Ball flow positioning and tracking experimental device and method

An experimental device, positioning and tracking technology, applied in the field of nuclear engineering, can solve the problems of heavy workload, high cost, and the success rate and accuracy of experiments need to be improved, and achieve the effect of rapid positioning and tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

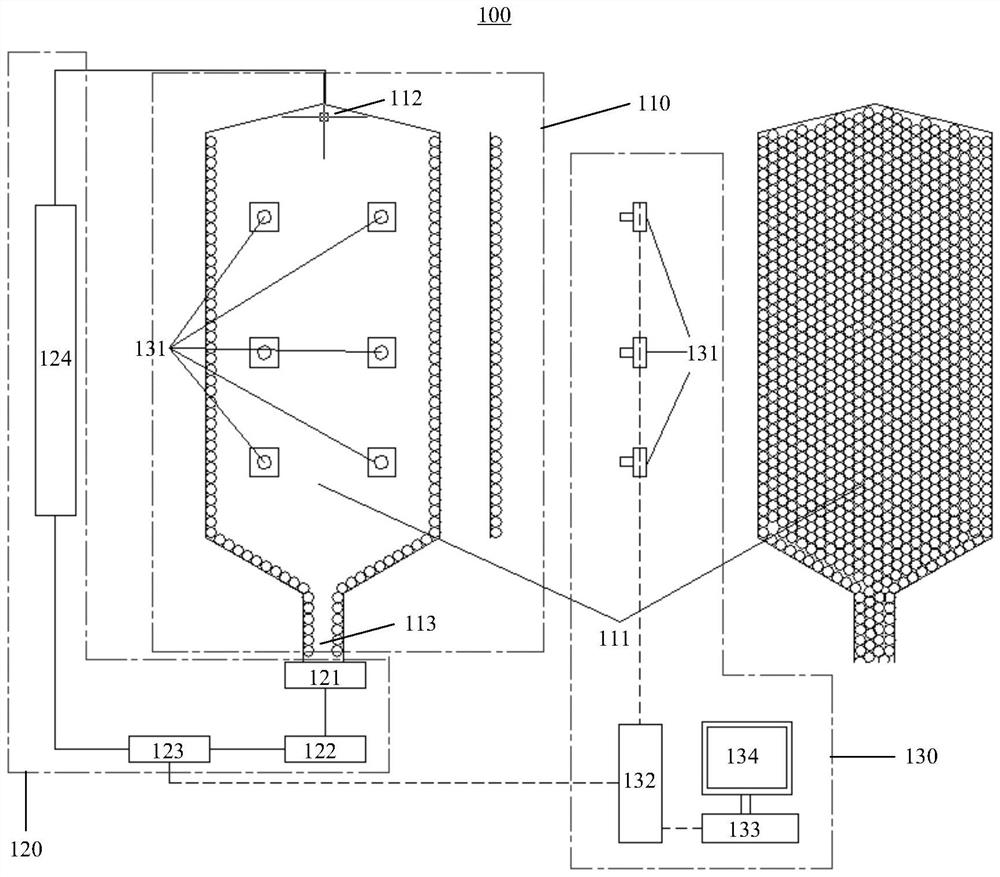

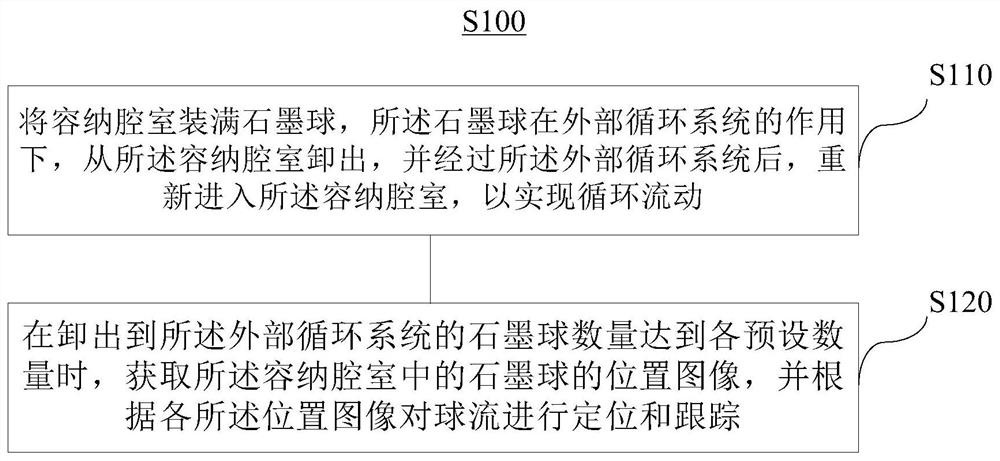

[0037] In one aspect of the present invention, as figure 1 As shown, an experimental device 100 for positioning and tracking a ball flow is provided. The experimental device 100 includes a two-dimensional core stand 110 , an external circulation system 120 and a computing system 130 . The two-dimensional core stand 110 is provided with an accommodating chamber 111 , so that several graphite spheres can be tiled in a single layer in the accommodating chamber 111 . The external circulation system 120 communicates with the containing chamber 111 , so that several graphite balls circulate in the containing chamber 111 . The computing system 130 is electrically connected with the external circulation system 120, so that when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com