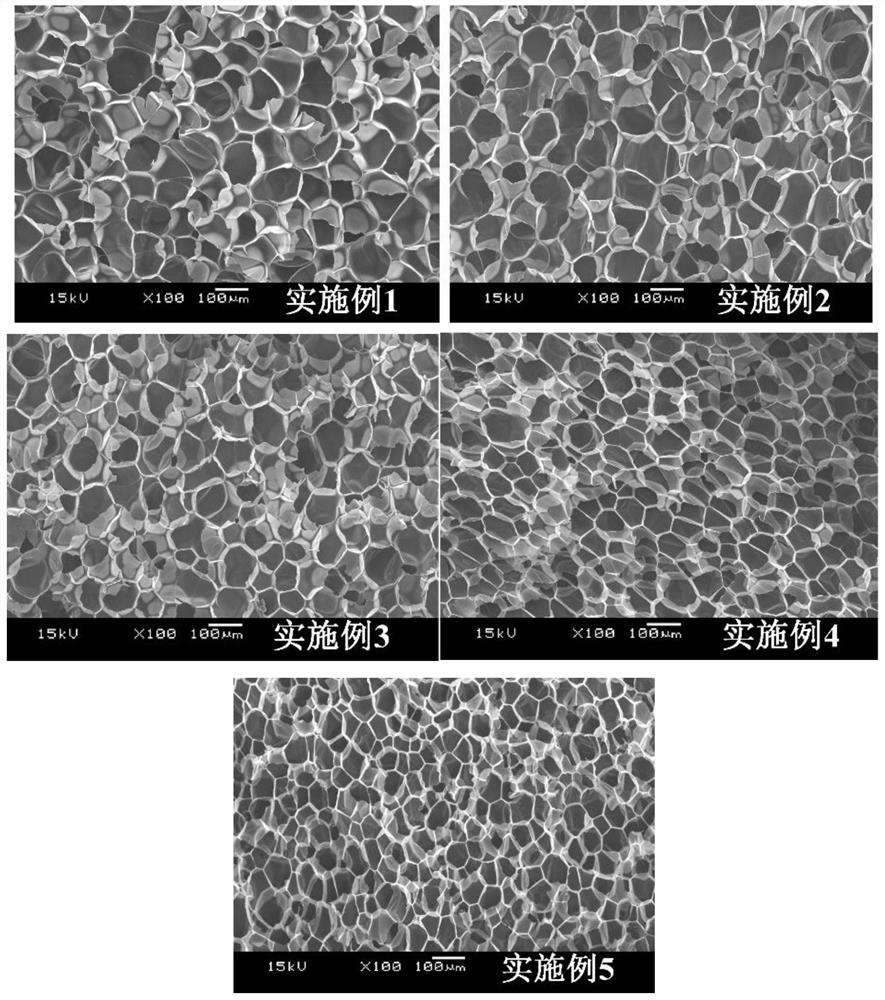

Embodiment 1

[0046] A kind of EPE pearl cotton material, by weight, it comprises following component:

[0047] 100 parts of LDPE resin pellets, 1.5 parts of mixed foaming agent; wherein, the mixed foaming agent is 0.7 parts of carbon dioxide and 0.8 parts of nitrogen, and the weight of nitrogen accounts for 55% of the total weight of the mixed foaming agent.

[0048] It is prepared by the following method:

[0049] Heat the extrusion foaming machine to heat up; add LDPE pellets, talc powder and mixed foaming agent to the extrusion foaming machine, and after mixing thoroughly, extrude through the die, cool, shape, flatten, pull, and coil That's it. In this example, N 2 The fixed addition amount is 0.008g / g LDPE; CO 2 The added amount is 0.007g / g LDPE.

[0050] Example 2

[0051] A kind of EPE pearl cotton material, by weight, it comprises following component:

[0052] 100 parts of LDPE resin pellets, 0.7 parts of talcum powder, and 2.2 parts of mixed foaming agent; wherein, the mixed ...

Embodiment 3

[0057] A kind of EPE pearl cotton material, by weight, it comprises following component:

[0058] 100 parts of LDPE resin pellets, 2.8 parts of mixed blowing agent; wherein, the mixed blowing agent is 2 parts of carbon dioxide and 0.8 part of nitrogen, and the weight of nitrogen accounts for 29% of the total weight of the mixed blowing agent.

[0059] It is prepared by the following method:

[0060] Heat the extrusion foaming machine to heat up; add LDPE pellets, talc powder and mixed foaming agent to the extrusion foaming machine, and after mixing thoroughly, extrude through the die, cool, shape, flatten, pull, and coil That's it. In this example, N 2 The fixed addition amount is 0.008g / g LDPE; CO 2 The added amount is 0.020g / g LDPE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com