Photo-curing ink-jet resist for printing circuit board and preparation method thereof

A printed circuit board and resist technology, which is applied in the field of light-curing inkjet resist and its preparation, can solve the problems of unfavorable PCB board resolution, slow photo-curing speed of etching-resistant ink, etc., and achieves good etching resistance, The effect of good alkali solubility and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

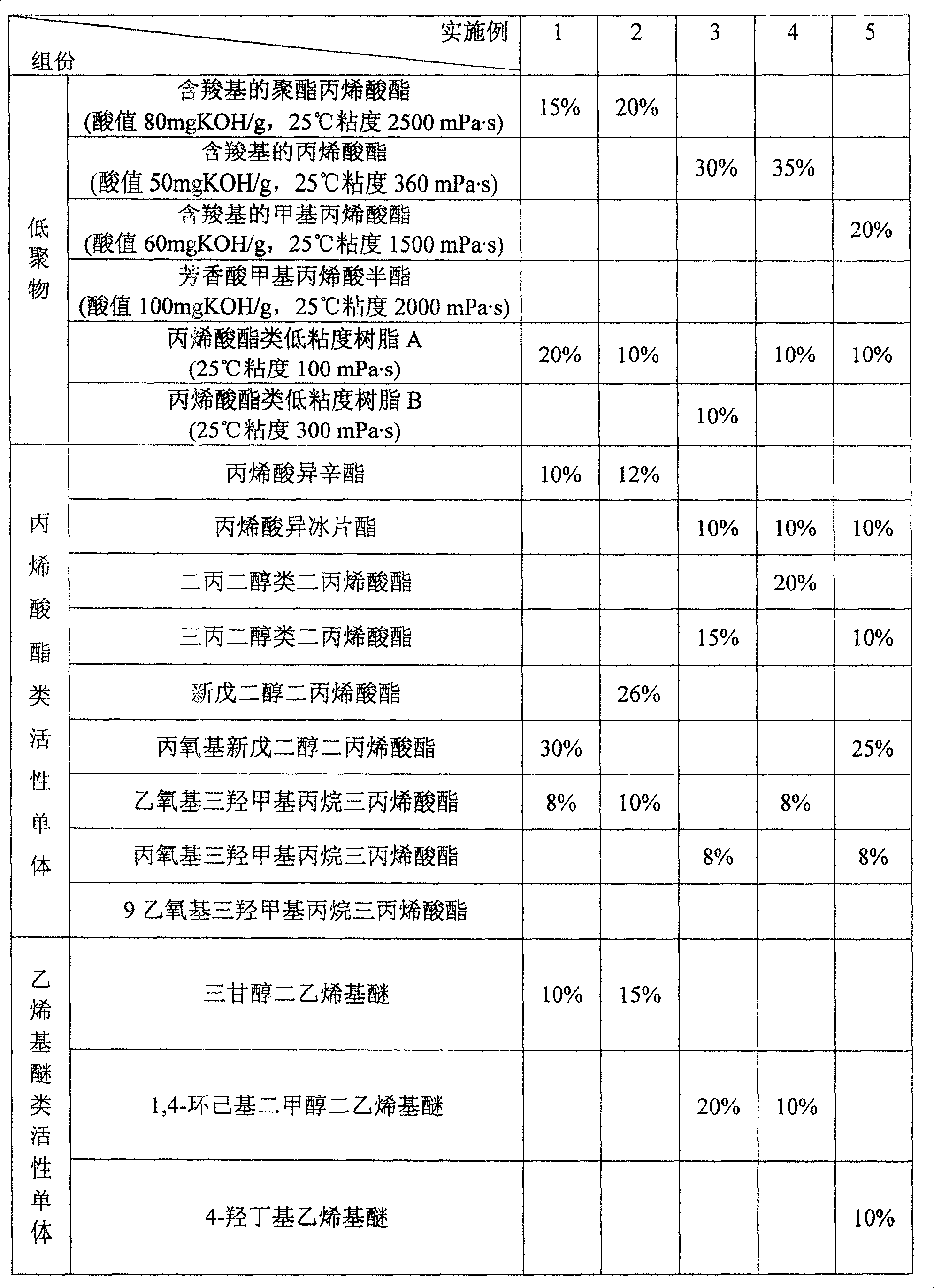

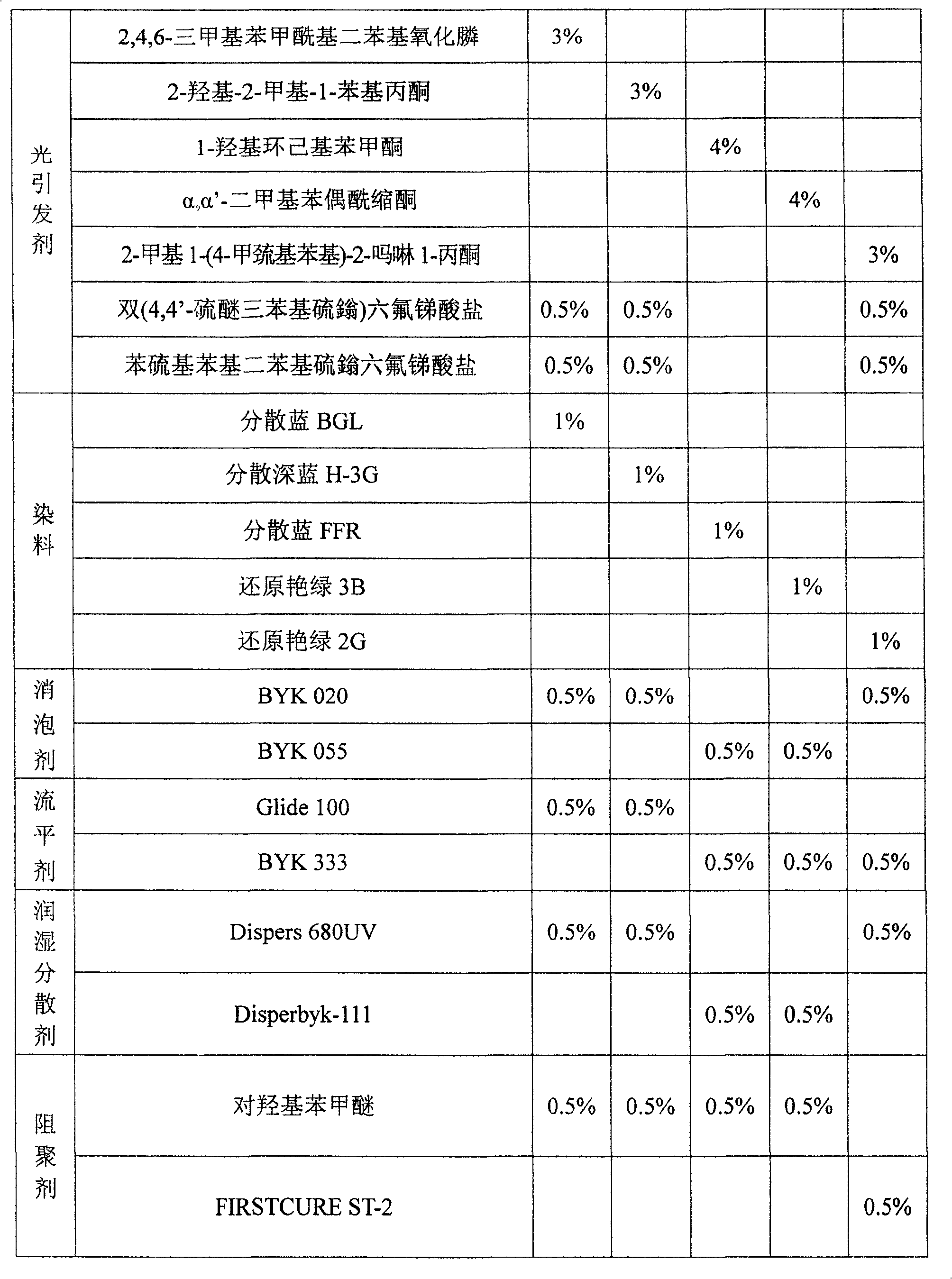

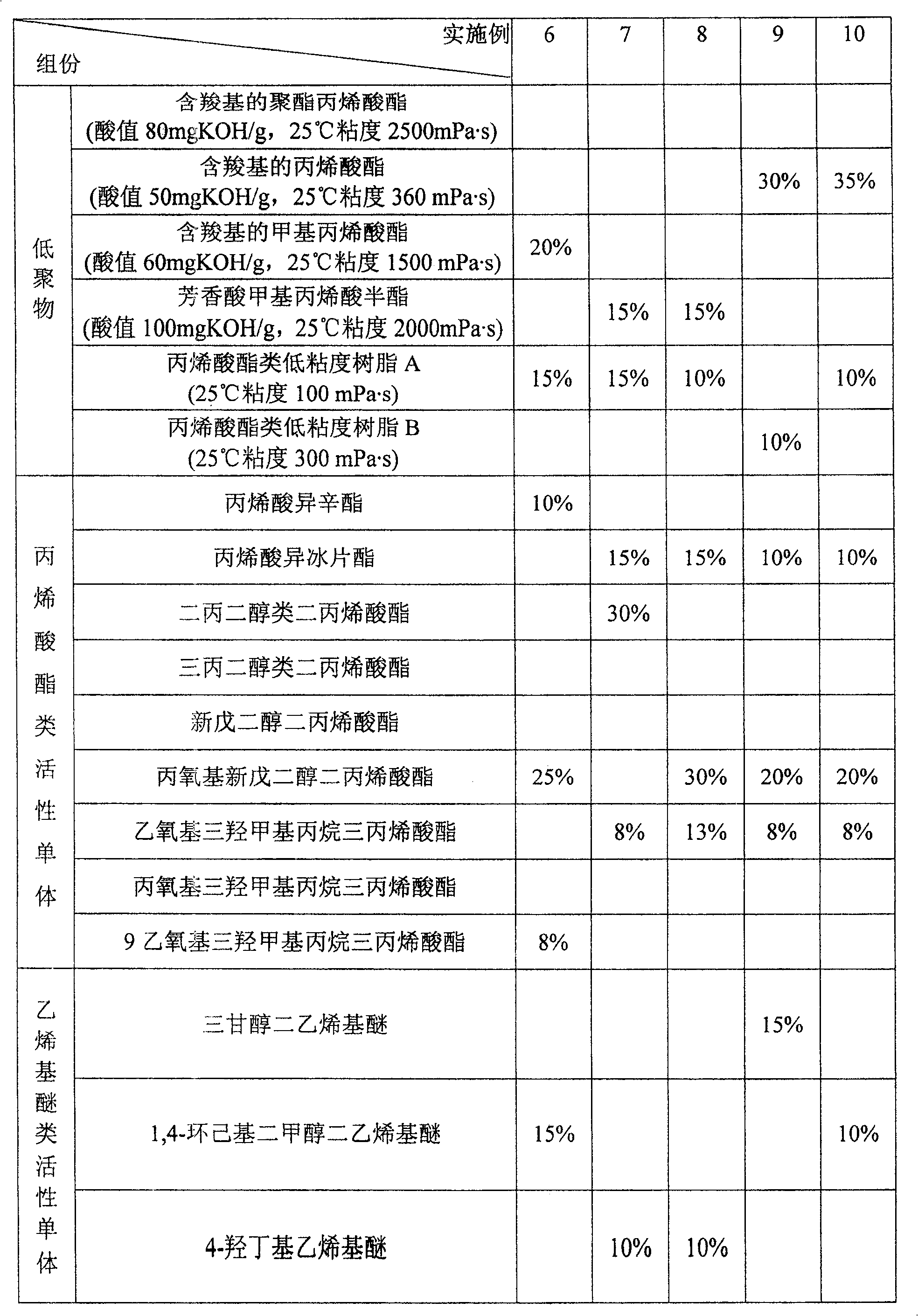

[0038] See Table 1 for the mass percentage of each component of the new photocurable inkjet resist prepared for printed circuit board (PCB). First, mix carboxyl-containing acrylate oligomers, acrylate low-viscosity resins, acrylate active monomers, and vinyl ether active monomers evenly, then add a photoinitiator under yellow light conditions, and heat up to 50 ℃ to fully dissolve the photoinitiator, then lower it to room temperature and add the dye in proportion, use a stirring, sand milling, and dispersing multipurpose machine to stir for 2 hours until the mixture is uniform, add leveling agent, wetting and dispersing agent, polymerization inhibitor, defoaming agent The agent is mixed evenly and obtained by filtration.

[0039] Use an inkjet printer to spray on the surface of the substrate, and then perform photocuring to obtain an experimental sample.

[0040] Table 1 The components and dosage (mass percentage concentration) of the new photocurable inkjet resist for PCB bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com