Ironing device with textile fabric tension adjusting function

A tension adjustment and ironing device technology, applied in the field of textile fabrics, can solve the problems of inability to perform tension adjustment, continuous ironing effect, single work energy, etc., and achieves improved ironing efficiency, ironing automation, and obvious ironing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

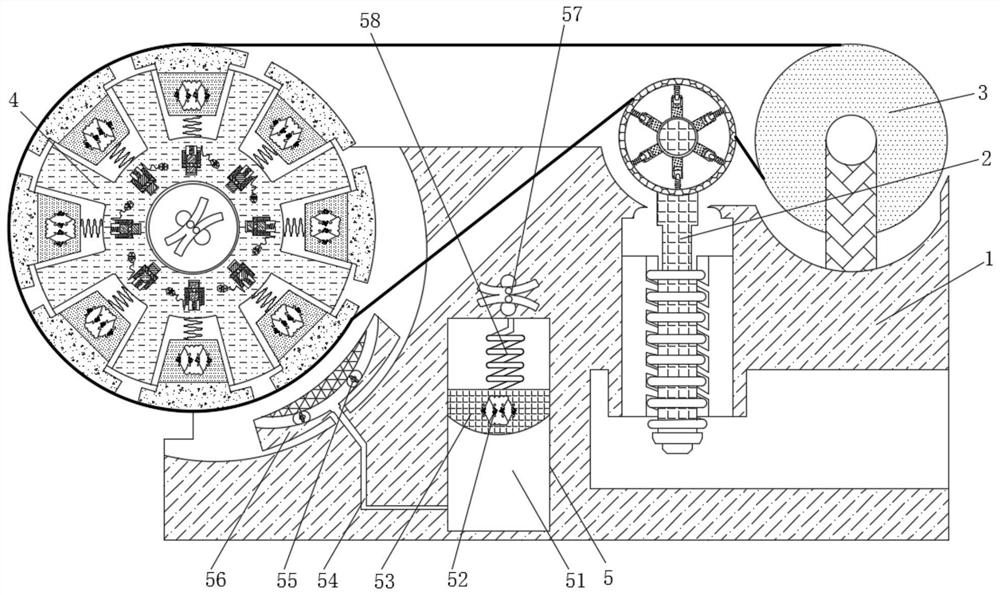

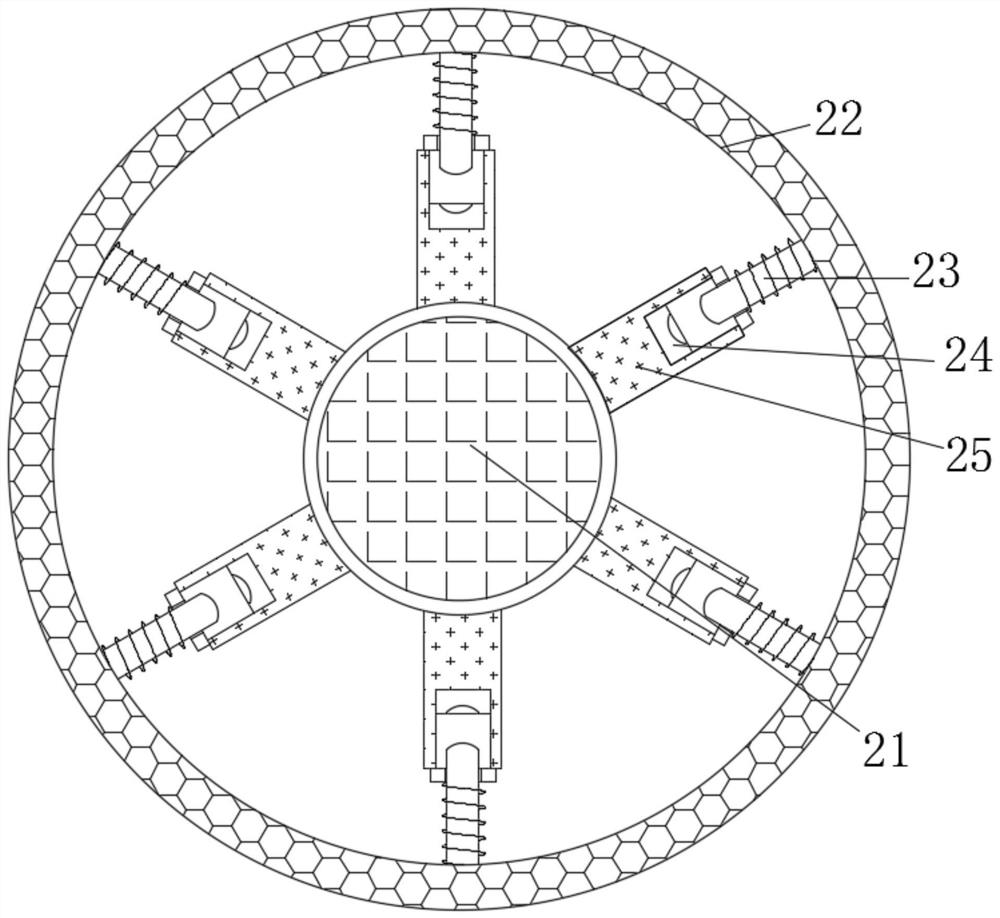

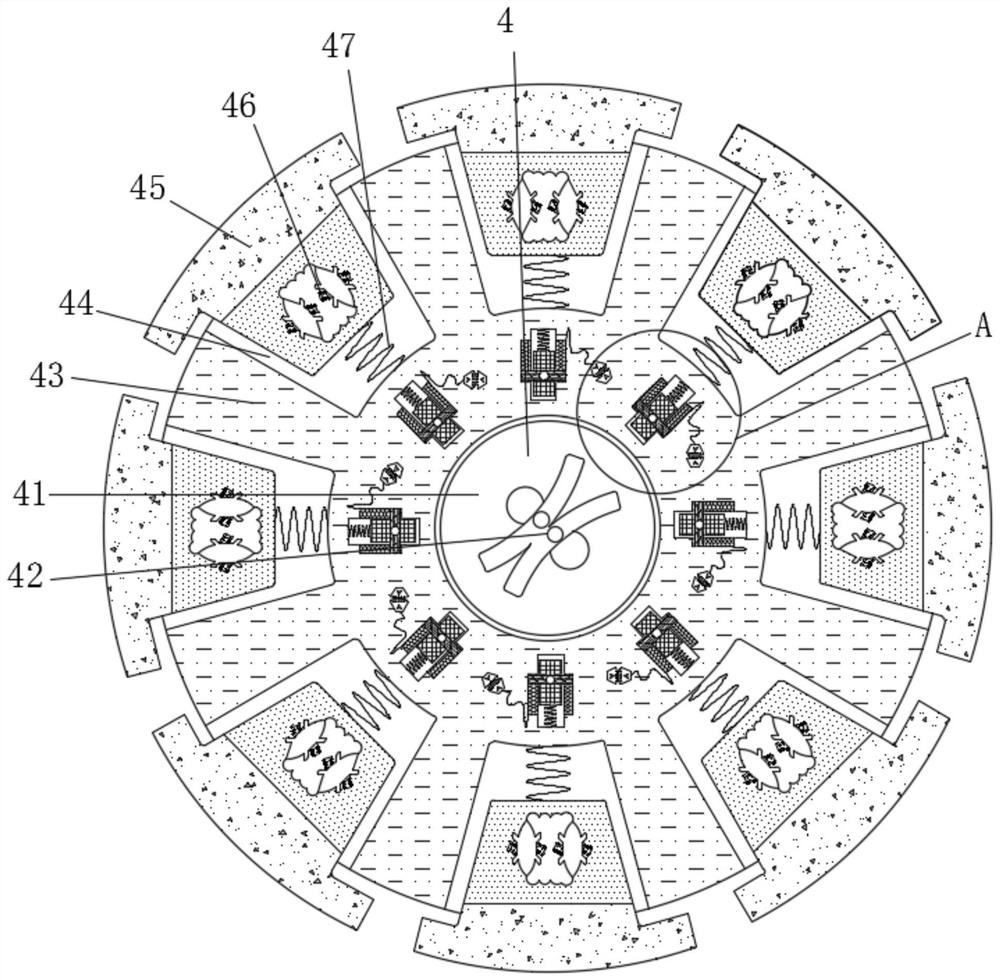

[0027] see Figure 1-4 , an ironing device for adjusting the tension of textile fabrics, including a housing 1, an adjustment mechanism 2, the adjustment mechanism 2 includes a screw 21, a rubber ring 22, a conductive spring column 23, a static contact 24, a connecting column 25, and the inner wall of the middle part of the housing 1 The screw rod 21 is movably connected, and the outside of the screw rod 21 is movably connected with a connecting column 25, and the inner wall of the middle part of the connecting column 25 is movably connected with a conductive spring column 23, and the outer side of the conductive spring column 23 is fixedly connected with a rubber ring 22, and the inner wall of the connecting column 25 is fixedly connected with a static The contact 24, the initial state of the conductive spring column 23 and the static contact 24 are in a separated state, the static contact 24 is electrically connected with the strong magnet 2 57, and the rubber ring 22 will pr...

Embodiment 2

[0030] see Figure 1-4, an ironing device for adjusting the tension of textile fabrics, including a housing 1, an adjustment mechanism 2, the adjustment mechanism 2 includes a screw 21, a rubber ring 22, a conductive spring column 23, a static contact 24, a connecting column 25, and the inner wall of the middle part of the housing 1 The screw rod 21 is movably connected, and the outside of the screw rod 21 is movably connected with a connecting column 25, and the inner wall of the middle part of the connecting column 25 is movably connected with a conductive spring column 23, and the outer side of the conductive spring column 23 is fixedly connected with a rubber ring 22, and the inner wall of the connecting column 25 is fixedly connected with a static The contact 24, the initial state of the conductive spring column 23 and the static contact 24 are in a separated state, the static contact 24 is electrically connected with the strong magnet 2 57, and the rubber ring 22 will pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com