Technological method for brewing white spirit by single-pit circulation method

A process method, the technology of circulation method, which is applied in the field of brewing liquor with single cellar circulation method, can solve the problems of less cellar opening, and achieve the effects of low intoxication, rich cellar aroma, and smooth taste of wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

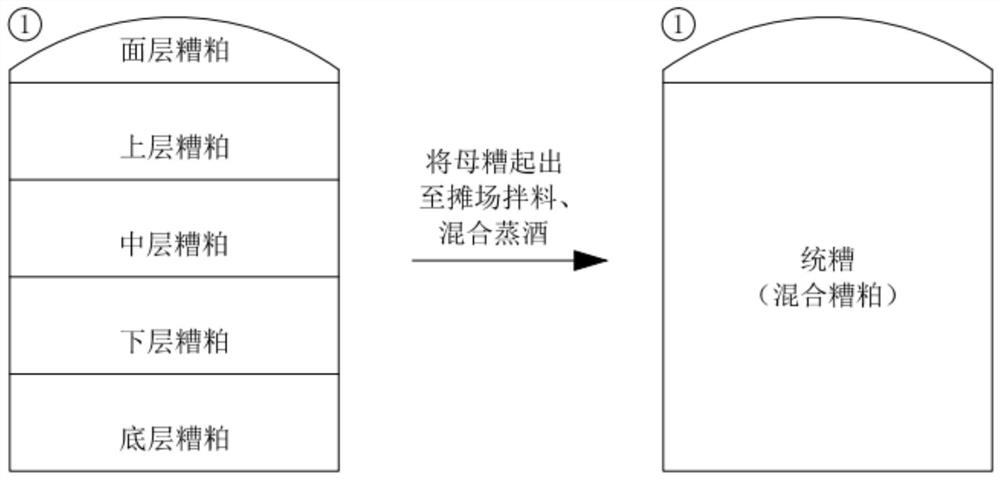

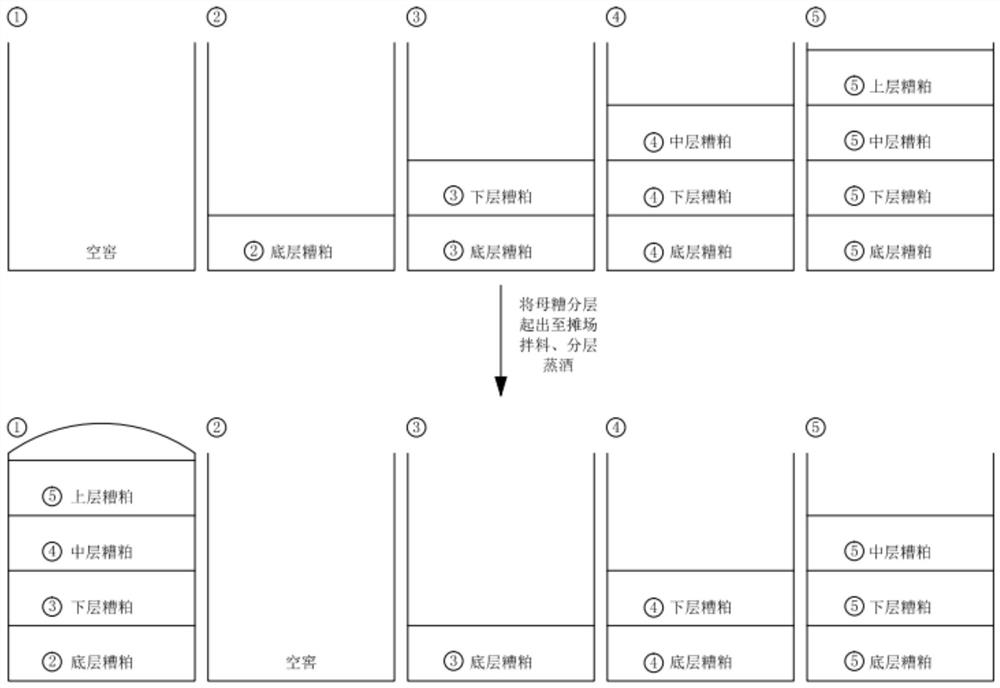

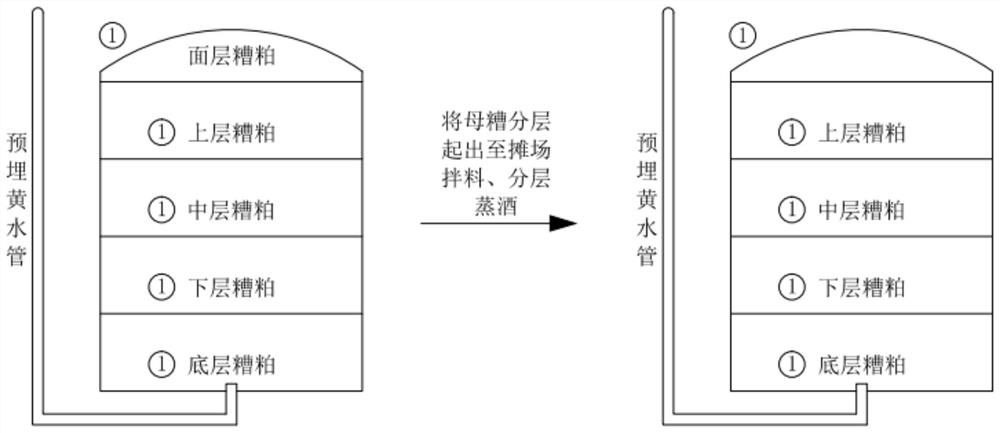

Method used

Image

Examples

Embodiment 1

[0032] A kind of technical method of single cellar circulation method brewing liquor, comprises the steps:

[0033] S1: Processing of raw materials and auxiliary materials: weighing sorghum single-grain wine body raw materials, multi-grain wine body raw materials and auxiliary materials according to the ratio, the single-grain wine body raw materials are sorghum, and the multi-grain wine body raw materials are: sorghum 20-40 %, glutinous rice 15-35%, rice: 15-35%, wheat 15-35%, peas 5-25%, the auxiliary material is chaff;

[0034] Single-grain wine-body raw materials: Finely crush the single-grain wine-body raw materials that have been weighed. The crushed single-grain wine-body raw materials have a crushing particle size of 4-8 petals. Soak for 18-20 hours, drain the water, cook in a pot for 20-30 minutes, take it out of the pot and let it cool, then add hot water at 85-90°C to moisten the ingredients;

[0035] Multi-grain wine-body raw materials: Mix the weighed multi-grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com