Patents

Literature

41results about How to "Strong cellar aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of multi-grain strong aromatic Chinese spirits

ActiveCN101892139AFull of nutritionStrong cellar aromaAlcoholic beverage preparationNutrientFood processing

The invention belongs to a food processing industry, in particular to a process of multi-grain strong aromatic Chinese spirits. The multi-grain strong aromatic Chinese spirits is prepared from the following raw material grains by proportion: 55 parts by weight of broomcorn, 4.5 parts by weight of corns, 16 parts by weight of wheat, 20 parts by weight of rice and 4.5 parts by weight of barley malts. The process of the multi-grain strong aromatic Chinese spirits is a process for producing the multi-grain strong aromatic Chinese spirits in the north under the conditions of cold, windy and dry weathers, the produced strong aromatic Chinese spirits have rich nutrient, strong aroma, prominent ester and grain flavor, sweet taste in mouth, fullness and smoothness, mellow taste and long aftertaste, and the process can be widely generalized and applied in northern weather conditions.

Owner:辽宁三沟酒业有限责任公司

Strongly-aromatic white wine produced by using lake plants such as water caltrop, gordon euryale seed, lotus seed, and the like as raw materials and preparation method thereof

ActiveCN101544936AGreat tasteLong-lasting aftertasteAlcoholic beverage preparationSorghumAroma aroma

The invention relates to a strongly-aromatic white wine produced by using lake plants such as water caltrop, gordon euryale seed, lotus seed, and the like as raw materials and a preparation method thereof. The main materials and accessories used for producing the white wine include the following materials according to the parts by weight: 60-80 of sorghum, 20-30 of water caltrop, 4-10 of gordon euryale seed, 1-5 of lotus seeds, 2-3 of lotus leaf, 1-2 of lotus, 20-30 of rice husk, 20-30 of Daqu and 400-500 of well-fermented mature grains. The invention brings the characteristics of the raw materials into full play; the main materials and the accessories are well mixed; the use and the mixing proportion of the raw materials are proper; the brewed white wine is not bitter or spicy but strongly aromatic and delicious and is a strongly-aromatic white wine with the mixed aroma of grains and locus which have the characteristics of the lake plants; and the quality of the wine is stable and far better than the qualities of other strongly-aromatic white wines.

Owner:一品液酿酒(山东)有限公司

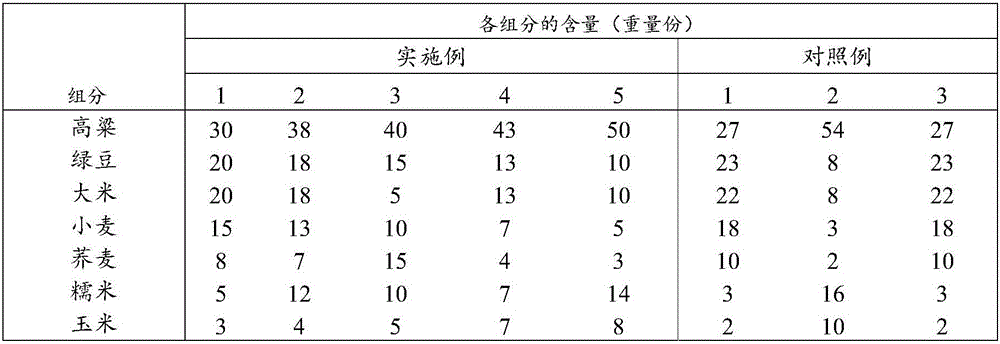

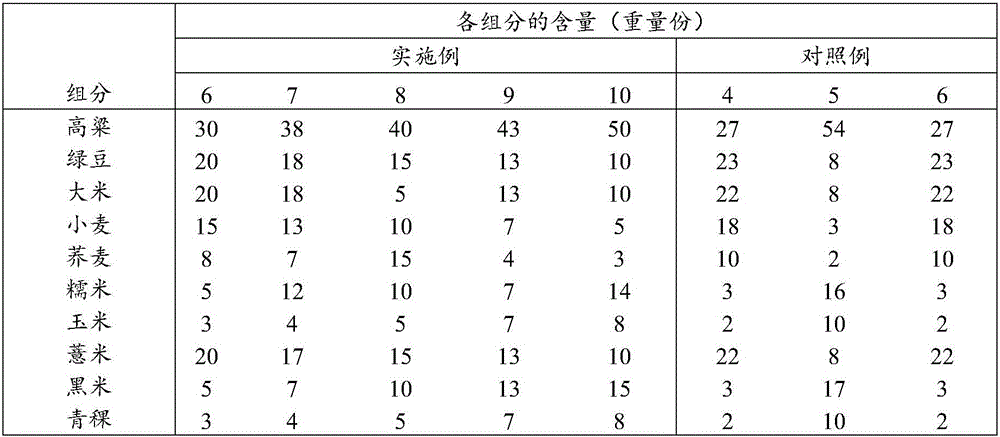

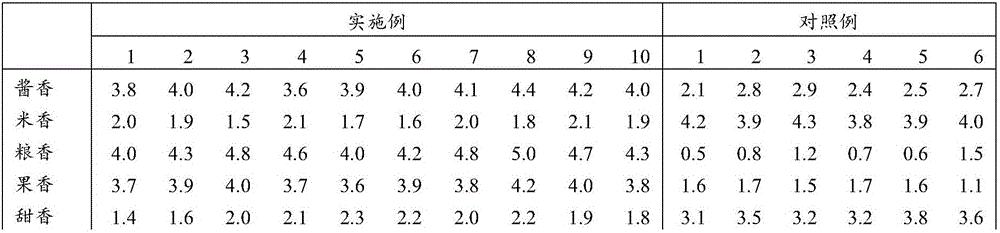

Brewing formula and brewing process of heavy-flavor baijiu

InactiveCN105820937AWith hypolipidemicCholesterol-loweringAlcoholic beverage preparationFlavorMaterials preparation

The invention provides a brewing formula and brewing process of heavy-flavor baijiu. The brewing formula comprises, by weight, 30-50 parts of sorghum, 10-20 parts of mung beans, 10-20 parts of rice, 5-15 parts of wheat, 3-8 parts of buckwheat, 5-14 parts of sticky rice and 3-8 parts of corn. The brewing process includes the steps of material preparation according to the formula, pretreatment for crushing, mixing and decocting raw materials, diastatic fermentation of steamed raw materials and distillation conducted on fermented grains and baijiu taking. The brewing process is simple, brewing time is short, all brewing parameters are easy to control, and operability is high. The brewed baijiu is heavy in fragrance, soft and sweet and coordinate in fragrance; after the baijiu is drunk, the stomach is not impaired, headache is not caused, and a drinker is not prone to drunkenness.

Owner:YIBIN HUIS WINE CO LTD

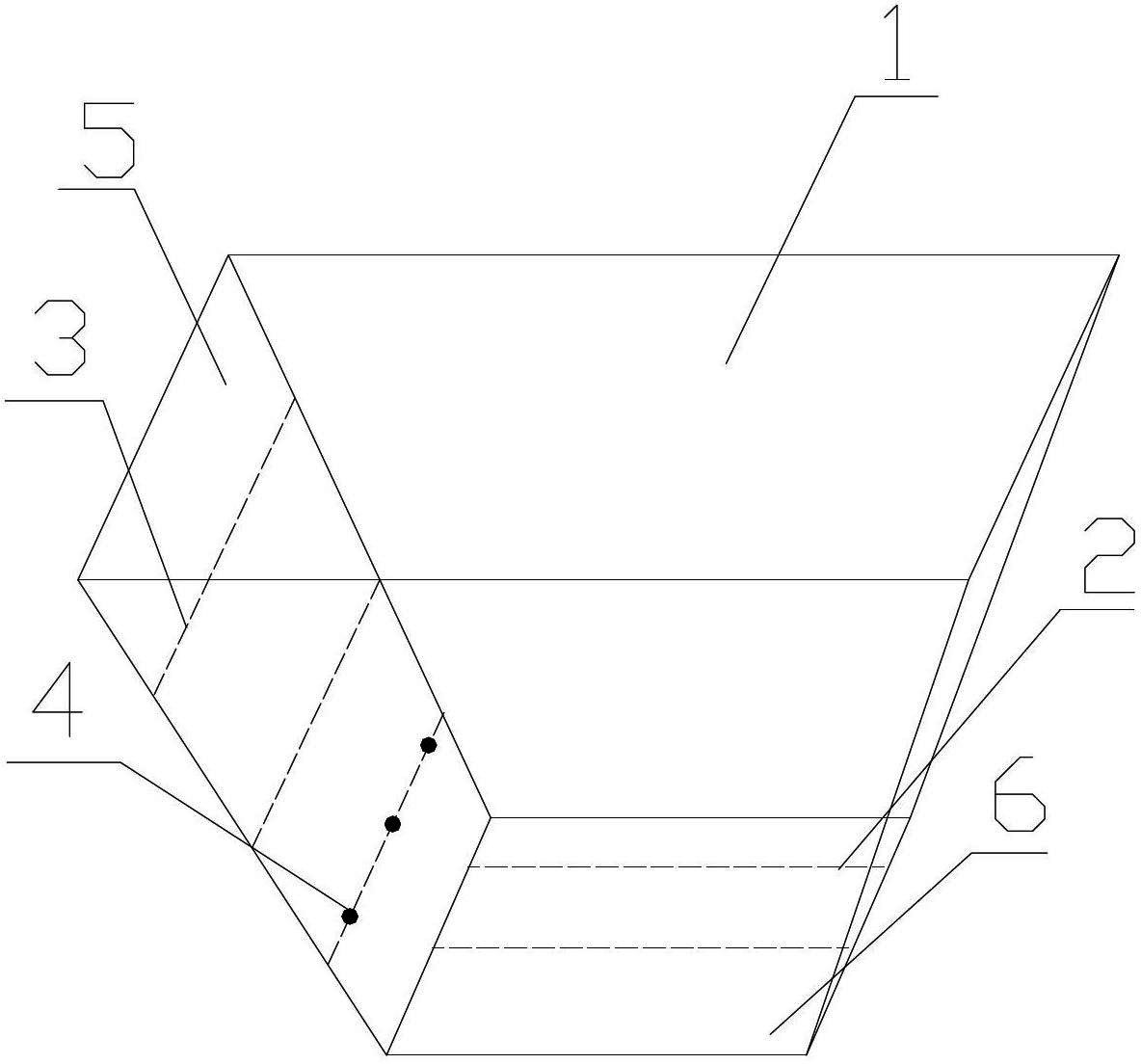

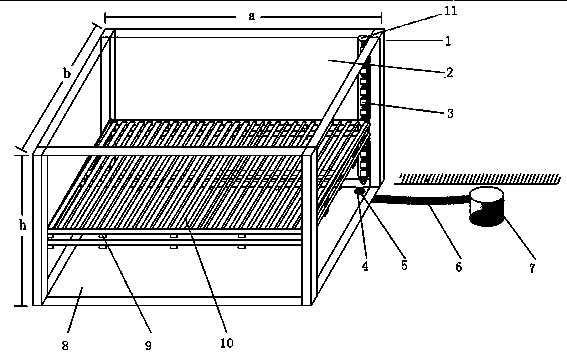

Protection method for strong flavor spirit cellar pit mud

ActiveCN102703277AAvoid contactAvoid damageAlcoholic beverage preparationHigh probabilityMechanical equipment

The invention relates to a protection method for strong flavor spirit cellar pit mud, belongs to the technical field of brewing and solves the technical problems of high probability of causing stripping of the cellar pit mud during grain removal of mechanical equipment, grabbing of the bottom pit mud and distilled grains, and foreign flavor, discordance and uncleanness of the wine distilled from the distilled grains. The technical scheme for solving the technical problems is the protection method for the strong flavor spirit cellar pit mud. The protection method comprises the following steps of: a, cleaning cellar wall and cellar bottom after the fermentation is finished and the grains are removed; b, placing bamboo strips at the cellar bottom and the cellar wall; and c, charging in the cellar, sealing the cellar and performing a next cycle of fermentation. According to the preparation method, contact of the grain removal equipment and the cellar bottom or the cellar wall can be avoided, the damage caused to the cellar pit and the cellar mud during grain removal is effectively prevented, and the stability of the brewing performance of the cellar pit and the quality of base liquor are improved.

Owner:LUZHOU PINCHUANG TECH CO LTD

Liquor and brewing process thereof

InactiveCN101302465AThe wine is clear and transparentStrong cellar aromaAlcoholic beverage preparationDistillationFood flavor

The invention relates to white spirit - Manchu cave storage wine which inherits and summarizes the prior brewing technique and the modern science technology and a brewing technique for the Manchu cave storage wine. The Manchu cave storage wine is prepared by the following raw materials by weight ratio: the weight ratio of sorghum to fermented grains to rice hulls to Daqu powder is 1 to 4.5-5.0 to 0.15-0.20 to 0.20 to 0.26. The brewing technique inherits and carries forward the unique white spirit brewing and storing techniques of Manchu, adopts luscious underground spring water, selects superior sorghum and minor cereals, takes intermediate and high temperature Daqu as saccharified ferment, and adopts the characteristics of the mixed multi-turn fermentation technique and the techniques such as fermentation in a mud fermentation pit, distillation in a stone pot, aged wine storage in a cave, elaborate blending and so on. The Manchu cave storage wine has limpid and transparent wine body, aromatic flavor of a fermentation pit, heavy wine body, coordinated flavors and clean taste, is pleasant after taste and has unique wind body style.

Owner:关健

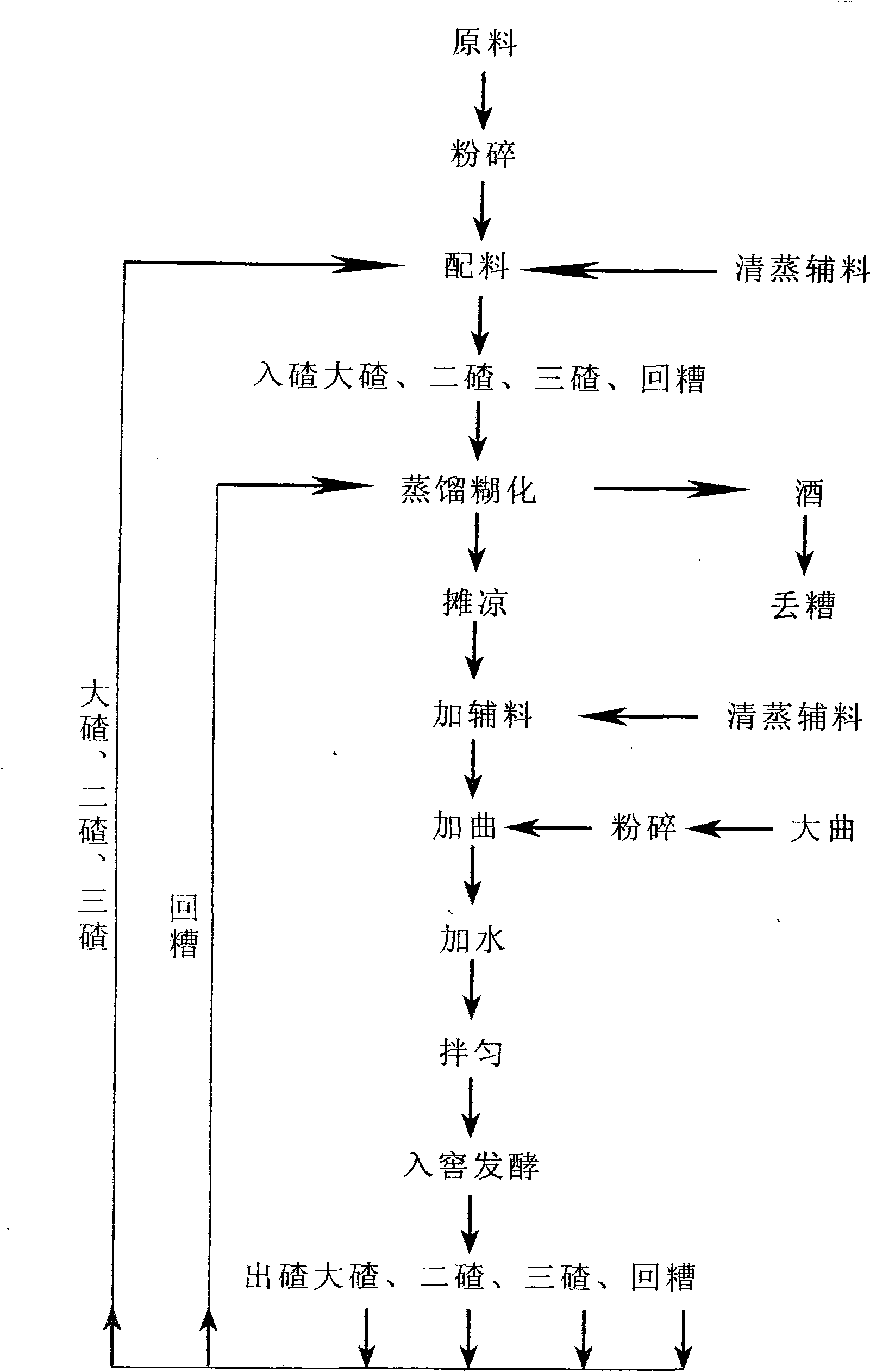

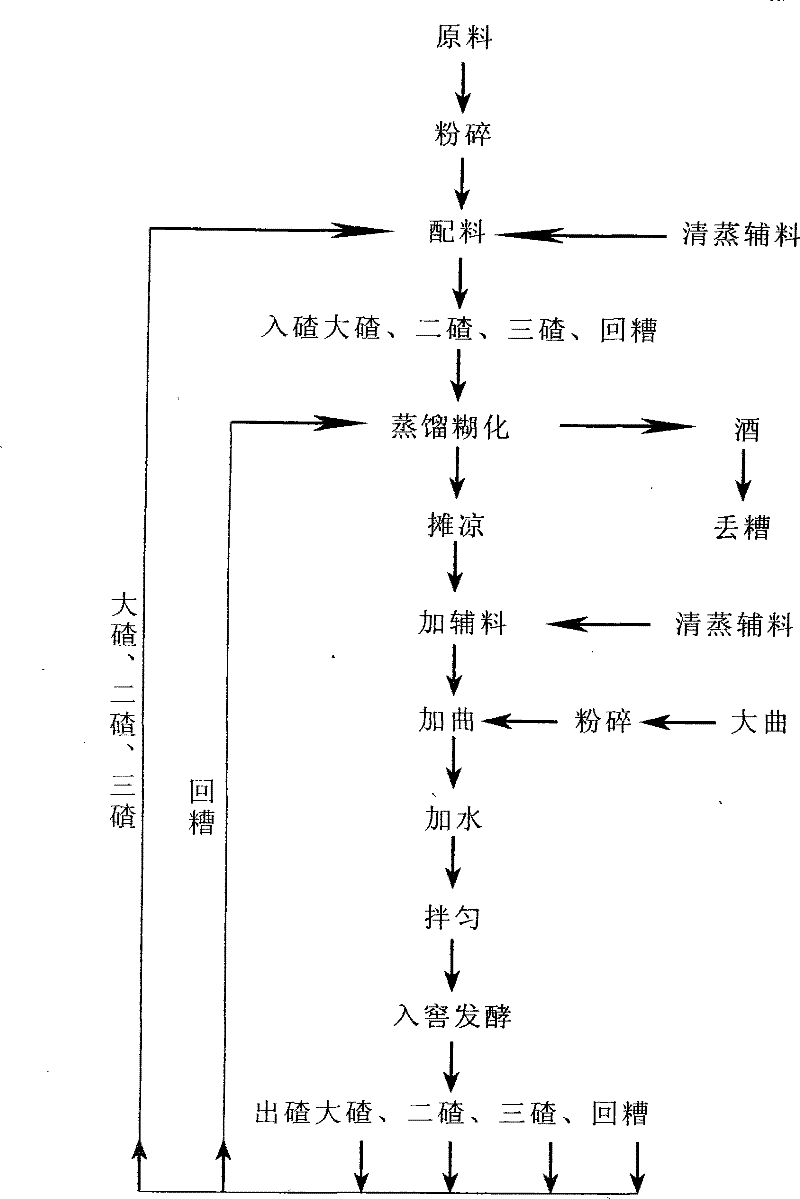

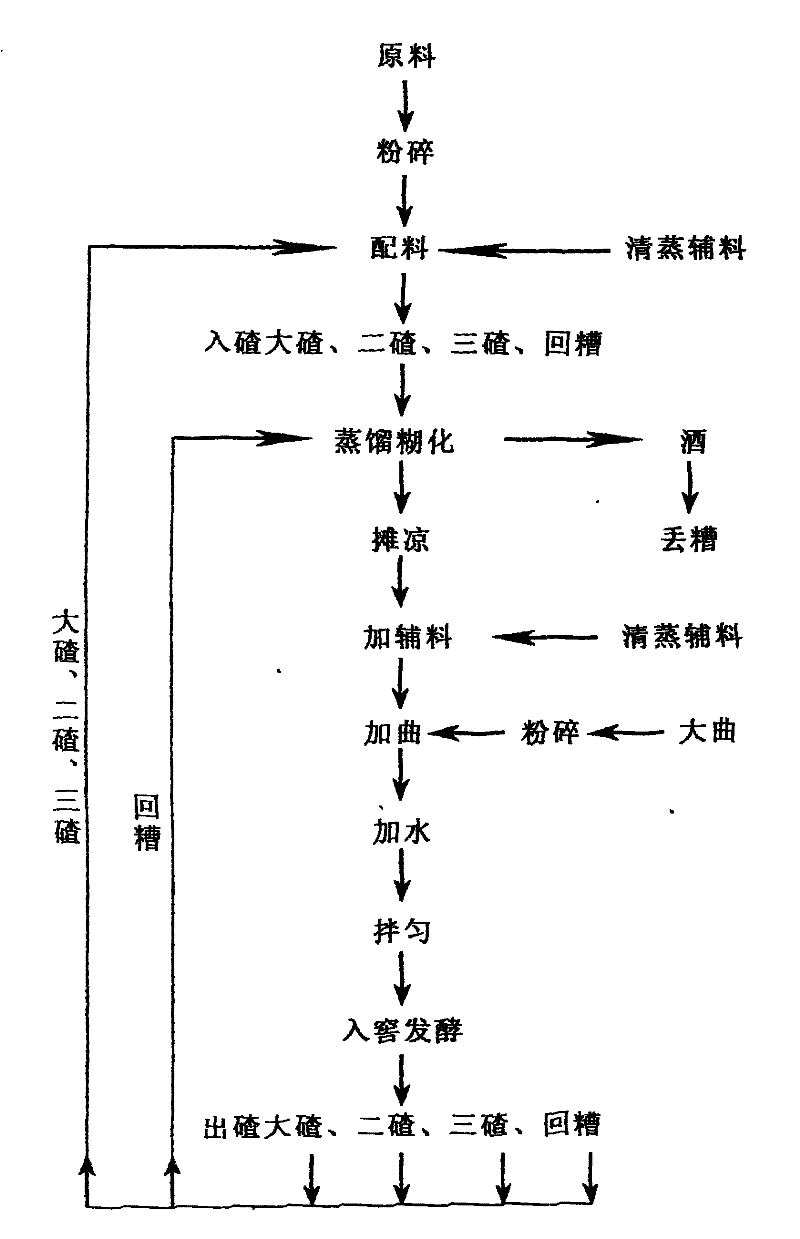

Brewing technology for strong aromatic Chinese spirits

The invention discloses a brewing technology for strong aromatic Chinese spirits. The brewing technology includes the following steps that a, main materials and auxiliary materials are selected, and the main materials are prepared in proportion; b, the auxiliary materials and the prepared main materials in the step a are added into fermented maternal draff in proportion, and cooking gelatinizationis carried out through three retorts; c, after cooking gelatinization is carried out, sufficient water watering, spreading cooling and distiller's yeast scattering are carried out, to-be-fermented materials are obtained, and the to-be-fermented materials are put into a fermenting tank and fermented; d, fermentation is expired, then the fermenting tank is opened, fermented grains in the fermentingtank are taken and used for steaming liquor, the liquor is steamed through four retorts, fermented grains obtained after steaming are used for the maternal draff in the step b and used for secondaryfermentation, steamed liquor is taken according to the quality, and raw liquor is obtained; e, the raw liquor obtained in the step d is stored through classification, after the stored raw liquor is aged and matured, blending and filtering are carried out, then storing, filling and lamp inspection are carried out, and then the strong aromatic Chinese spirits can be warehoused. The problems that anexisting Chinese-spirit brewing technology is complex, and the quality of the brewed Chinese spirits cannot be guaranteed are solved.

Owner:河南蔡洪坊酒业有限公司

Blending method of mixed-flavor type white spirit

InactiveCN105779208AUnique fragranceRich fragranceAlcoholic beverage preparationAlcohol contentAdditive ingredient

The invention discloses a blending method of mixed-flavor type white spirit. The blending method comprises the steps of base liquor selection, base liquor blending as well as alcohol content drop and packaging. The blended white spirit is unique in aroma, and the various aromatic substances are high in content, diversified in type, and rich in aroma. The white spirit blended according to the method has the advantages that the wine body is mellow and rich, has lingering aftertaste, strong pit aroma, soft sweet and refreshing mouthfeel, and pure faint scent, and has harmonious flavors, refreshing and clear aftertaste, and fresh honey fragrance; a drinker obtains soft continuous mouthfeel after the white spirit just enters the mouth, and obtains the refreshing and clear mouthfeel after swallowing the white spirit, and the aftertaste is enjoyable and smooth. According to the blending method, the different micro ingredients with different aroma types are blended with the base liquor, and then the new balance is achieved, so that the wine body has good harmony and unity.

Owner:遵义市董程窖酒厂

Complex enzyme special for white spirit

InactiveCN101481682AHigh activityHydrolysis function appearsHydrolasesAlcoholic beverage preparationPectinaseFood flavor

The invention discloses a composite enzyme special for distilled spirit, which consists of cellulose, hemicellulose, beta-dextranase, diastatic enzyme, pectinase and protease. The composite enzyme special for distilled spirit has synergetic effect, and can effectively transform components such as starch, fat, protein and the like in raw materials and promote fermentation; while keeping fragrance of the distilled spirit in the fermentation process, greatly increase fragrant component content, speeds up reaction balance between alcohols, aldehydes, acids and esters, improves quality of distilled spirit, shortens fermentation period and shortens storage time. Production practices show that the composite enzyme special for distilled spirit which is used for fermenting distilled spirit improves yield and quality of distilled spirit without influencing flavor of primary wine. The composite enzyme special for distilled spirit can be applied to various distilled spirit production techniques with different conditions.

Owner:天津科建科技发展有限公司

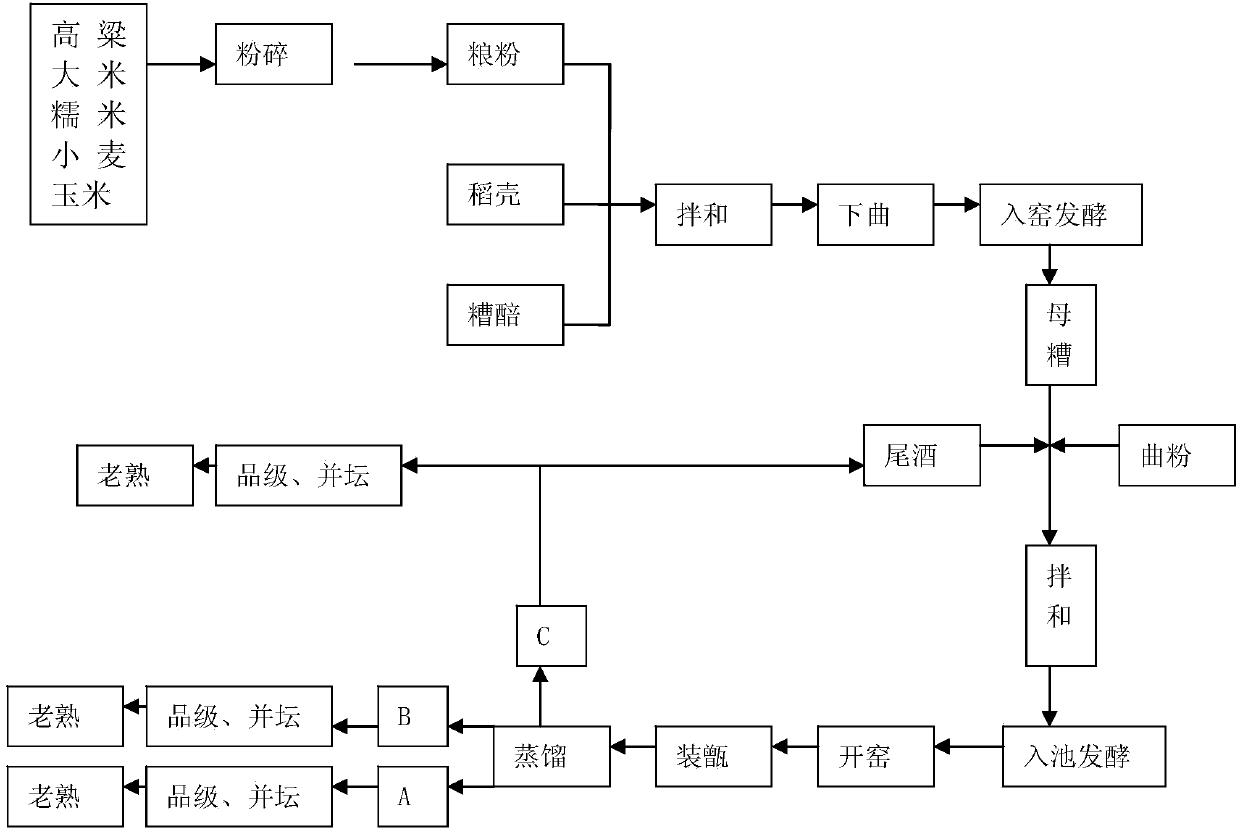

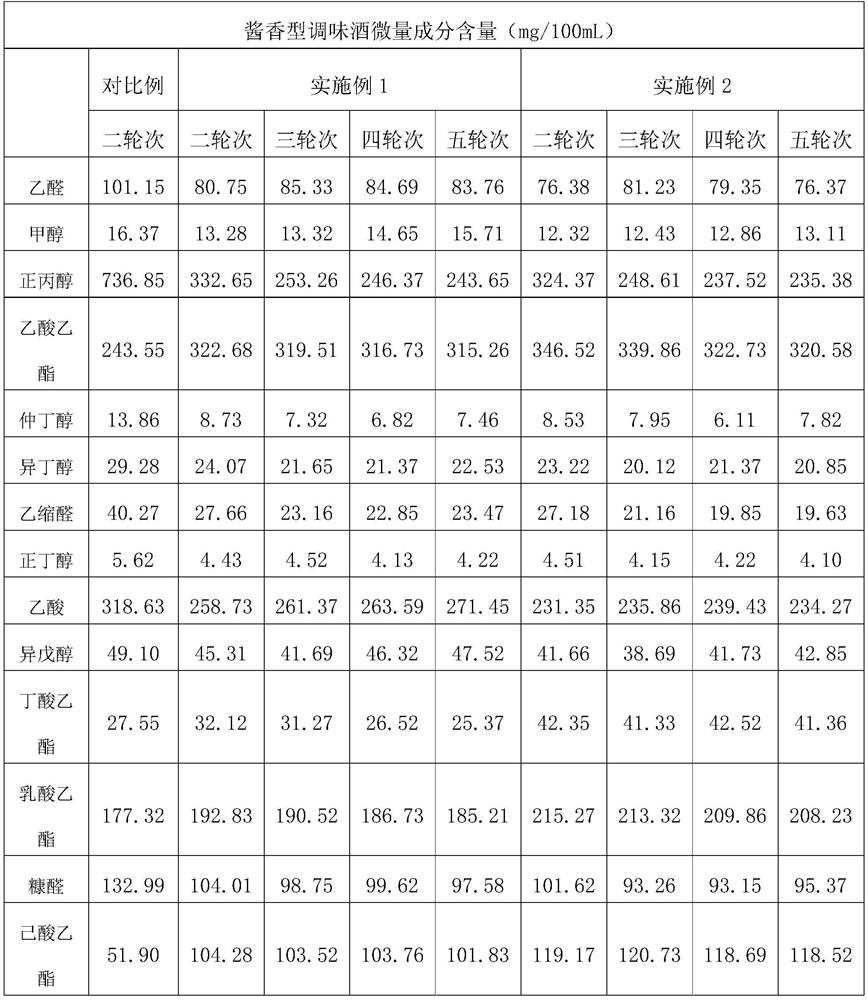

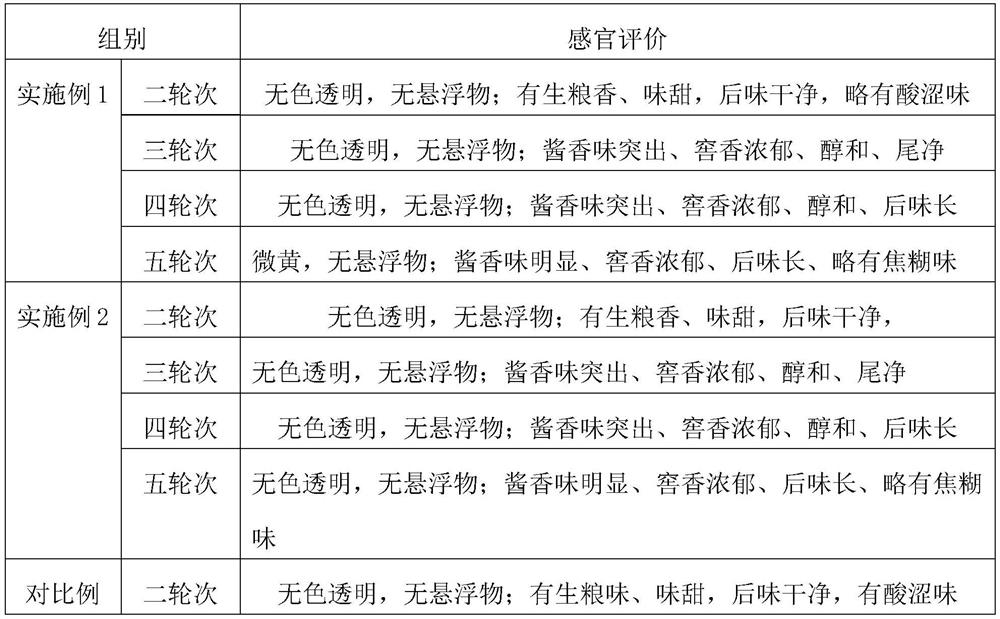

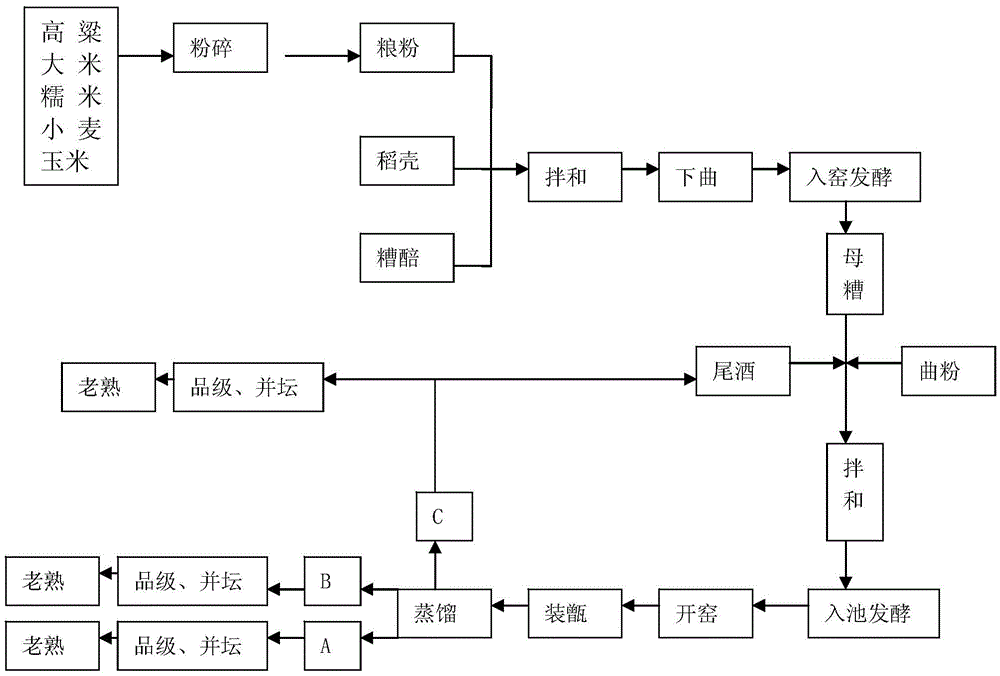

Production process of high-quality strong-flavor type seasoning wine

The invention discloses a production process of high-quality strong-flavor type seasoning wine, which belongs to the field of wine production. Each production period of the process comprises two fermentation rounds, the first round comprises procedures of crushing raw materials, steaming to sterilize, feeding into a pond at low temperature, cooling down, adding yeast and feeding into a kiln for fermentation; the second round comprises procedures of discharging from the kiln, stirring tail wine, cooling down, adding yeast, feeding into a pond for fermentation and the like. According to the production process, through steps of distilling in gentle fire and taking the wine in different sections, the tail wine part is added into the second round of blending step, and the operation is circulated so as to obtain the strong-flavor seasoning wine of different grades. According to the production process, five grains, namely, sorghum, rice, sticky rice, wheat and corn, are taken as raw materials, high / medium yeast is used as a saccharifying fermentation agent, the raw materials are fed into the pond at low temperature, a unique sand-casting process is adopted for slowly fermenting in two rounds, the content of alcohol substances in the seasoning wine is increased, and strong pit flavor is achieved.

Owner:QINGDAO LANGYATAI GRP

Process method for increasing high-quality baijiu rate of strong aromatic baijiu brewing production

InactiveCN108624461AImprove the cultivation effectExtended fermentation periodAlcoholic beverage preparationYeastDistillation

The invention discloses a process method for increasing a high-quality baijiu rate of strong aromatic baijiu brewing production and relates to the field of baijiu brewing. The process method comprisesthe following steps: preparing fermented grains, and preserving double bottom-fermented mashes of a former round; adding distiller's yeast, replenishing water, piling to culture bacteria, and preparing flavoring fermented grains; carrying out interlayer grain refluxing, forming cross ridges at the bottom of a pool, and sealing the pool to carry out fermentation; prolonging a fermentation period,taking up distillers' grains layer by layer, maintaining a fermentation pit, and retaining the double bottom-fermented mashes of the round in the fermentation pit; carrying out grain circulation distillation, and preparing fermented grains of a next round; placing the double bottom-fermented mashes of the former round at a steamer opening, carrying out distillation, and harvesting baijiu of different types; storing baijiu respectively, aging for a long time, and blending for use. By adopting the process method, process details of pit sealing, cover amounts of surface distillers' grains and pitend mud, and the like, are intensified. The process method disclosed by the invention is adopted to brew strong aromatic baijiu, and compared with a conventional strong aromatic baijiu brewing process, the process method has the advantages that the high-quality baijiu rate is increased, baijiu is mellow and full, thick and graceful in pit fragrance and long lasting and fine in aftertaste, and thepursuit of customers on high-quality strong aromatic baijiu can be met.

Owner:ANHUI GOLDEN SEED WINERY CO LTD

Tea-flavored white wine brewed by solid state fermentation and brewing process

InactiveCN102311899ATea fragrance is obviousStrong cellar aromaAlcoholic beverage preparationChemistryTea leaf

The invention relates to a colourless tea-flavored white wine and a brewing process thereof. The brewing process comprises primary pure grain solid state fermentation, primary tea leaf mixing, primary distillation and wine roasting, primary ageing, filtering and blending.

Owner:骆明

Pure grain brewing fruity-type spirit and preparation method thereof

InactiveCN109082352ALong aftertasteClean aftertasteAlcoholic beverage preparationPolygonum fagopyrumTriticum turgidum

The invention provides pure grain brewing fruity-type spirit and a preparation method thereof. The pure grain brewing fruity-type spirit is prepared by the following raw materials in parts by weight:20-30 parts of mung bean, 10-20 parts of myotonin, 10-15 parts of potatoes, 30-60 parts of sorghum, 20-40 parts of wheat, 20-40 parts of rice, 20-30 parts of millet, 20-40 parts of glutinous rice, 10-20 parts of small red beans, 10-30 parts of yellow rice, 10-20 parts of black rice, 0-10 parts of white kidney beans, 0-10 parts of pinto beans, 0-10 parts of peanuts, 0-10 parts of black soya beans,0-5 parts of semen sesami nigrum, 20-30 parts of buckwheat, 10-20 parts of soybeans and 20-50 parts of corn. A product of the pure grain brewing fruity-type spirit keeps strong cellar fragrance, and is lasting in aftertaste. Sweet, soft and fresh aftertaste feeling is increased for the fruity-type spirit, so the fruity-type spirit is more abundant in mouthfeel, and popular with more consumers.

Owner:前郭尔罗斯蒙古族自治县十粮酒业有限公司

Strong-flavor type Baijiu and blending and producing process thereof

PendingCN109749913AIncrease the content of aromatic substancesReduce lossesAlcoholic beverage preparationAcetic acidAlcohol

The invention discloses strong-flavor type Baijiu. The Baijiu is prepared by blending wine base including, by mass, 50-60% of edible alcohol, 15-25% of strong-flavor top-grade liquor, 15-25% of strong-flavor first-grade liquor, 1-2% of tail alcohol, 0.01-0.05% of strong-flavor double-round liquor, 1-3% of five-grain flavor liquor, 0.3-0.6% of a natural sweetener, 0.2-0.3% of acetal, 1-2% of ethylcaproate, 0.5-1% of ethyl acetate, 1-1.5% of ethyl lactate, 0.2-0.3% of ethyl butyrate, 0.2-0.3% of caproic acid, 0.05-0.1% of acetic acid, 0.1-0.3% of lactic acid, 0.1-0.2% of butyric acid and 0.1-0.3% of acetaldehyde. By means of the strong-flavor type Baijiu and the blending and producing process thereof, the loss of liquor body flavor substances can be effectively reduced, a liquor body can better keep the original style and typicality, and the product quality is improved.

Owner:江西省宜丰洞山酒业有限公司

Solid state fermented peony wine and preparation process thereof

InactiveCN109370834AEffective dispersionImprove effectivenessDigestive systemAlcoholic beverage preparationFood additiveBULK ACTIVE INGREDIENT

The invention provides solid state fermented peony wine and a preparation process thereof. The peony wine is prepared by fermenting to brew fermented grains by taking rice, sorghum, wheat, peas, corns, ginseng, fructus ziziphi jujubae and medlar as raw materials; distilling the obtained fermented grains; taking wine tailings; adding peony into the wine tailings; extracting; performing secondary fermenting on the extracted mixture and distilling to obtain finished peony wine. According to the process for preparing the peony wine provided by the invention, respective advantages of a fermenting process and an extracting process are absorbed; the peony is extracted by adopting the wine tailings obtained by distilling the fermented grains, so that the peony is effectively dispersed and fermenting is benefited; meanwhile, nutrient elements, such as vitamins and minerals, in the wine tailings are remained; in addition, active ingredients and aroma in the peony are fully extracted by the winetailings; the extracted mixture is subjected to secondary fermenting, so that active ingredients in the peony are further separated out, and the active ingredients and the aroma in the peony in the finished peony wine are improved; moreover, food additives are not required to be added, and the requirements of modern customers on natural and additive-free food are met.

Owner:虞城县瑾永美贸易有限公司

Brewing method of Maotai-flavor flavored liquors

ActiveCN113604306AColorless and transparentStrong cellar aromaAlcoholic beverage preparationWine cellarEngineering

The invention discloses a brewing method of Maotai-flavor flavored liquors and belongs to the technical field of Maotai-flavor liquor brewing. The brewing method comprises the following steps: 1, preparing auxiliary materials: a, maternal grains; b, a high-temperature yeast for making hard liquor; c, tail liquor; and d, cellar bottom water; 2, a sand feeding stage: uniformly mixing the a, b, c and d to obtain special fermented grains; 3, spreading a layer of special fermented grains at the bottom of a cellar, then, spreading steamed rice husks, and then, spreading common fermented grains for fermentation; 4, performing coarse sand and primary fermentation, taking out the special fermented grains at the bottom, adding the special fermented grains when the secondary common fermented grains are loaded to a retort opening by about 30cm, spreading the special fermented grains to be aligned with the retort opening, and distilling the flavored liquor at the bottom of the cellar to obtain a secondary Maotai-flavor flavored liquor; and 5, after the secondary liquor distillation is finished, independently taking out the special fermented grains on the upper layer of a retort to replace the a in the step 1, repeating the operation according to the step 2, and carrying out liquor distillation operation in the third, fourth and fifth rounds. According to the method disclosed by the invention, Maotai-flavor flavored liquors with various different flavors can be obtained.

Owner:劲牌茅台镇酒业有限公司

Strong flavour orange wine brewing method

InactiveCN106754013APure fruityAvoid it happening againAlcoholic beverage preparationYeastManufacturing technology

The invention discloses a strong flavour orange wine brewing method and belongs to the field of brewing wine. The strong flavour orange wine brewing method comprises the following steps: selecting wine brewing fruits, extracting a juice, carrying out fermentation, making distiller yeast, carrying out fermentation and distillation, and brut wine storage. In the juice extraction and fermentation step, fruits are squeezed to extract the juice after being peeled, sugar is added to regulate the sugar degree and then a pH value, then the juice subjected to regulation is poured in a fermentation vessel subjected to sterilization to carry out spontaneous fermentation, and spontaneous fermentation liquid is obtained. The strong flavour orange wine brewing method has the characteristics of eliminating a bitter and astringent taste caused by brewing the wine with oranges, brewing strong flavour wine with an orange taste, adding various taste selections for the wine, improving the own taste of the wine at the same time and adding feelings of sweet, moisturizing and soft taste and enjoyable aftertaste for the strong flavour wine so as to enable the strong flavour wine to be richer in taste and become popular among more consumers; and improving the manufacturing technology and lowering the total content of formaldehyde in the wine.

Owner:彭万洪

Solid-state fermentation type Huilou yam liquor and preparation process thereof

The invention relates to a solid-state fermentation type Huilou yam liquor and a preparation process thereof, belonging to the technical field of food processing. The yam liquor provided by the invention uses Huilou yams and Ganoderma lucidum yams as main raw materials and sorghum, glutinous rice and wheat as auxiliary materials and is prepared by filling a special pit with the main raw materialsand the auxiliary materials and carrying out solid-state fermentation. According to the invention, the method of infiltrating yam raw materials with after-run is adopted to overcome the problem that yams have too great viscosity and are prone to caking and difficult to ferment after cooking through steaming, and the method reduces material viscosity and maximally reserves nutrients in the yams. The prepared Huilou yam liquor has stable quality, presents the same gas quality and fragrance as traditional liquor, reserves nutrients in the Huilou yams and the Ganoderma lucidum yams, and is capableof invigorating the spleen, nourishing the stomach, relaxing bowels, maintaining beauty, nourishing yin and tonifying yang.

Owner:惠可荣

Production process of a high-quality Luzhou-flavored seasoning wine

The invention discloses a production process of high-quality strong-flavor type seasoning wine, which belongs to the field of wine production. Each production period of the process comprises two fermentation rounds, the first round comprises procedures of crushing raw materials, steaming to sterilize, feeding into a pond at low temperature, cooling down, adding yeast and feeding into a kiln for fermentation; the second round comprises procedures of discharging from the kiln, stirring tail wine, cooling down, adding yeast, feeding into a pond for fermentation and the like. According to the production process, through steps of distilling in gentle fire and taking the wine in different sections, the tail wine part is added into the second round of blending step, and the operation is circulated so as to obtain the strong-flavor seasoning wine of different grades. According to the production process, five grains, namely, sorghum, rice, sticky rice, wheat and corn, are taken as raw materials, high / medium yeast is used as a saccharifying fermentation agent, the raw materials are fed into the pond at low temperature, a unique sand-casting process is adopted for slowly fermenting in two rounds, the content of alcohol substances in the seasoning wine is increased, and strong pit flavor is achieved.

Owner:QINGDAO LANGYATAI GRP

Method for improving baijiu quality through biocatalysis of fat

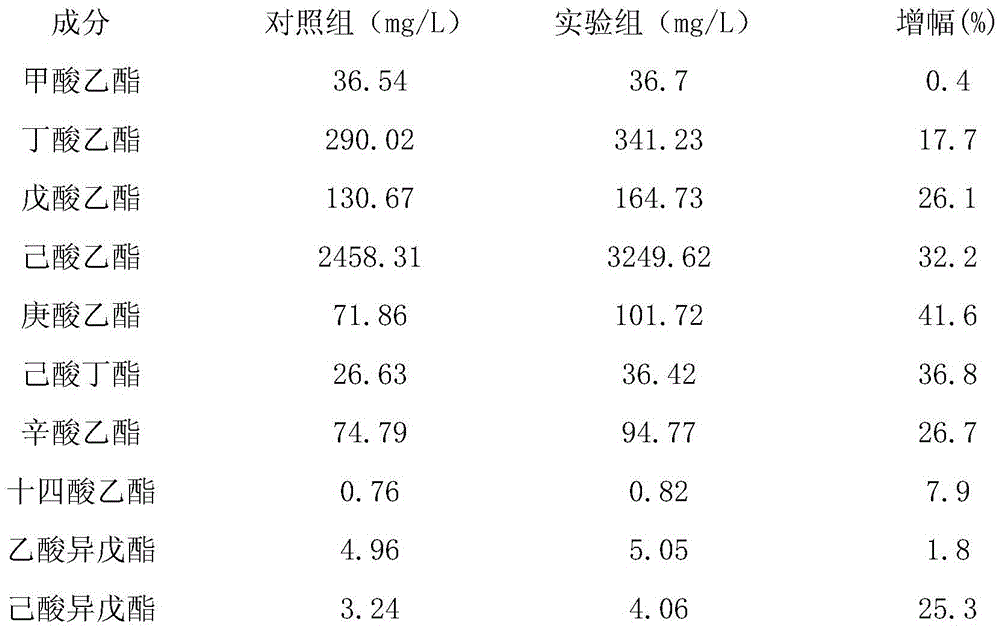

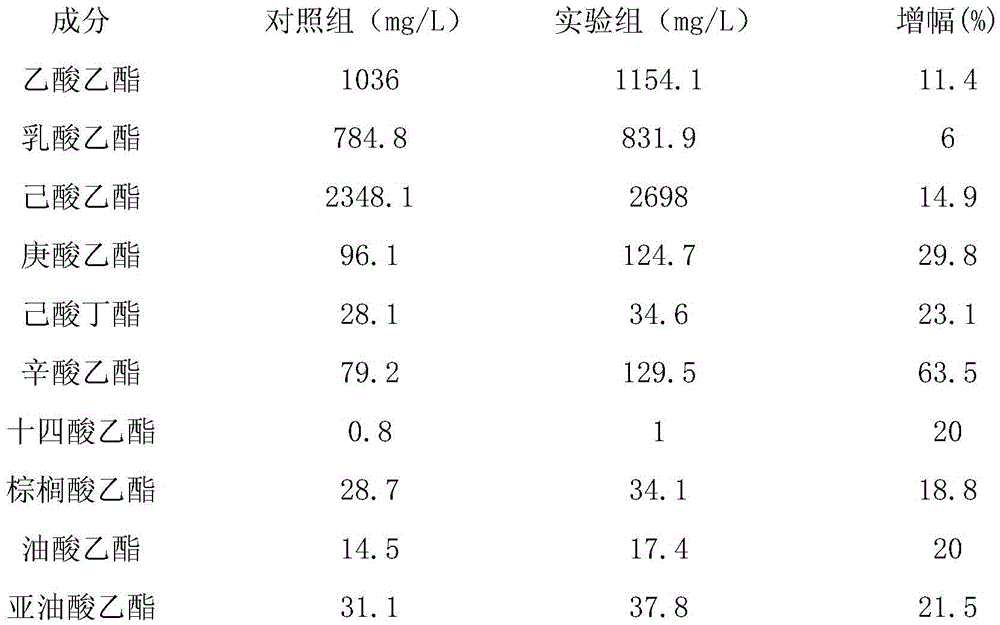

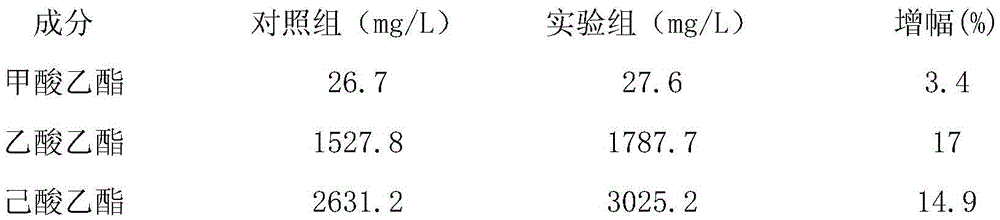

InactiveCN105420031AProminent ester aromaImprove quality stabilityAlcoholic beverage preparationFiberIncreased Lipolysis

The invention provides a method for improving the baijiu quality through biocatalysis of fat and belongs to the field of enzyme engineering and fermentation engineering. The method includes the following steps that a, 60-75 weight parts of starch, 8-12 weigh parts of protein, 1-5 weight parts of fibers and 3-7 weight parts of fat are taken as raw materials, water with the weight being 55-80% of the weight of the raw materials is added for wetting grains after coarse crushing, rice husks with the weight being 4-8% of the weight of the raw materials is taken and placed into a pot to be steamed while grain wetting is performed, and mixed cooling is performed according to the weight part ratio of the sum of the wet grains and the steamed rice husks to baijiu vinasse being 1:3 to 1:7; b, when the grain fermentation temperature in the step a is 30-40 DEG C, traditional yeast for making hard liquor with the weight being 20-40% of the weight of the raw grains, yeast mouldy bran with the weight being 2-8% of the weight of the raw grains, and lipase with the weight being 1-4%o of the weight of the raw grains are added and evenly mixed to be put into a pond to be fermented for 30-60 d at 20-40 DEG C, wherein the lipase is prepared from by lipolysis enzyme, easter synthesizing enzyme and transesterification enzyme according to the weight part ratio of 3: (0.98-1.03): (0.4-0.6); c, after fermentation in the b step ends, layered distillation is performed, and raw baijiu is obtained.

Owner:袁建国

Brewing method of Luzhou-flavor liquor

InactiveCN106520498AStrong cellar aromaLong aftertasteAlcoholic beverage preparationDistillationInorganic ions

The invention discloses a brewing method of Luzhou-flavor liquor, and belongs to the field of wine making. The brewing method of the Luzhou-flavor liquor comprises steps of preparing a distiller's yeast, conducting fermentation and distillation, and storing a liquor base. In the step of conducting fermentation and distillation, raw materials are fermented in a mode of being mixed with activated water, and the activated water undergoes ionization and is added with inorganic ions. The Luzhou-flavor liquor brewing method provided by the invention has the characteristics that the Luzhou-flavor liquor is improved; on the basis of reserving the properties of the Luzhou-flavor liquor which is intense in pit flavor and lasting in aftertaste, the feelings of being sweet and soft and being fresh and clean in aftertaste are added for the Luzhou-flavor liquor brewing method, so that the Luzhou-flavor liquor brewing method is more abundant in taste and is popular in more consumers; and meanwhile, a preparation process is improved and the total content of formaldehyde in the liquor is reduced.

Owner:彭万洪

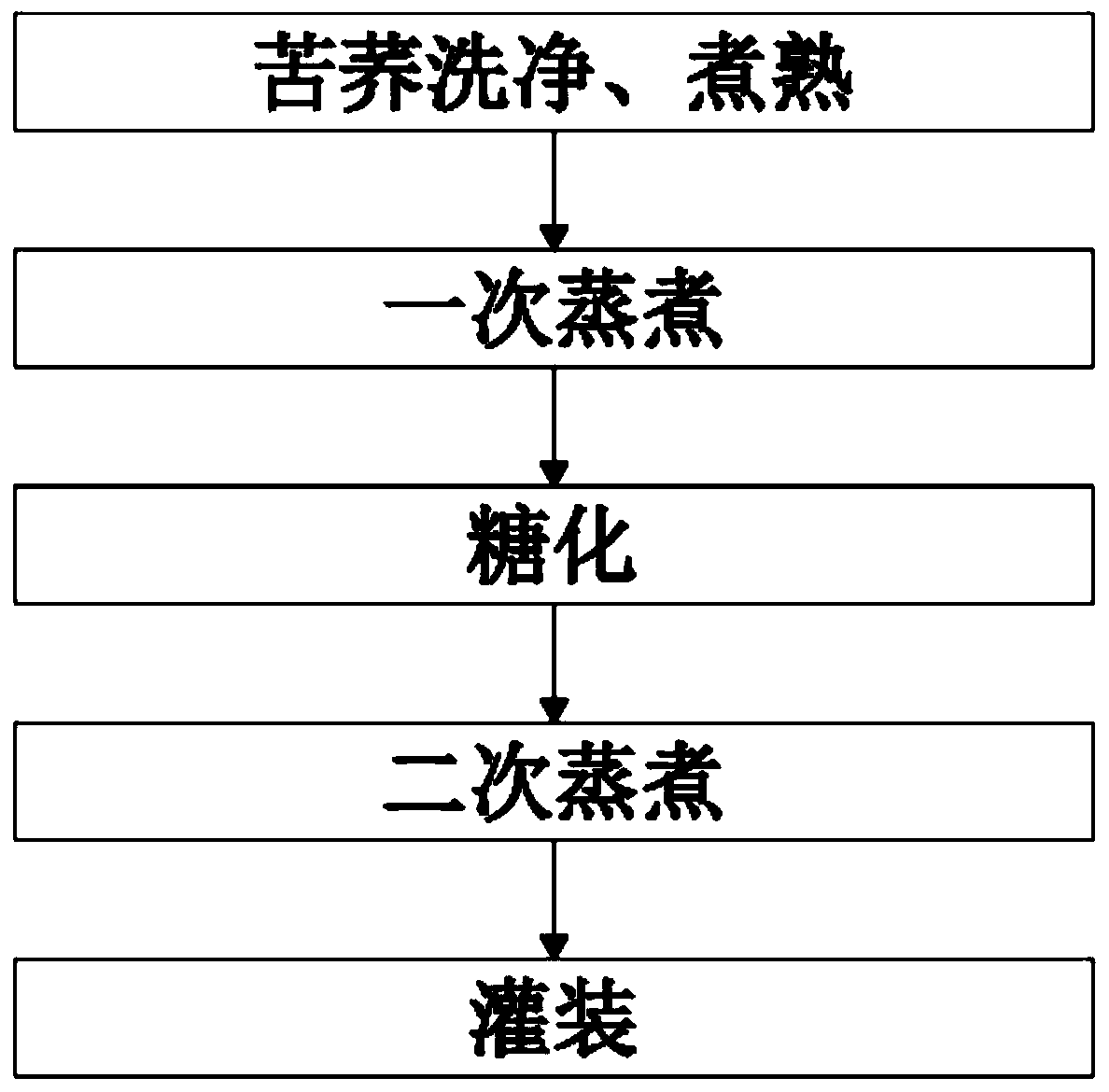

Tartary buckwheat health wine and preparation process thereof

PendingCN110484415AStrong cellar aromaColor golden transparentMetabolism disorderAntinoxious agentsPolygonum fagopyrumAcute hyperglycaemia

The invention belongs to the technical field of tartary buckwheat health wine, and relates to a tartary buckwheat health wine and a preparation process thereof. The tartary buckwheat health wine is prepared from pure tartary buckwheat wine, tartary buckwheat, root of kudzu vine, reed rhizome, rhizoma imperatae and bamboo leaves. The tartary buckwheat health wine is prepared from the following rawmaterials in parts by mass: 950-1050 parts of the pure tartary buckwheat wine, 4-6 parts of tartary buckwheat, 2-2.4 parts of root of kudzu vine, 2-2.4 parts of reed rhizome, 1.5-2.5 parts of rhizomaimperatae and 1.6-2 parts of bamboo leaves. The preparation process of the tartary buckwheat health wine comprises the following specific steps: S1, cleaning and cooking tartary buckwheat; S2, cookingfor the first time; S3, carrying out saccharification; S4, cooking for the second time; and S5, filling; the traditional white spirit style and the tartary buckwheat nutritional ingredients are reserved, the cellar fragrance and the tartary buckwheat fragrance are rich, the color is golden yellow and transparent, and the taste is soft and sweet; long-term drinking of the wine can enhance immunityand relieve hyperlipidemia, hypertension and hyperglycemia, and the wine has the functions of promoting the production of body fluid to quench thirst, clearing away heart-fire and eliminating vexation, inducing diuresis and excreting dampness, inhibiting bacteria, resisting aging, and beautifying face.

Owner:旺苍县鼓城纯粮酒厂

Fermentation method of fruity wine

InactiveCN107841415AStrong cellar aromaLong aftertasteAlcoholic beverage preparationOrganic acidBiotechnology

The invention discloses a fermentation method of fruity wine. The fermentation method mainly comprises the steps of finely selecting mandarin oranges, blueberries, apples, mangoes, kiwi fruits and pitayas; carrying out pulping and enzymolysis treatment; then mixing fruit pulp with cooked sticky rice and carrying out two times of fermentation in sequence to obtain the fruity wine. The fruity wine fermented by the fermentation method has rich cellar fragrance, long aftertaste, a sweet and soft mouthfeel and a clear aftertaste; the fruity wine is prepared by fermenting various fruits and high-quality sticky rice and is obtained through fermentation; the fruity wine contains abundant amino acids, organic acid and oligosaccharides; the prepared fruity wine has good nutrients and mouthfeel and is favored by more consumers.

Owner:方建兵

Method for improving total acid content and complex sense of strong-flavor base baijiu

ActiveCN110713877AReduce the proportionRaise the ratioAlcoholic beverage preparationBiotechnologyWine cellar

The invention discloses a method for improving the total acid content and complex sense of strong-flavor base baijiu and belongs to the technical field of baijiu brewing. According to the method, a concentration gradient of starch in a cellar is formed by optimizing the proportion of raw materials, the grinding degree and the material moistening mode and replacing a traditional dosing mode with anovel dosing technique of gradient dosing, and 'maintenance of fermented grains with a cellar, maintenance of the cellar with the fermented grains and mutual maintenance of the cellar and the fermented grains' can be promoted. By applying the technique, an excellent in-cellar fermentation condition is formed, the metabolic direction of microbes in a cellar is adjusted, and metabolism and production of acids and ester substances in fermented grains in the cellar can be favored, aroma and flavor producing substances in base baijiu can be increased, and the problems of low content of total acid and weak complex sense of base baijiu produced in a producing process can be effectively solved. When the technique is used in production of strong-flavor baijiu, the content of total acids of the basebaijiu is increased by 20-30 percent, and the base baijiu has rich cellar-aroma, mellow baijiu body and remarkably enhanced complex sense, is clear and fresh in aftertaste and has typical style of strong-flavor baijiu.

Owner:JIANGSU YANGHE BREWERY JOINT STOCK

Complex enzyme special for white spirit

InactiveCN101481682BHigh yieldDecompose fullyHydrolasesAlcoholic beverage preparationPectinaseFood flavor

The invention discloses a composite enzyme special for distilled spirit, which consists of cellulose, hemicellulose, beta-dextranase, diastatic enzyme, pectinase and protease. The composite enzyme special for distilled spirit has synergetic effect, and can effectively transform components such as starch, fat, protein and the like in raw materials and promote fermentation; while keeping fragrance of the distilled spirit in the fermentation process, greatly increase fragrant component content, speeds up reaction balance between alcohols, aldehydes, acids and esters, improves quality of distilled spirit, shortens fermentation period and shortens storage time. Production practices show that the composite enzyme special for distilled spirit which is used for fermenting distilled spirit improves yield and quality of distilled spirit without influencing flavor of primary wine. The composite enzyme special for distilled spirit can be applied to various distilled spirit production techniques with different conditions.

Owner:天津科建科技发展有限公司

Method for making wine by rice embryo buds

InactiveCN104745390AWine is nutritiousStrong cellar aromaAlcoholic beverage preparationWarm waterAdditive ingredient

The invention discloses a method for making a wine by rice embryo buds. The method comprises the following steps: taking 100 parts by weight of newly selected dry rice and pouring the newly selected dry rice in a cleaning pool, adding water with a distance of 10CM away from the level of the rice, soaking the rice for 72 hours with flowing water, and then draining water in the cleaning pool; then adding warm water at 30-36 DEG C and soaking until the rice cracks and exposes embryo buds; placing the rice which cracks and exposes the embryo buds in a wood retort and steaming for three hours with a strong fire, and splashing cold water and turning over the rice every half an hour during the period; removing the rice out when a malt aroma is sent from the wood retort; placing the rice on a cooling platform and flatly spreading, and adding 0.8-10 parts by weight of a yeast when the temperature is lowered to 30 DEG C; filling the rice mixed with the yeast in a mud urn, and saccharifying for 12-15 days at 27-30 DEG C; adding acid regurgitation water in a water weight ratio of 1: 1, adding 30-degree end white liquor in a ratio of 1: 8 after 5 days, and fermenting and cross-steaming for 15 days, and then distilling to obtain the wine. The wine made by the method disclosed by the invention contains many amino acids, volatile aroma ingredients, trace mineral elements and vitamins, and has popularization and use values.

Owner:谢传桂

Liquor and brewing process thereof

InactiveCN101302465BThe wine is clear and transparentStrong cellar aromaAlcoholic beverage preparationFlavorDistillation

The invention relates to white spirit - Manchu cave storage wine which inherits and summarizes the prior brewing technique and the modern science technology and a brewing technique for the Manchu cave storage wine. The Manchu cave storage wine is prepared by the following raw materials by weight ratio: the weight ratio of sorghum to fermented grains to rice hulls to Daqu powder is 1 to 4.5-5.0 to0.15-0.20 to 0.20 to 0.26. The brewing technique inherits and carries forward the unique white spirit brewing and storing techniques of Manchu, adopts luscious underground spring water, selects superior sorghum and minor cereals, takes intermediate and high temperature Daqu as saccharified ferment, and adopts the characteristics of the mixed multi-turn fermentation technique and the techniques such as fermentation in a mud fermentation pit, distillation in a stone pot, aged wine storage in a cave, elaborate blending and so on. The Manchu cave storage wine has limpid and transparent wine body,aromatic flavor of a fermentation pit, heavy wine body, coordinated flavors and clean taste, is pleasant after taste and has unique wind body style.

Owner:关健

Protection method for strong flavor spirit cellar pit mud

ActiveCN102703277BAvoid contactAvoid damageAlcoholic beverage preparationHigh probabilityMechanical equipment

The invention relates to a protection method for strong flavor spirit cellar pit mud, belongs to the technical field of brewing and solves the technical problems of high probability of causing stripping of the cellar pit mud during grain removal of mechanical equipment, grabbing of the bottom pit mud and distilled grains, and foreign flavor, discordance and uncleanness of the wine distilled from the distilled grains. The technical scheme for solving the technical problems is the protection method for the strong flavor spirit cellar pit mud. The protection method comprises the following steps of: a, cleaning cellar wall and cellar bottom after the fermentation is finished and the grains are removed; b, placing bamboo strips at the cellar bottom and the cellar wall; and c, charging in the cellar, sealing the cellar and performing a next cycle of fermentation. According to the preparation method, contact of the grain removal equipment and the cellar bottom or the cellar wall can be avoided, the damage caused to the cellar pit and the cellar mud during grain removal is effectively prevented, and the stability of the brewing performance of the cellar pit and the quality of base liquor are improved.

Owner:LUZHOU PINCHUANG TECH CO LTD

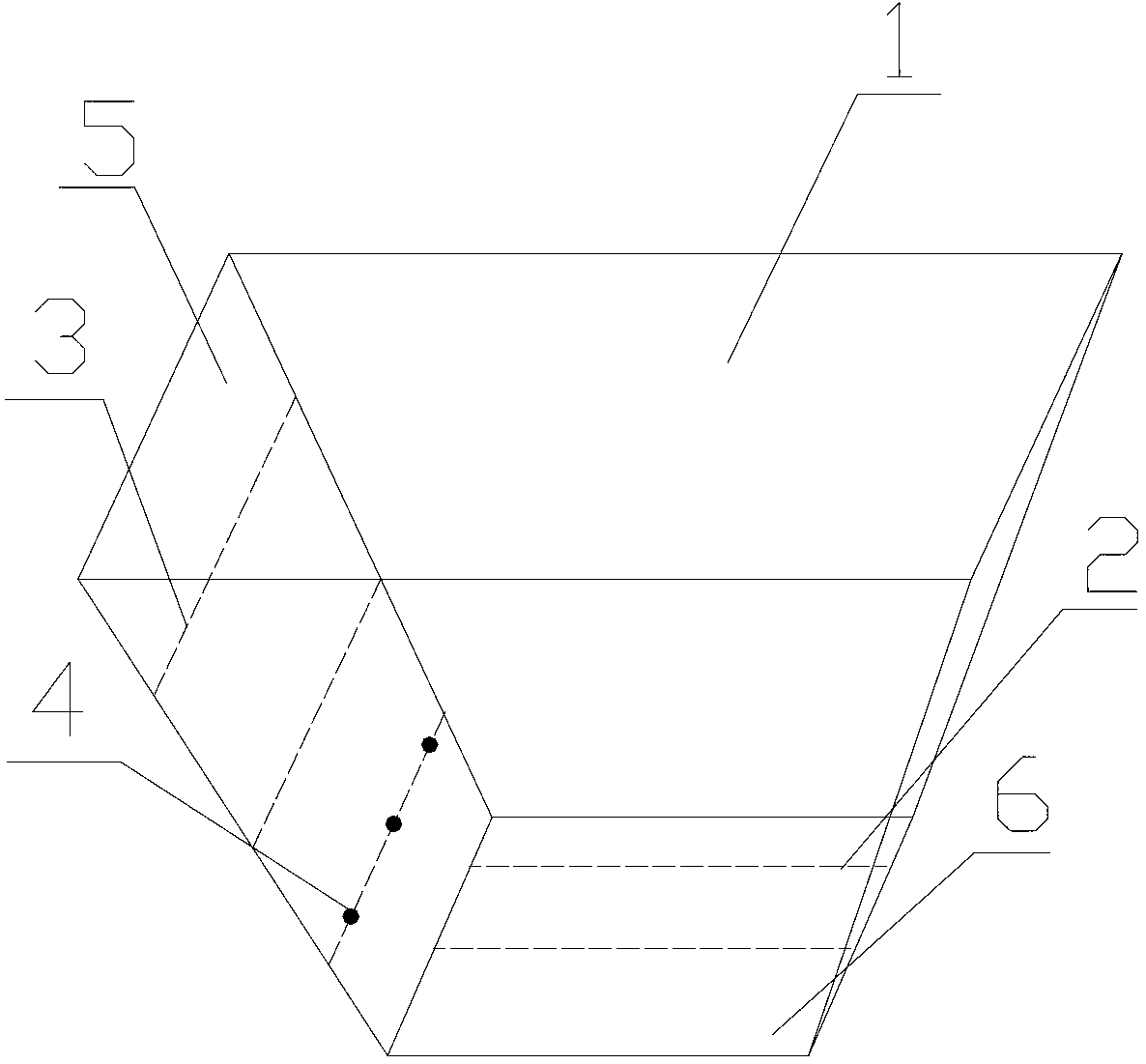

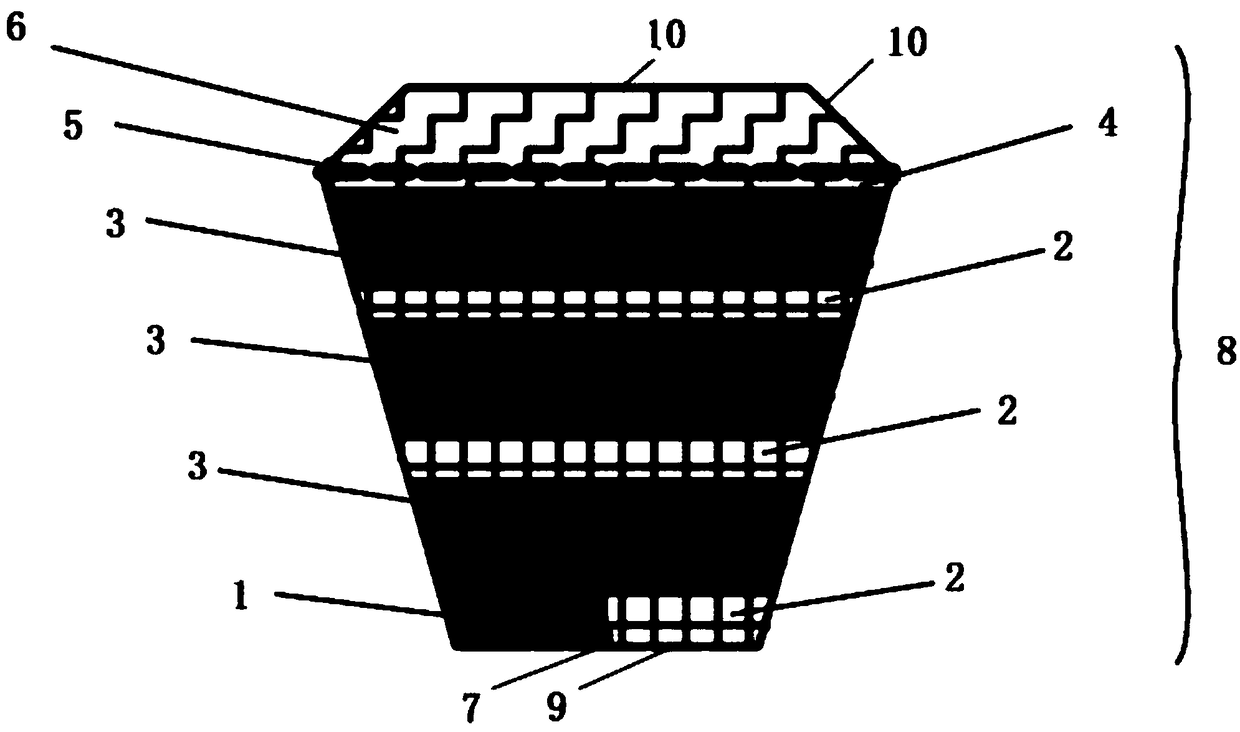

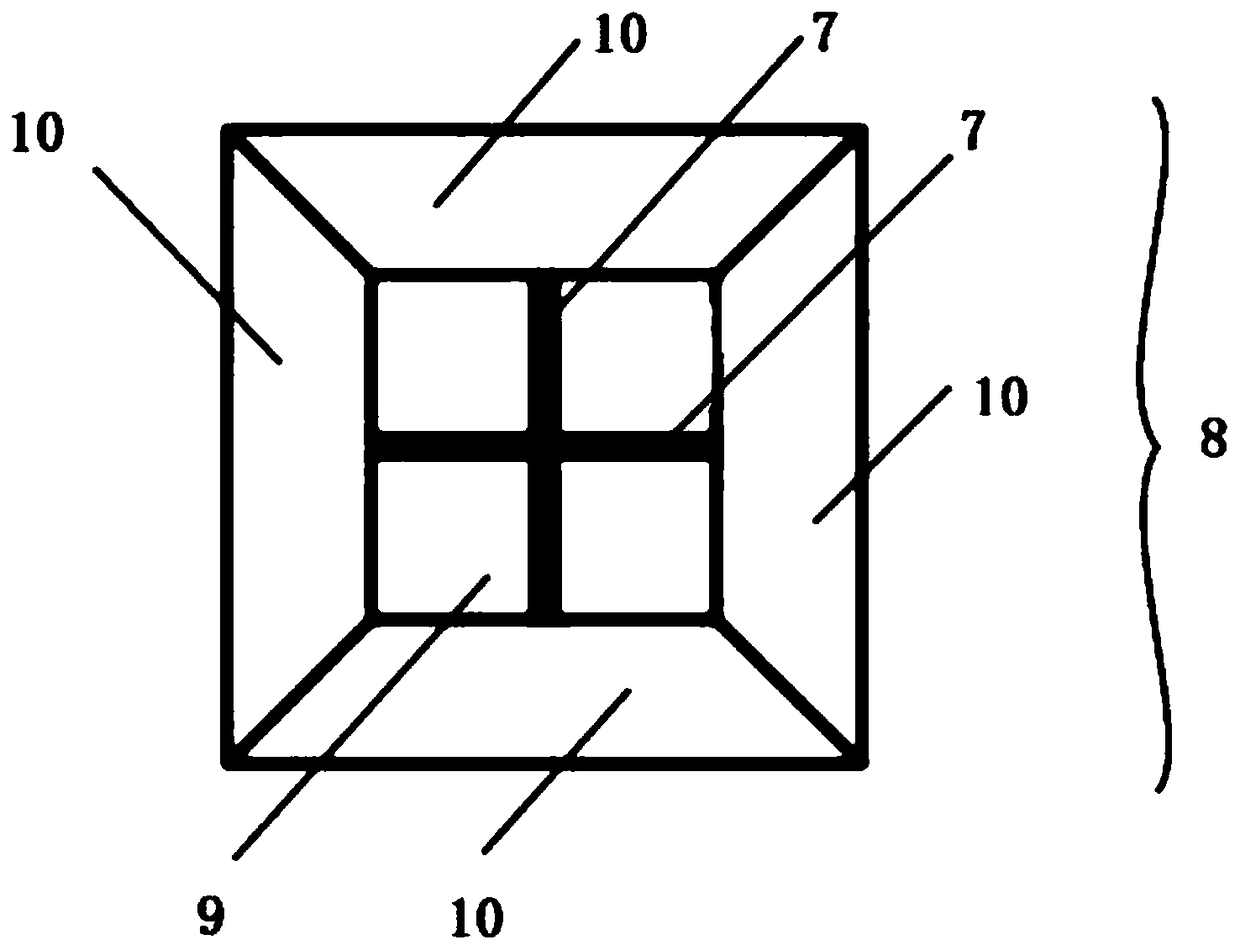

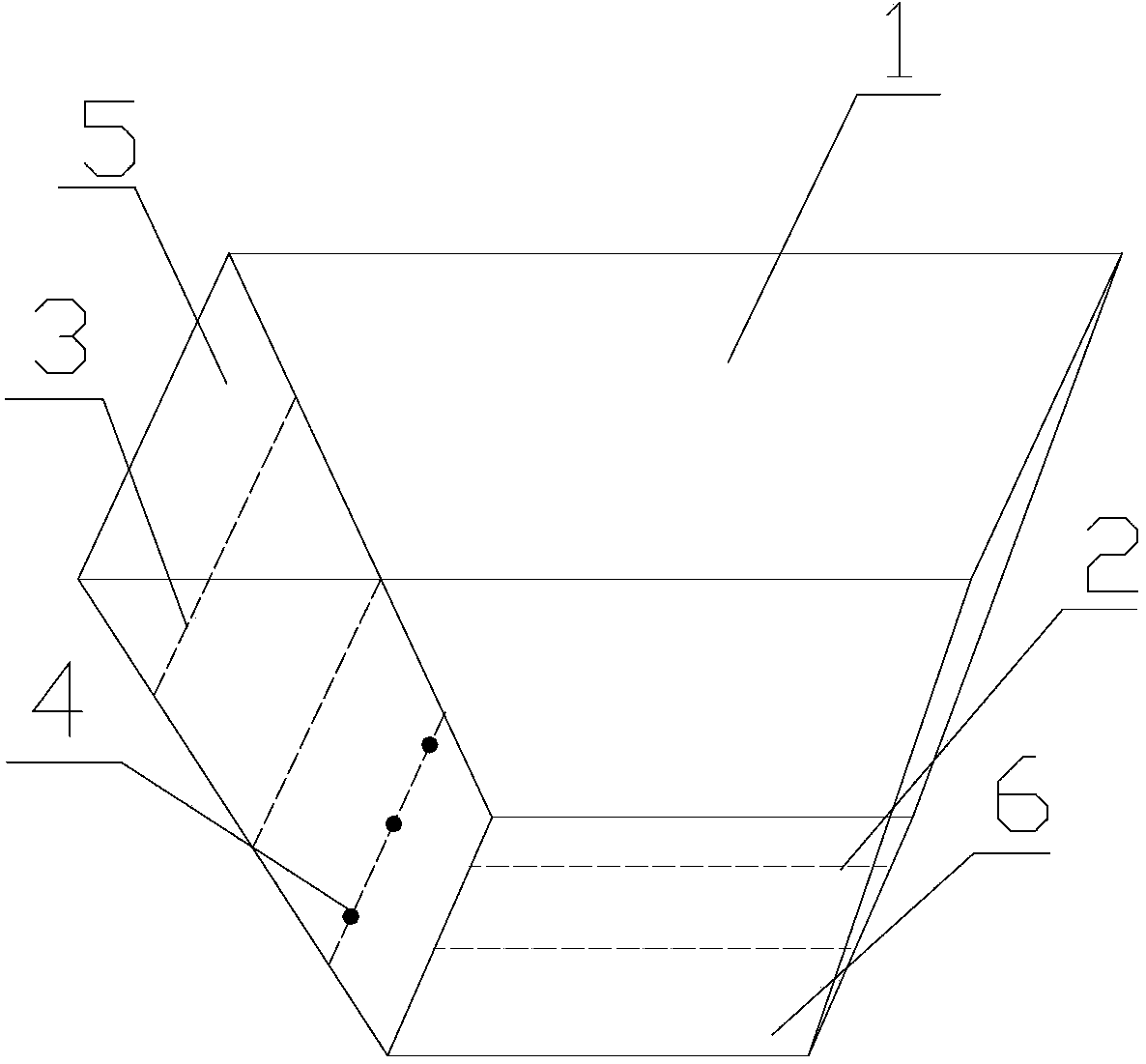

Ageing-flavor type ecological pit mud ageing fermenting pit and culture method of bionic thin layer of ageing-flavor type ecological pit mud ageing fermenting pit

ActiveCN107663500ARich varietyA large amountAlcoholic beverage preparationCellar toolsBrickEcological environment

The invention relates to the field of solid Baijiu brewing, in particular to an ageing-flavor type ecological pit mud ageing fermenting pit and a culture method of a bionic thin layer of the ageing-flavor type ecological pit mud ageing fermenting pit. The culture method comprises the following steps of manufacturing a fermentation pit by using stones or refractory bricks to build a wall and usinghigh-quality yellow mud to build a bottom, leaching the inner wall of the periphery of the standby fermentation pit with fresh high-quality yellow water, uniformly laying artificial pit mud on a compacted yellow mud layer at the pit bottom, inserting holes with unlimited shapes and diameters into the mud layer, then placing manufactured tray pit mud in the holes, and then sealing the pit with pitsealing mud for fermentation and culture for three cycles to obtain the ageing-flavor type ecological pit mud. The ecological pit mud solves the problem that the existing artificial pit mud can reachnaturally aged pit mud by still needing to be subjected to mutual maintenance of the pit and fermented grains of maintaining the pit with the fermented grains and maintaining the fermented grains withthe pit, a natural ageing period or an adaptation period and can enable a new pit to reach an aged pit level with continuous grain inputting fermentation and natural ageing for 20-35 years in the pitas being used for new pit hanging without being readapted to a difference change of a micro-ecological environment in the pit; brewed base liquor is mellow in taste, strong in pit flavor, elegant inageing flavor and long in aftertaste.

Owner:SICHUAN TUOPAI SHEDE WINE

Monascus aurantiacus

InactiveCN101993825BStrong specificitySynthetic strongFungiMicroorganism based processesLow activityYeast

The invention discloses an MN2 strain of Monascus aurantiacus. Esterifying enzyme produced by the strain has esterification activity of synthesizing longer straight-chain ester and can catalyze synthesis of four esters, in which ethyl caproate is taken as the main component, in strong aromatic yeast liquor, so that the aims of shortening fermentation period and improving liquor yield and high quality product rate are fulfilled, meanwhile, the problems of low activity of esterase produced by microorganism in a fermentation tank, lower concentration of reaction substrates such as alcohol, acid and the like and slow speed of etherification reaction are solved.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com