Enameled wire

A technology of enameled wire and fixture, applied in the field of enameled wire, can solve the problems of easy deformation, deformation resistance and drop of insulating film, and achieve the effect of excellent deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

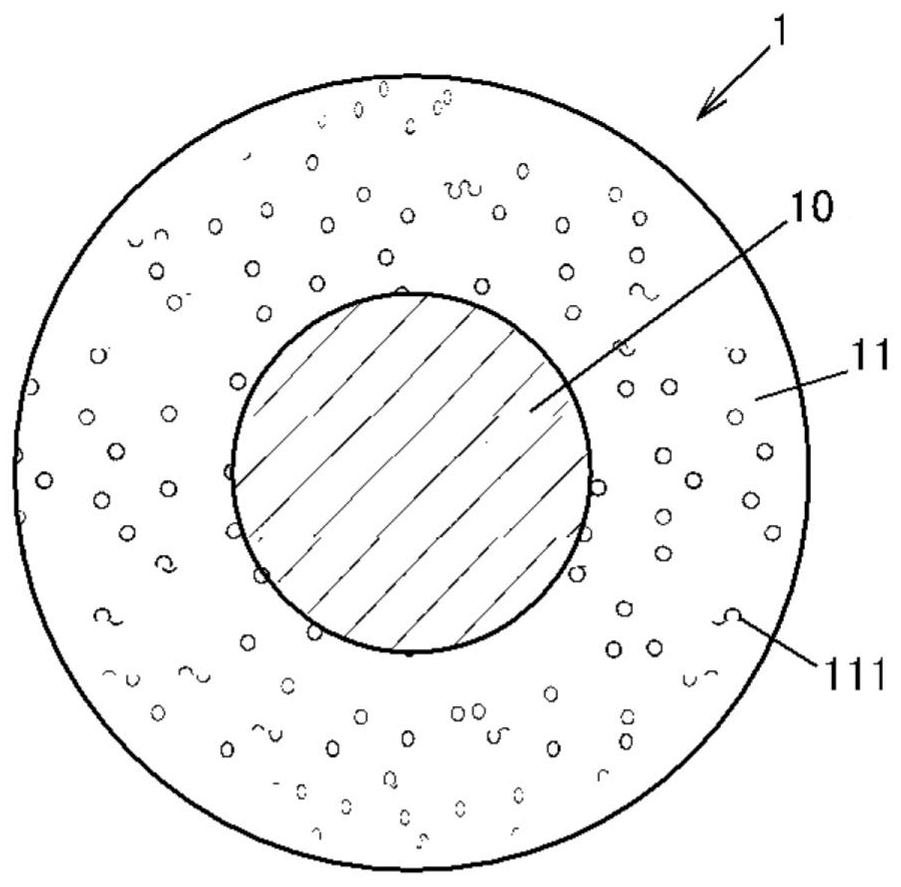

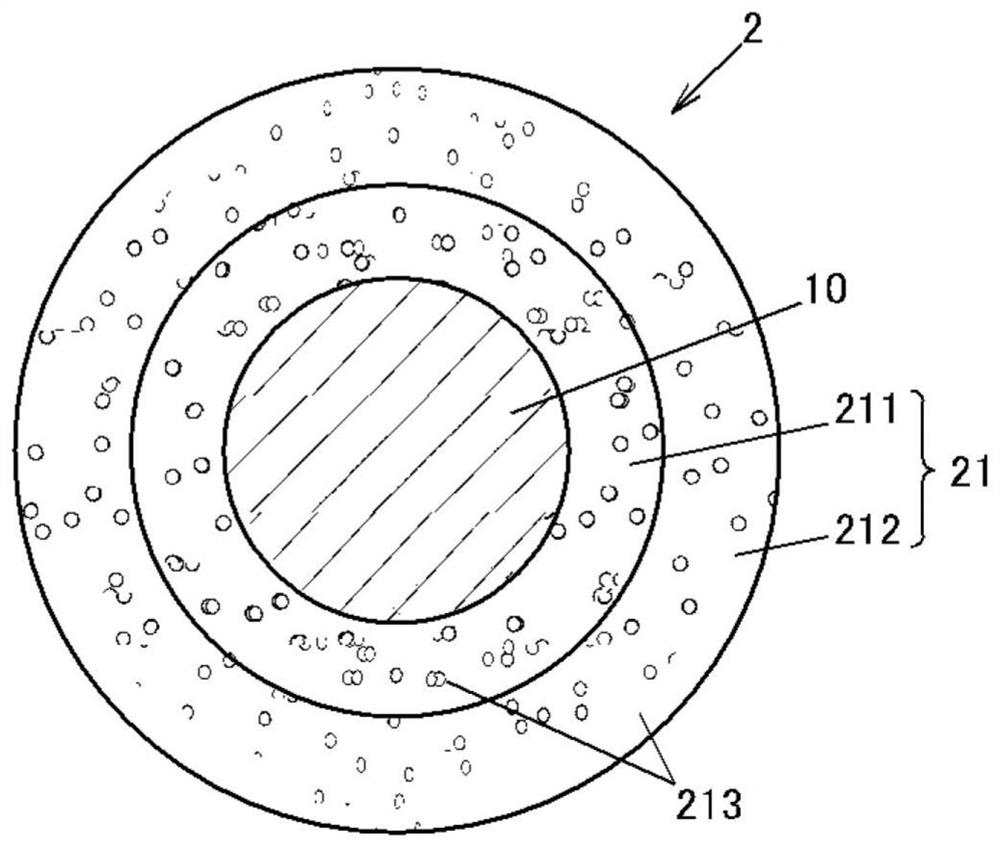

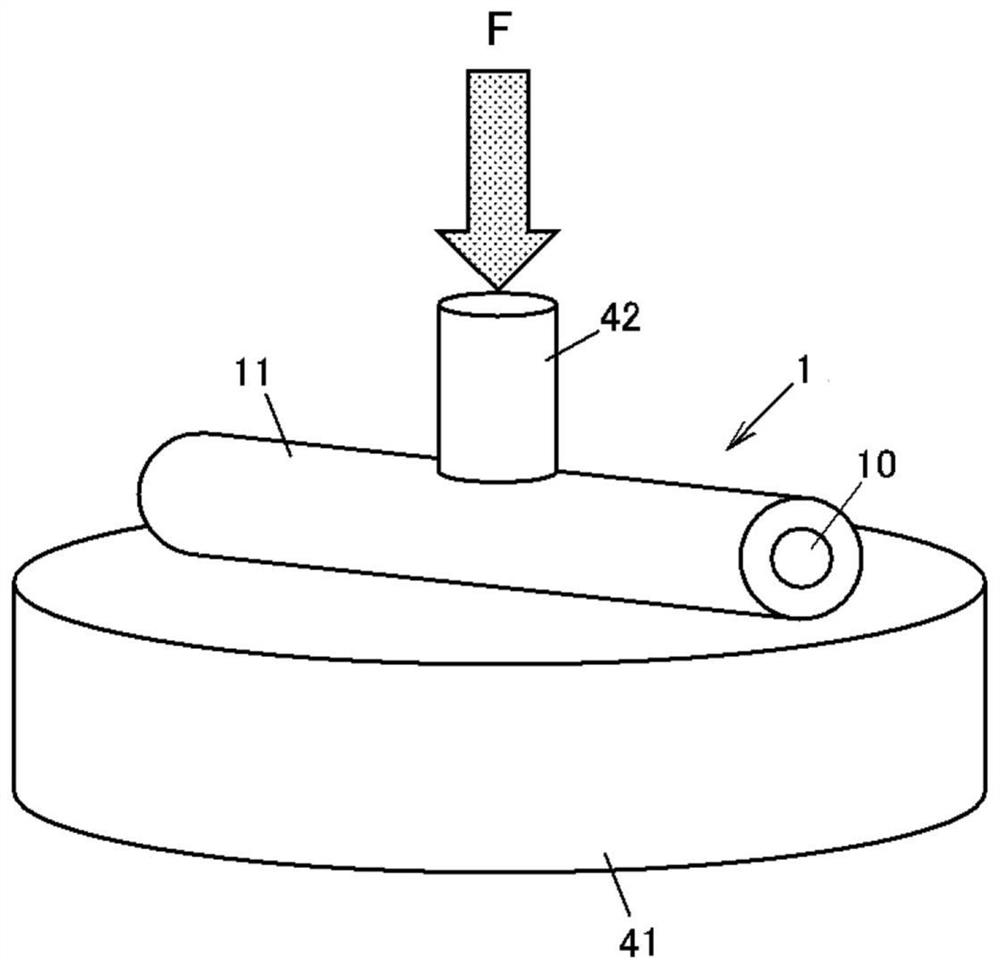

[0024] Fig. 1(a) is a sectional view perpendicular to the longitudinal direction of the enameled wire 1 according to the embodiment of the present invention. The enameled wire 1 includes a conductor 10 and an insulating film 11 provided around the conductor 10 and having a hole 111, and its deformation rate is less than 10%. In addition, the deformation|transformation rate is mentioned later.

[0025] The conductor 10 is a linear metal wire made of conductive material such as copper or copper alloy, aluminum or aluminum alloy, for example, a copper wire made of oxygen-free copper or low-oxygen copper. In addition, the structure of the conductor 10 is not limited to this, For example, the conductor 10 may use the wire which plated metal, such as nickel, on the outer periphery of a metal wire. The conductor 10 shown in FIG. 1( a ) and FIG. 1( b ) has a circular cross-sectional shape perpendicular to the longitudinal direction, but is not limited thereto, and may be, for example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap