A kind of preparation method of surfactant composite adhesive film

A surfactant and composite adhesive technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of affecting the service life of the adhesive film, the loss of surfactants, etc., to reduce surface adsorption, The effect of preventing internal clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

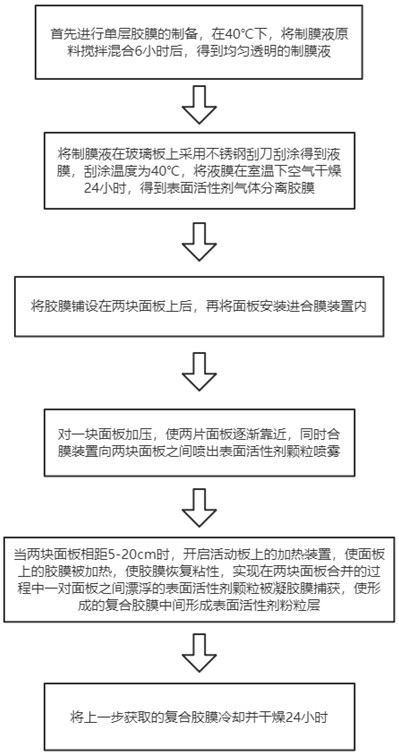

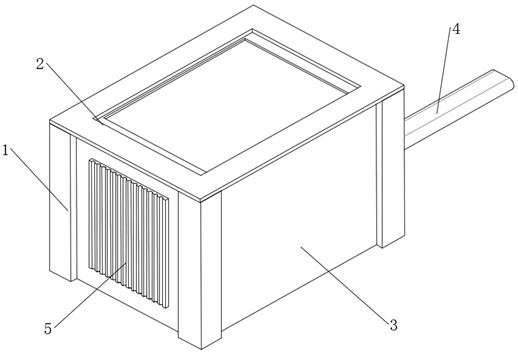

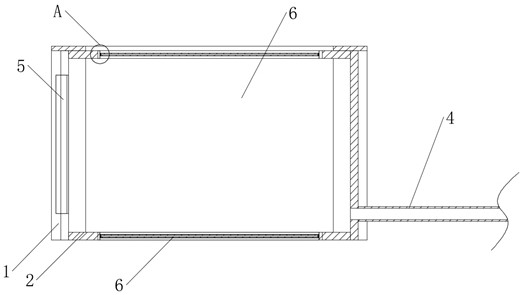

[0042] see Figure 1-4 , a preparation method of surfactant composite adhesive film, and its technological process is:

[0043] S1, firstly prepare a single-layer adhesive film. After stirring and mixing the raw materials of the film-forming liquid at 40°C for 6 hours, the rotating speed of the stirring device is 300 rad / min to obtain a uniform and transparent film-making liquid. The raw materials of the film-forming liquid are: 5 parts poly(ethylene-vinyl acetate), 5 parts polymethyl methacrylate, 10 parts Triton X-114 and 80 parts tetrahydrofuran;

[0044]S2, the film-forming liquid is scraped on a glass plate with a stainless steel scraper to obtain a liquid film, the scraping temperature is 40°C, and the liquid film is air-dried at room temperature for 24 hours to obtain a surfactant gas separation film, a gas separation film The thickness of the film is 100-300 μm, and the surfactant gas separation film can be screened for different gases. Hereinafter, the film refers to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com