Steam boiler capable of controlling heating power through intelligent water level communication

A heating power and communication control technology, which is applied in the field of steam generating equipment, can solve problems such as affecting heating efficiency, low intelligence of steam boilers, and dangers, and achieve the effects of strengthening heat transfer, improving heating efficiency, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

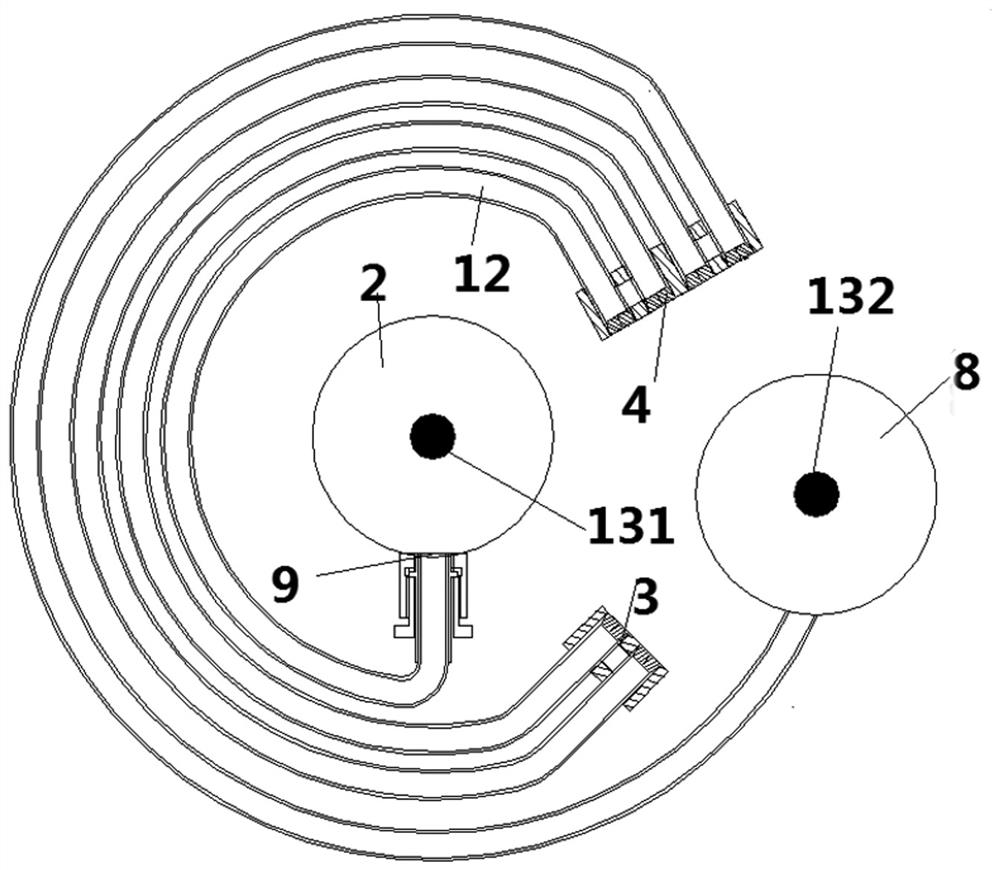

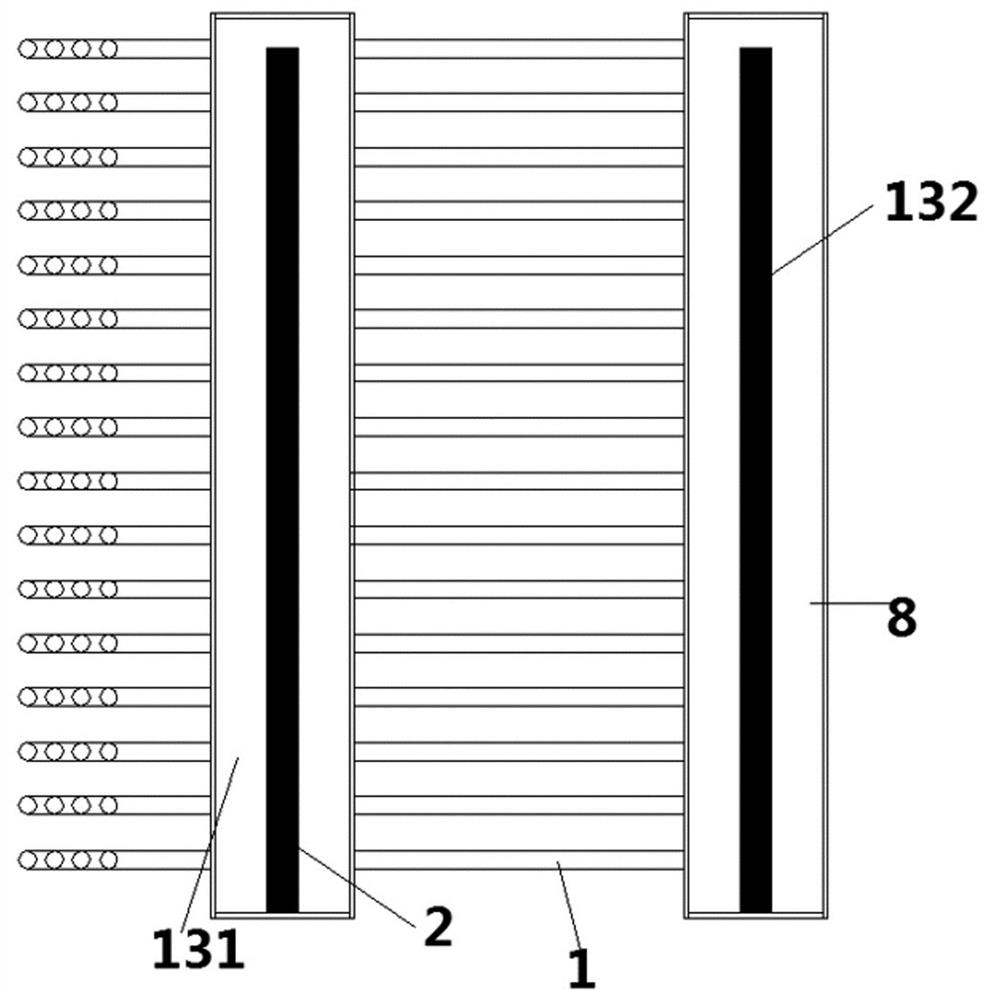

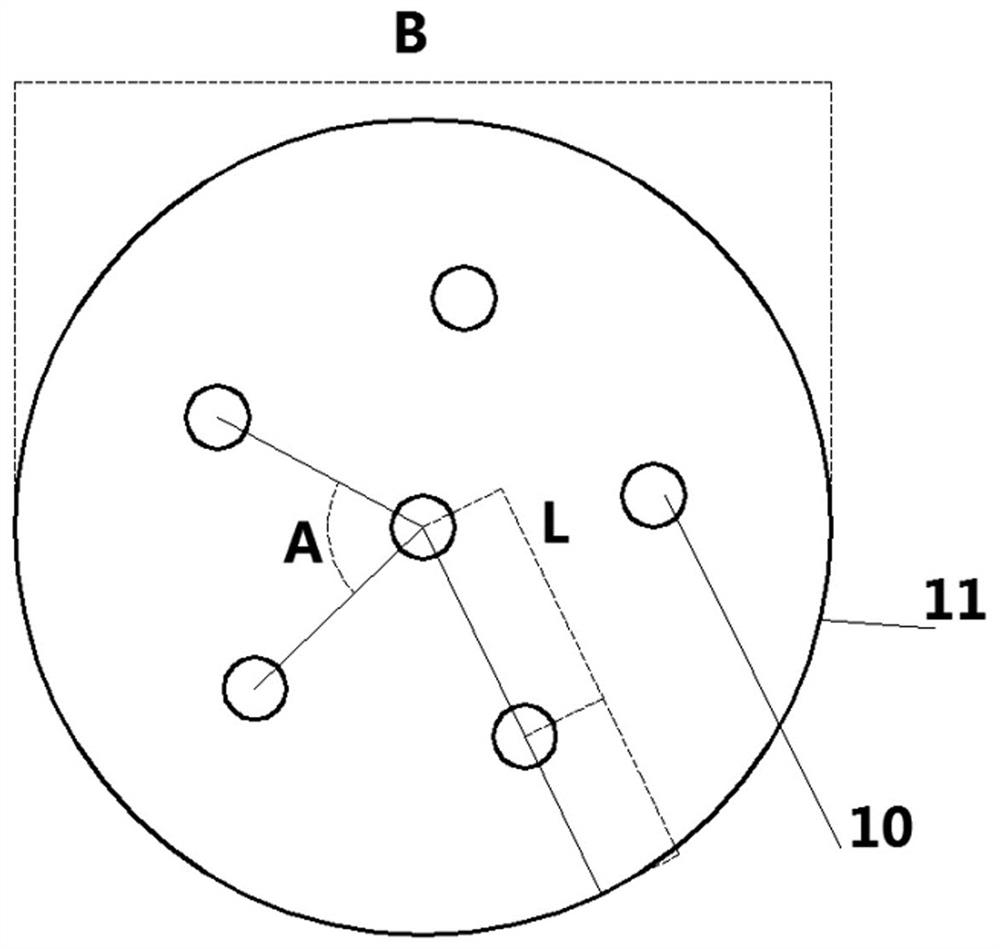

[0030] A boiler. The boiler includes an electric heating device 10 and a steam drum 11 . The electric heating device 10 is arranged in the steam drum 11 . The steam drum 11 includes a water inlet pipe 5 and a steam outlet 6 . The steam outlet 6 is arranged on the upper part of the steam drum.

[0031] Preferably, the steam drum is a cylindrical structure.

[0032] The water enters the steam drum 11 through a power device (preferably a water pump), and is heated in the steam drum 11 by an electric heating device 10 , and the generated steam is discharged through the pipeline of the steam outlet 6 .

[0033] Preferably, the exhausted steam, for example, enters a steam pipe, and objects to be dried, such as clothes, etc. are arranged on the steam pipe. Of course, steam can also enter the drying kiln, such as the steam pipe in the rotary kiln.

[0034] As preferably, the water inlet pipe 5 is connected to a running water pipe, and the water is replenished through the running wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap