Blasting hole pressure bearing test method

A technology of pressure test and blast hole, which is applied in the field of blasting experiments, can solve the problems of safety risks, explosion energy waste, ore loss, etc., and achieve the effect of simple and effective test circuit, large measurement range and long acquisition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

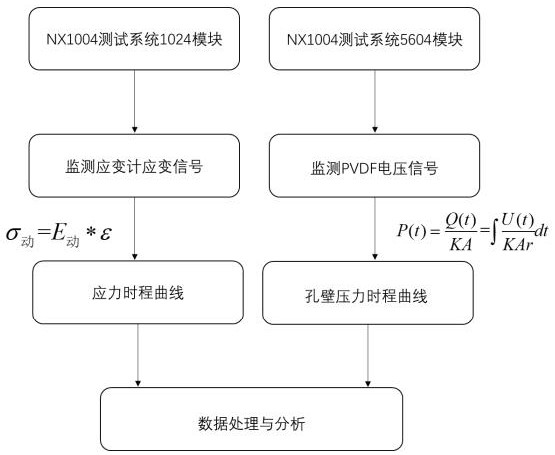

[0020] see Figure 1 to Figure 2 , the present invention provides a technical solution: a blasting hole pressure test method, characterized in that it includes the following steps:

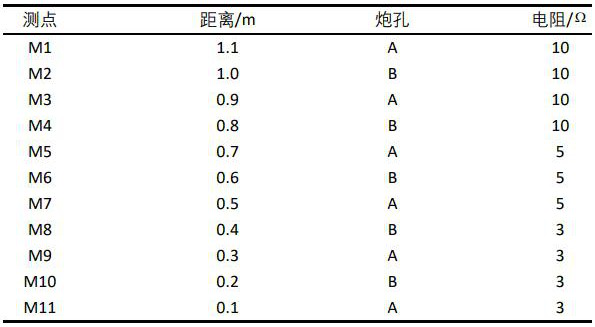

[0021] Step 1: Model construction. By pouring a concrete model with a similarity ratio of 1:1, the blasting process of the tunnel construction site is simulated. According to the PVDF pressure sensor pasted on the wall of the blast hole and the strain brick pre-embedded in the concrete model, Measure the peak pressure time history curve of the surrounding hole wall and the radial and tangential stress distribution at different measuring points in the medium around the blasthole. The full-scale concrete blasthole model belongs to the mass concrete model, which makes the measures for pouring and maintenance It is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com