Press-in type construction ventilation system for extra-long high-gas tunnel

A ventilation system and push-in technology, which is applied in mine/tunnel ventilation, tunnel, gas discharge, etc., can solve the problems of increasing the distance of fresh air on the right line, insufficient air supply, and difficulty in supplying air to the excavation surface, and improve safety. performance and efficiency, ensure the supply of fresh air, and facilitate the effect of normal free breathing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

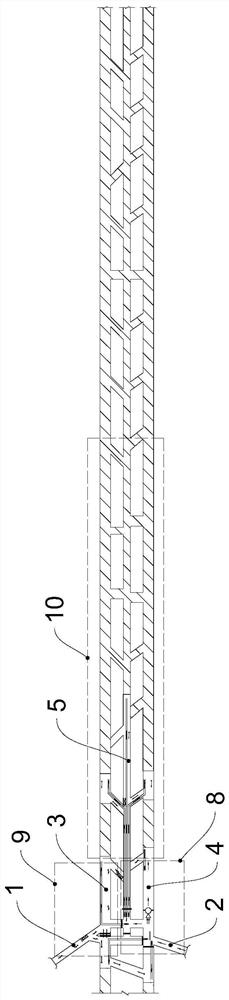

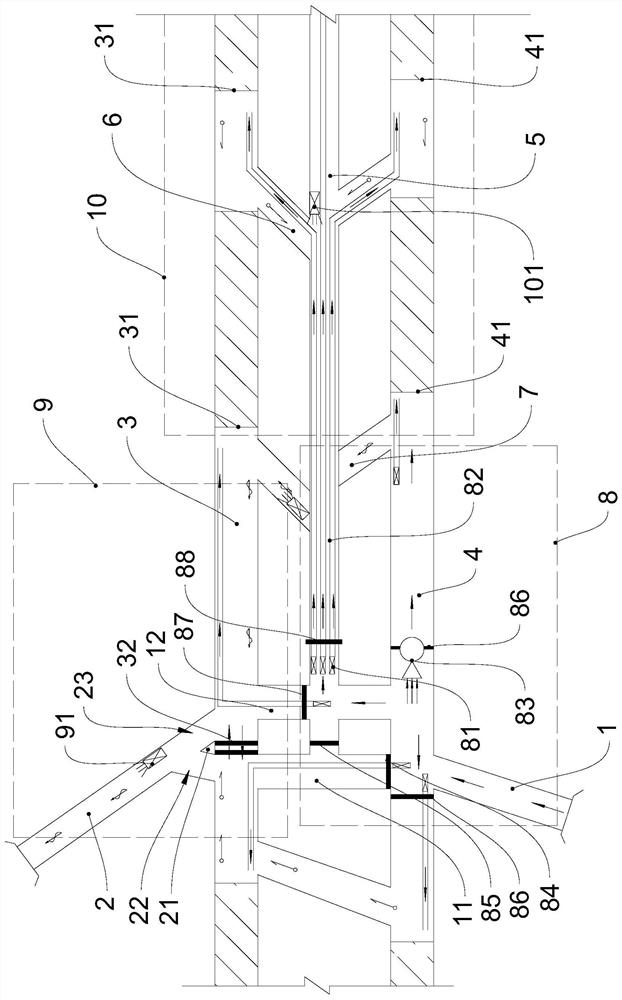

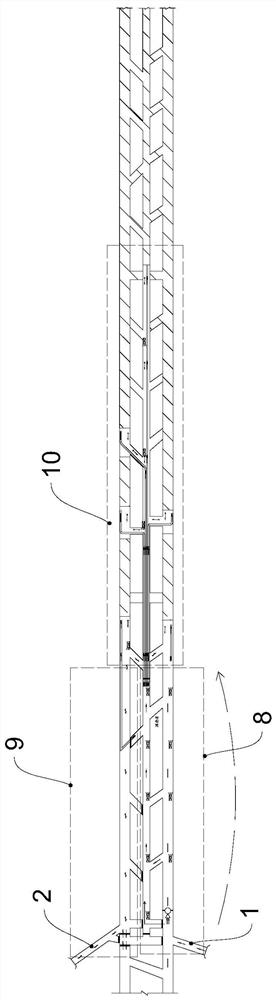

[0026] see figure 1 and figure 2 , the press-in construction ventilation system provided in this embodiment is especially suitable for the construction of extra-long high-gas tunnels. The press-in construction ventilation system drain tunnel 1, inclined shaft 2, left line 3, right line 4 and level guide 5, left line The line 3 and the right line 4 are located on both sides of the flat guide 5, the drainage tunnel 1 is located on the side of the right line 4 and communicated with the right line 4, and the inclined shaft 2 is located on the side of the left line 3 and communicated with the left line 3. A plurality of left crossways 6 are arranged between the left line 3 and the level guide 5, and the plurality of left crossways 6 are arranged along the construction direction. The left line 3 communicates with the level guide 5 through the left crossway 6; A plurality of right crossways 7 are arranged along the construction direction, and the right line 4 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com