Method for uniformly dyeing fabric

A uniform dyeing and fabric technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of uneven dyeing of cloth, waste of dye liquor, excessive energy consumption, etc., and achieve the effect of improving dyeing uniformity, reducing waste, and promoting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

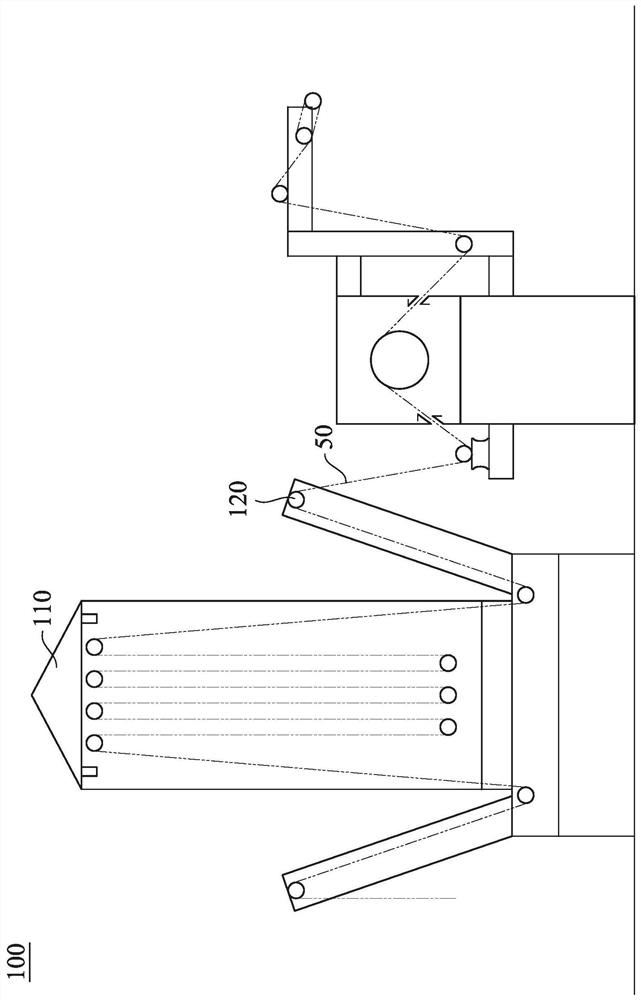

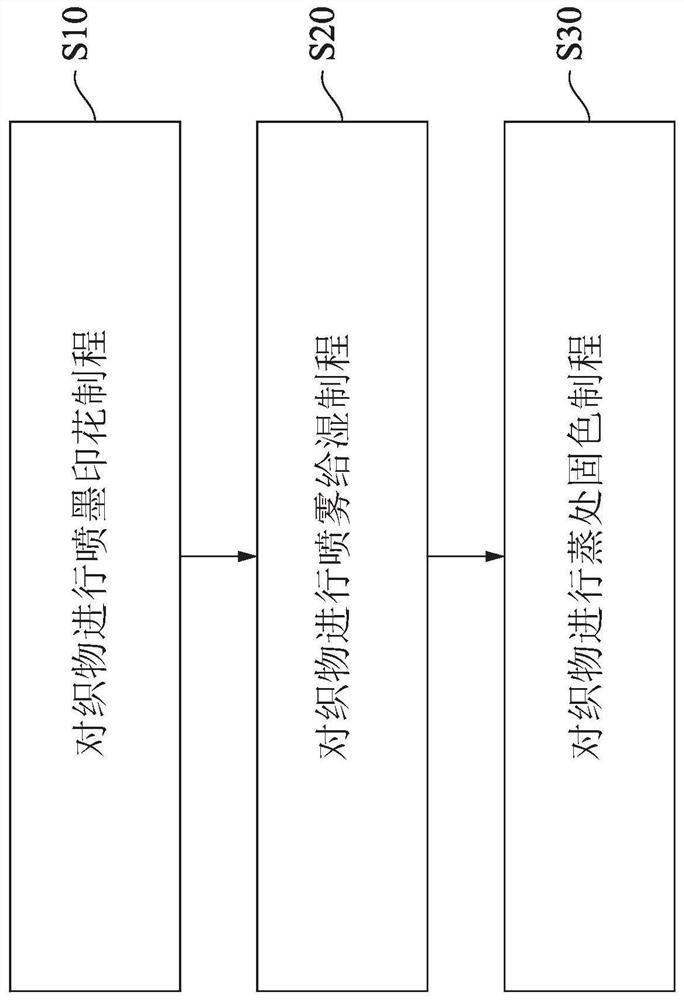

Method used

Image

Examples

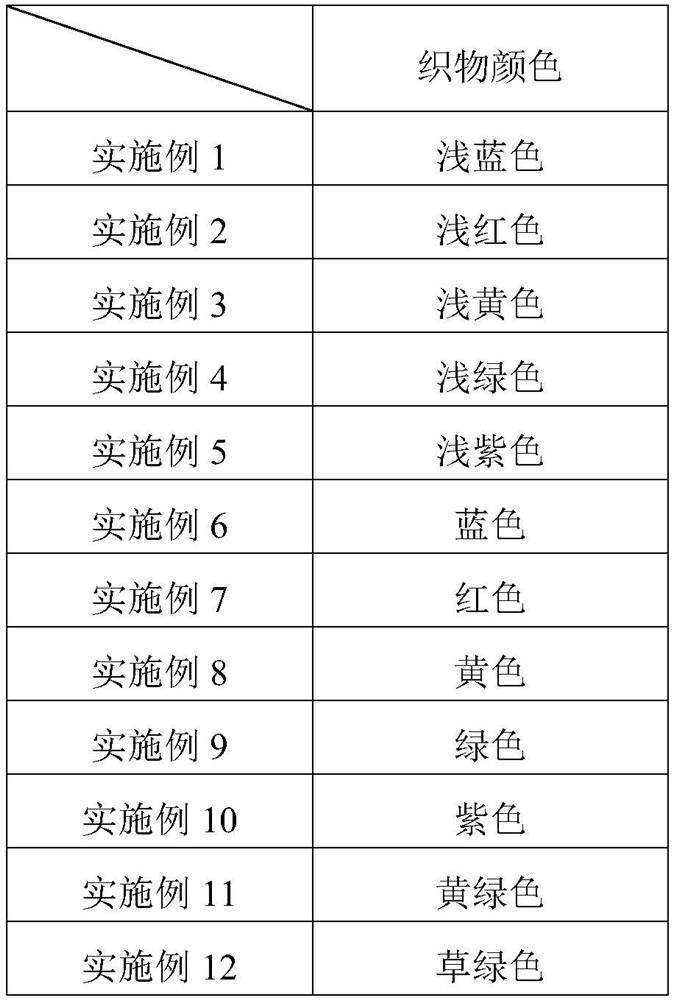

experiment example 1

[0041] Experimental Example 1: Evaluation of fabric color strength (K / S) and color difference (CMCΔE)

[0042] In this experimental example, a spectrophotometer (Datacolor) is used to measure the color strength value related to the color depth of the fabric and the color difference value related to the color difference of the fabric on the fabrics of Examples 1 to 10, wherein The color strength value of the fabric is obtained by measuring the absorbance of the fabric under the irradiation of visible light with a wavelength of 400nm to 700nm, and the color difference value of the fabric is obtained by collecting 4 sampling points on the surface of the fabric for Lab value measurement and averaging The value is calculated, and the circumference diameter of each sampling point is between 9mm and 30mm. The measurement results of the fabrics of each embodiment are shown in Table 2.

[0043] Table II

[0044]

[0045] As shown in Table 2, whether it is a dark-colored or light-c...

experiment example 2

[0046] Experimental example 2: Evaluation of the reproducibility of the color difference value (CMCΔE) of the fabric

[0047] In this experimental example, a spectrophotometer (Datacolor) was used to measure the color difference values of the fabrics of Examples 1 to 10 twice to evaluate the reproducibility of the color difference values of the fabrics, wherein the color difference of the fabrics The method for measuring the color difference value is the same as the method for measuring the color difference value used in Experimental Example 1, and will not be repeated here. The measurement results of the fabrics of each embodiment are shown in Table 3.

[0048] Table three

[0049]

[0050]

[0051] As shown in Table 3, regardless of whether it is dark-colored or light-colored fabrics, the difference in color difference between the two measurements is less than 0.26, which has good reproducibility. In addition, the color difference values of the fabrics in each ...

experiment example 3

[0052] Experimental example 3: Evaluation of color difference value (CMCΔE) of large-scale fabrics

[0053] In this experimental example, a spectrophotometer (Datacolor) is used to measure the color difference values of the fabrics of Example 5, Examples 7 to 9 and Examples 11 to 12, wherein Example 5, Example 7 to 9 and the fabric size of embodiment 11 are 10 yards, and the fabric size of embodiment 12 is 20 yards, wherein the measurement method of the color difference value of fabric is the same as the measurement method of the color difference value used in Experimental Example 1, here I won't go into details. The measurement results of the fabrics of each embodiment are shown in Table 4.

[0054] Table four

[0055]

[0056]

[0057] As shown in Table 4, the color difference values of the fabrics of Example 5, Examples 7 to 9, and Examples 11 to 12 are all less than or equal to 0.70, which meets the standard in the industry. It can be seen that the method for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap