Method for improving total acid content and complex sense of strong-flavor base baijiu

A technology with total acid content and strong aroma, which is applied in the field of wine making, can solve the problems of not being able to make full use of properties and location and environment characteristics, and achieve the effects of promoting the metabolism of anaerobic acid-producing microorganisms to produce acid, high protein content, and improving the cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

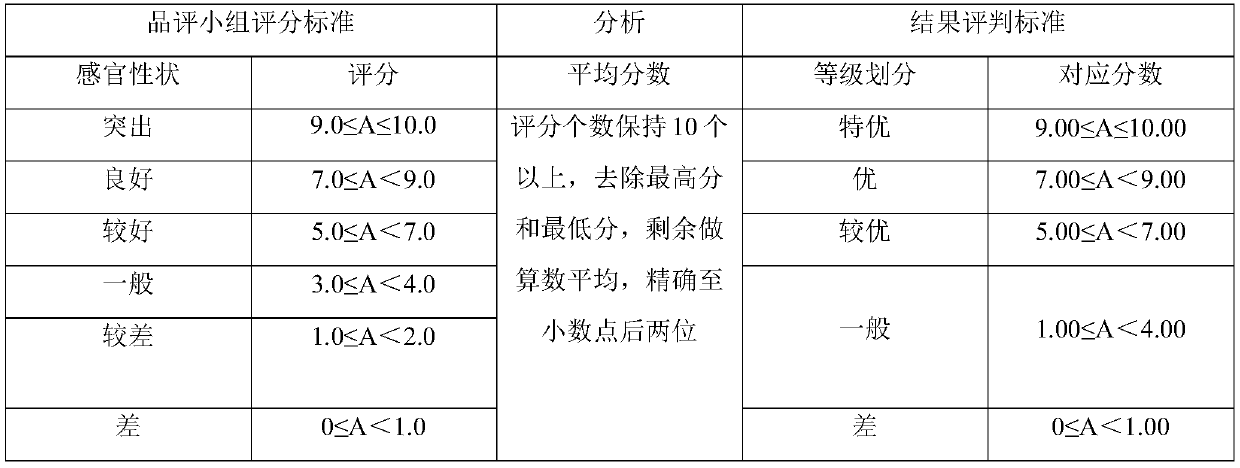

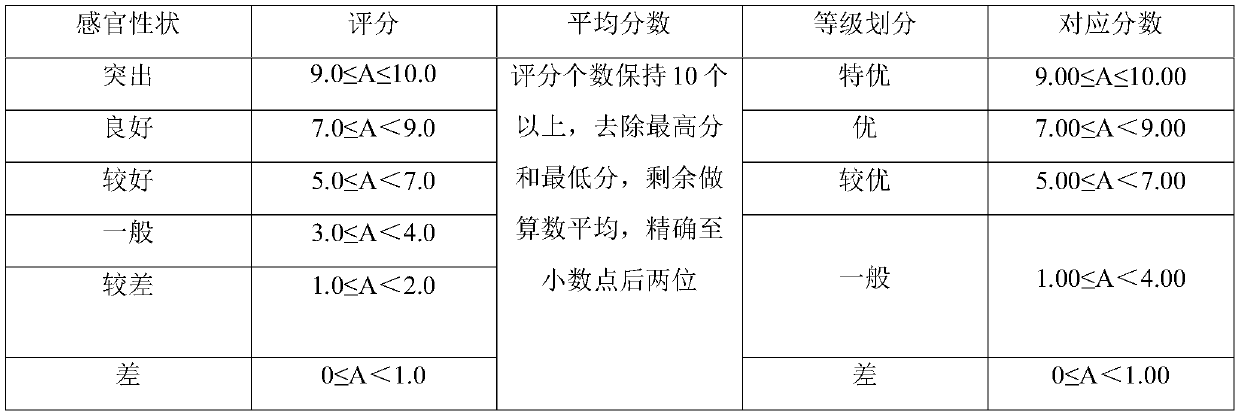

Image

Examples

Embodiment 1

[0070] a) Raw material and crushing degree: the total raw material consumption is 1100kg, and the proportioning composition is 300kg of sorghum, 310kg of rice, 150kg of glutinous rice, 150kg of wheat, and 100kg of corn. Rice and glutinous rice are whole grains, sorghum is crushed into 6-8 petals, wheat is crushed into 2-4 petals, and corn is crushed into 6-8 petals.

[0071] b) Moisturizing and splitting: fill the retort with water, adjust the water temperature to 30°C, pour all the rice and glutinous rice into the retort for soaking, the water surface is 10-20cm below the grain surface, and keep for 60 minutes; put all the sorghum , Wheat and corn are laid flat on the field, and 35% of the total weight of the raw materials is added to the normal temperature moistening water for 55 minutes; after the moistening is completed, all the raw materials are mixed evenly. Divide the above moistened raw materials into four parts A, B, C and D, wherein A is 100kg, B is 840kg, C is 50kg,...

Embodiment 2

[0080] a) Raw materials and crushing degree: the total raw material consumption is 1000kg, and the proportioning composition is 350kg of sorghum, 250kg of rice, 150kg of glutinous rice, 150kg of wheat, and 100kg of corn. Rice and glutinous rice are whole grains, sorghum is crushed into 6-8 petals, wheat is crushed into 2-4 petals, and corn is crushed into 6-8 petals.

[0081] b) Moisturizing and splitting: fill the retort with water, adjust the water temperature to 35°C, pour all the rice and glutinous rice into the retort for soaking, the water surface is 10-20cm below the grain surface, and keep for 50 minutes; put all the sorghum , Wheat and corn are laid flat on the field, and 40% of the total weight of the raw materials is added to the normal temperature moistening water for 50 minutes; after the moistening is completed, all the raw materials are mixed evenly. Divide the above moistened raw materials into four parts A, B, C and D, wherein A is 120kg, B is 790kg, C is 70kg...

Embodiment 3

[0090] a) Raw material and crushing degree: the total raw material consumption is 1000kg, and the ratio is composed of 440kg sorghum, 300kg rice, 100kg glutinous rice, 80kg wheat, and 80kg corn. Rice and glutinous rice are whole grains, sorghum is crushed into 6-8 petals, wheat is crushed into 2-4 petals, and corn is crushed into 6-8 petals.

[0091] b) Moisturizing and splitting: fill the retort with water, adjust the water temperature to 45°C, pour all the rice and glutinous rice into the retort for soaking, and keep the water surface for 10-20cm below the grain surface for 45 minutes; put all the sorghum , Wheat and corn are laid flat on the field, and 40% of the total weight of the raw materials is added to the normal temperature moistening water for 70 minutes; after the moistening is completed, all the raw materials are mixed evenly. Divide the above moistened raw materials into four parts: A, B, C and D, wherein A is 100kg; B is 800kg; C is 80kg; D is 20kg.

[0092] c)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com