Servo motor driving system

A drive system and servo motor technology, applied in the control system, AC motor control, control of multiple AC motors, etc., can solve the problems of low control precision, large driver size, interference, etc., achieve large wiring area, and reduce the overall size , the effect of less wiring distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

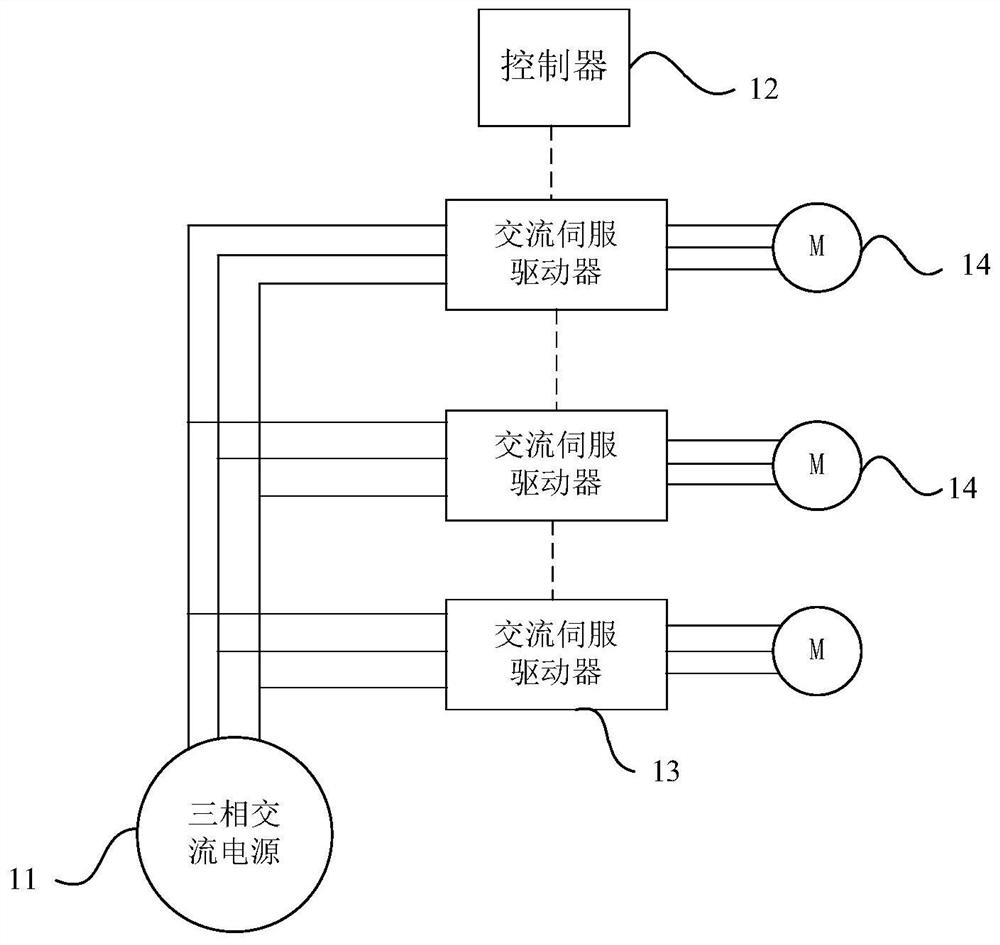

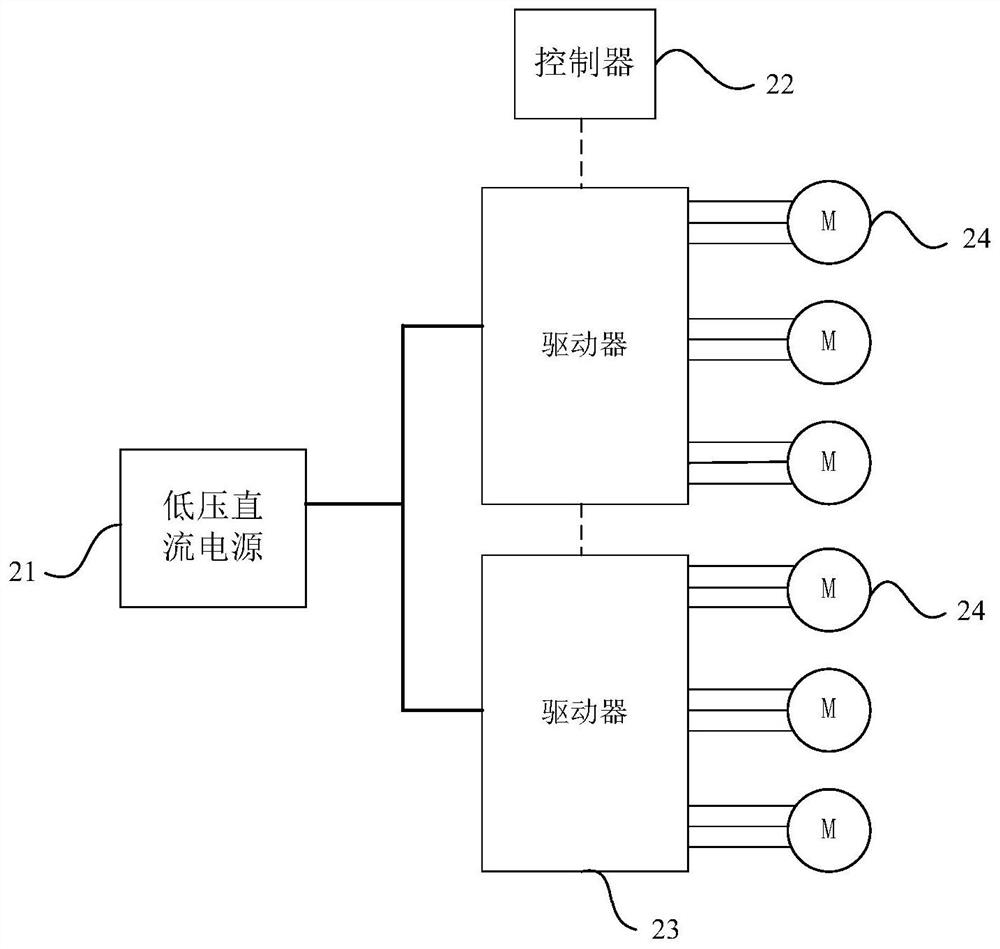

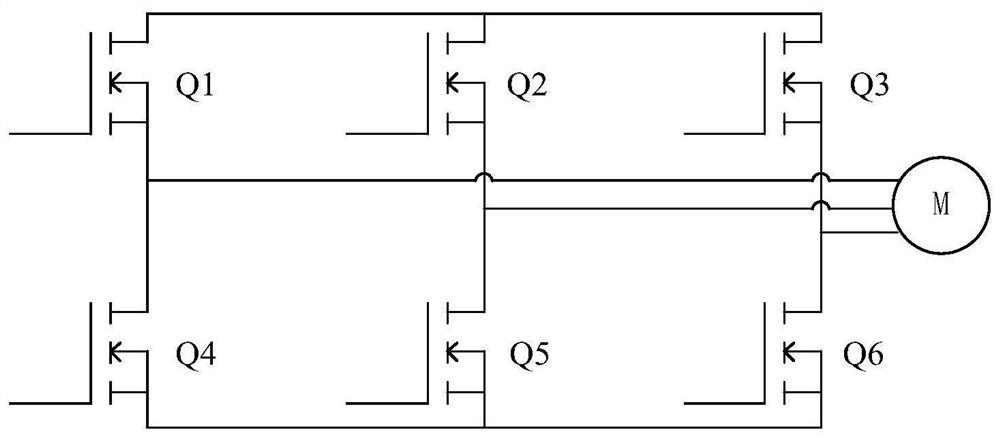

[0029] In the related art, the principle of the AC servo driver is to modulate the power devices used by three-phase SPWM inverters. Generally, IGBT tubes are used as the power devices, and AC power is used for powering them. see figure 1 , the AC servo driver 13 is connected with the three-phase AC power supply 11, and the voltage (AC 380V or AC 220V) output by the three-phase AC power supply 11 supplies power for the AC servo driver 13, so that the AC servo driver 13 is under the control of the upper computer controller 12 The drive motor 14 moves. Since the AC servo drive is powered by high-voltage AC, it will introduce strong and complex interference, and even affect the normal operation of the upper computer controller in severe cases. And because of the use of high-voltage AC power supply, it is required to have a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com