Ageing-flavor type ecological pit mud ageing fermenting pit and culture method of bionic thin layer of ageing-flavor type ecological pit mud ageing fermenting pit

A technology of fermentation cellar and cellar mud, which is applied in the cultivation field of old-flavor ecological cellar mud aging fermentation cellar and its bionic thin layer, which can solve the problems that the cultivation method cannot achieve natural aging, slowness, quality gap, etc. Quality improvement, strong environmental adaptability, and the effect of expanding production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

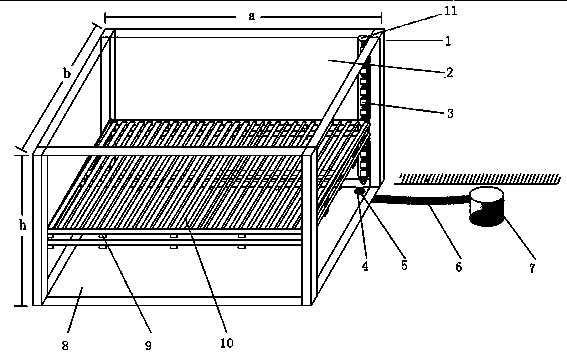

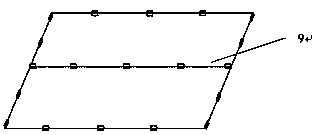

[0042] Such as figure 1 Shown is an old-flavor ecological cellar mud aging fermentation cellar. The cellar pool 1 is 3m long, 2.5m wide, and 4m high. Mud cellar bottom 8, feed inlet 11 reserved at the top, feed pipe 3 installed at the corner, drain hole 4 at the bottom corner of the cellar, and drain valve 5 installed on the hole; drain drain pipe is laid below the pit bottom plane 6. A liquid storage tank 7 is built at the other end of the dark passage; multi-layer stainless steel supports 9 are placed in the cellar, and the layer spacing of the upper and lower supports is 9 cm, and the column-shaped bamboo trays 10 are supported on the shelves, and the trays of the same layer are placed next to each other.

[0043] Using the above-mentioned cellar mud aging fermentation cellar to carry out the cultivation method of bionic thin layer, the main process is as follows:

[0044] 1. Cell wall cleaning. Take fresh high-quality yellow water to rinse the inner walls around the cell...

Embodiment 2

[0052] Such as figure 1 The old-flavored ecological cellar mud aging fermentation cellar is shown. The cellar pool 1 is 2m long, 3m wide, and 5m high. Cell bottom 8, feed inlet 11 is reserved at the top, feed cylinder 3 is installed at the corner, drain hole 4 is built at the bottom corner of the cellar, and drain valve is installed on the hole; 5, drain drain pipe is laid under the cell bottom plane 6 , build liquid reservoir 7 at the other end of dark passage; Place multi-layer stainless steel support 9 in the cellar, the interlayer spacing of upper and lower floor support is 6cm, supports column shape bamboo tray 10 on the frame, and the same layer tray is placed next to each other.

[0053] Using the above-mentioned cellar mud aging fermentation cellar to carry out the cultivation method of bionic thin layer, the main process is as follows:

[0054] 1. Cell wall cleaning. With embodiment 1.

[0055] 2. Make pit bottom mud. On the tamped yellow mud layer at the bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com