Method for improving baijiu quality through biocatalysis of fat

A biocatalysis and fat technology, applied in the field of enzyme engineering and bioengineering, can solve the problems of low compound lipase content, low fat utilization rate, affecting the content and richness of esters in liquor, etc., so as to improve the utilization rate of fat , quality stability improvement, and the effect of enriching the aroma components of liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Take 60 parts by weight of starch, 12 parts by weight of protein, 1 part by weight of fiber and 7 parts by weight of fat barley as raw materials, add 65 ° C raw material weight of 55% hydrated grains for 9 hours after coarse crushing, and water twice Add 60% first, then add the remaining water after two hours. While moistening the grain, take 8% of the raw material weight of rice husk and put it in the pot to steam the rice husk for 120 minutes, then stuff it for 10 minutes, and then follow (moisten grain + rice husk steaming) Material): Liquor distiller's grains = 1:3 weight ratio, mixing and dissipating heat to make grain unstrained spirits;

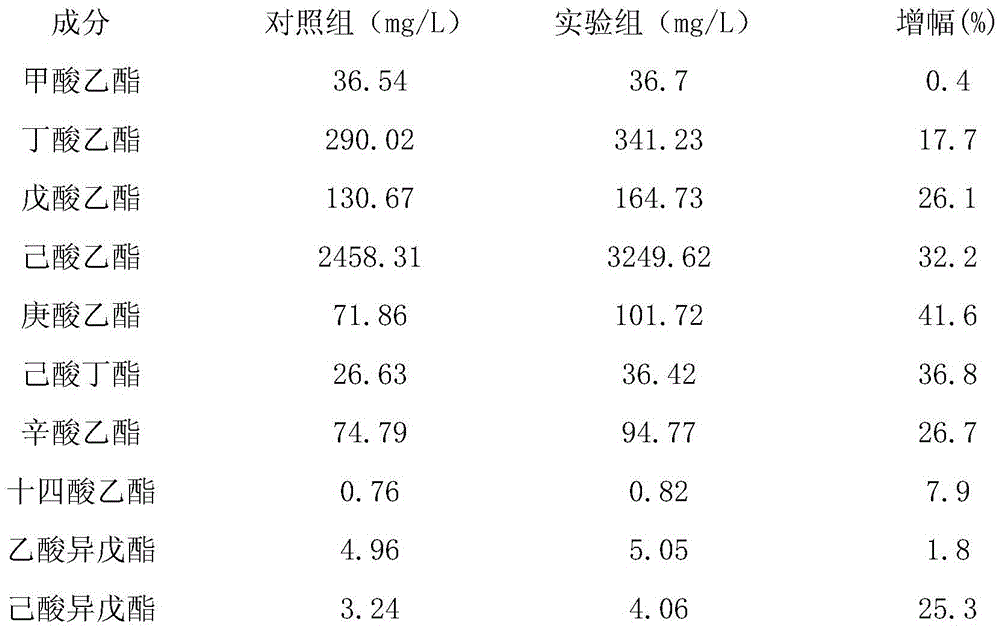

[0019] b. When the temperature of the grain unstrained spirits in step a is 30°C, add 40% traditional Daqu by weight of the original grain, 2% yeast bran koji, and 4‰ lipolytic enzyme: ester synthase: transesterase = 3:0.98: 0.6 parts by weight of lipase mixed in a proportioning ratio, after mixing, enter the tank for ferment...

Embodiment 2

[0024] a. Take 75 parts by weight of starch, 8 parts by weight of protein, 5 parts by weight of fiber and 3 parts by weight of fat as raw materials. After coarse crushing, add hydrated grain with 55% weight of raw materials at 80°C for 12 hours, and add water twice , add 40% first, and then add the remaining water after two hours. While moistening the grain, take 4% of the raw material weight of rice husk and put it in the pot to steam the rice husk for 70 minutes. : Liquor distiller's grains=1:7 by weight, mixing and dissipating heat to make grain unstrained spirits;

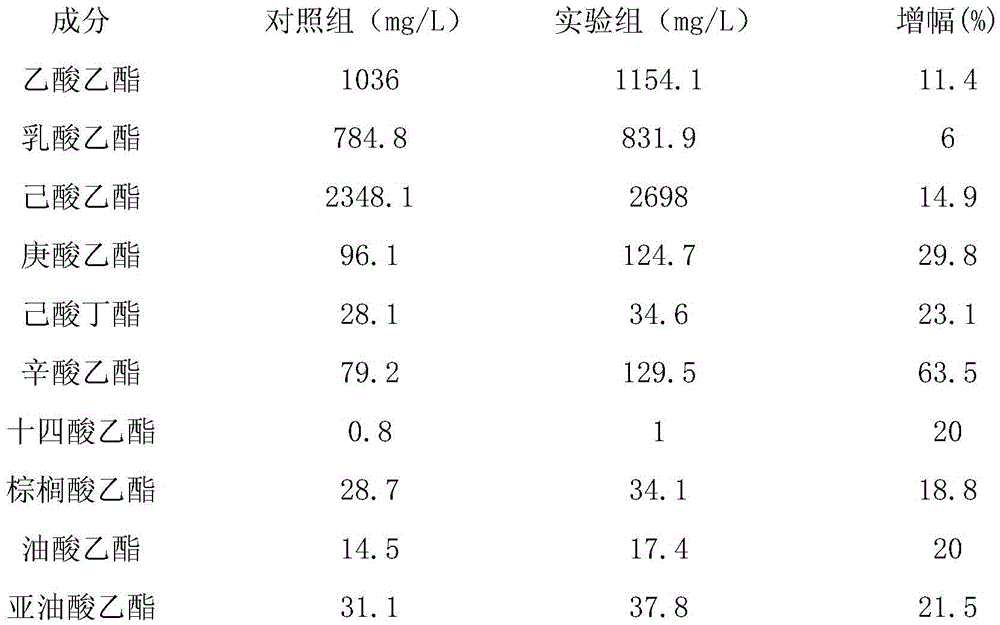

[0025] b. When the temperature of the grain unstrained spirits in step a is 40°C, add 20% traditional Daqu by weight of raw grain, 8% yeast bran koji, and 1‰ lipolytic enzyme: ester synthase: transesterase = 3:1.03: 0.4 parts by weight of lipase mixed in a proportioning ratio, after mixing, enter the tank for fermentation at 20°C for 60 days;

[0026] c. After the fermentation of step b is completed, the liquo...

Embodiment 3

[0030] a. Take 68 parts by weight of starch, 10 parts by weight of protein, 3 parts by weight of fiber and 5 parts by weight of fat as raw materials. After coarse crushing, add hydrated grains with 70% of the weight of raw materials at 72°C for 10 hours, and add water twice , add 50% first, then add the remaining water after two hours. While moistening the grain, take 6% of the raw material weight of rice husk and put it in the pot to steam the rice husk for 90 minutes, then stuff it for 25 minutes, and then follow (wet grain + rice husk steaming) : Liquor distiller's grains=1:5 proportioning by weight, mixing and dissipating heat to make grain unstrained spirits;

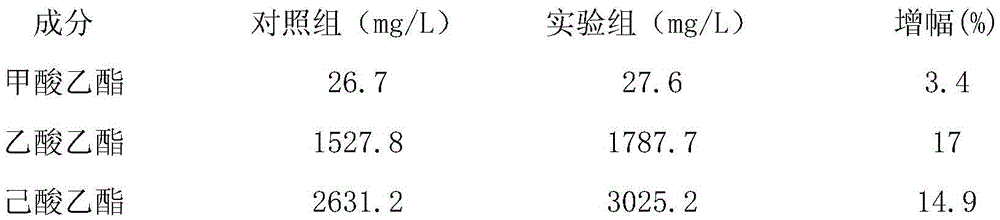

[0031] b. When the temperature of the grain unstrained spirits in step a is 35°C, add 30% of the weight of raw grain traditional Daqu, 6% of yeast bran koji, and 2.5‰ of lipolytic enzyme: ester synthase: transesterase = 3:1: 0.5 parts by weight of the lipase mixed in a proportion, after mixing, enter the tank for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com