Half-feeding combine harvester threshing device and threshing method

A technology for combine harvesters and threshing devices, which is applied in the direction of harvesters, threshing equipment, cutters, etc., and can solve problems such as the need to improve the re-extraction effect of rolling action, easy jamming and damage, etc., so as to improve threshing work efficiency and facilitate maintenance , Increase the effect of threshing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

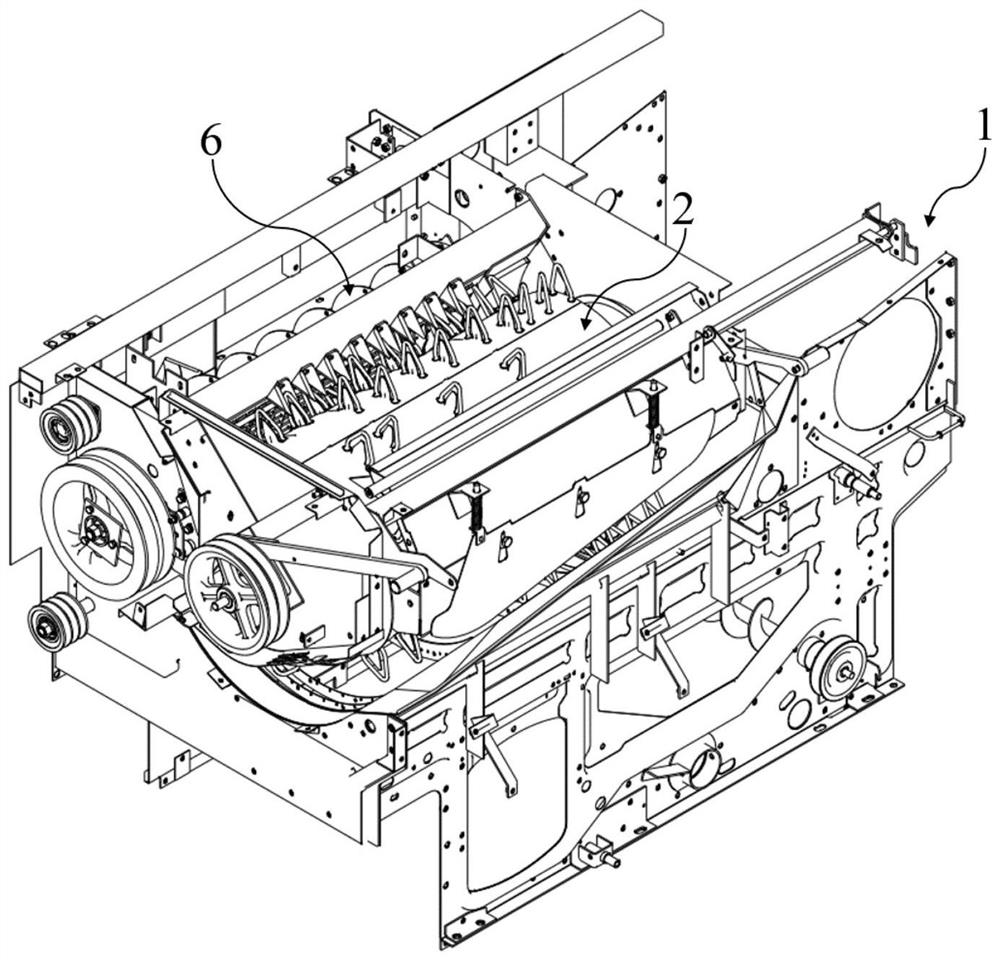

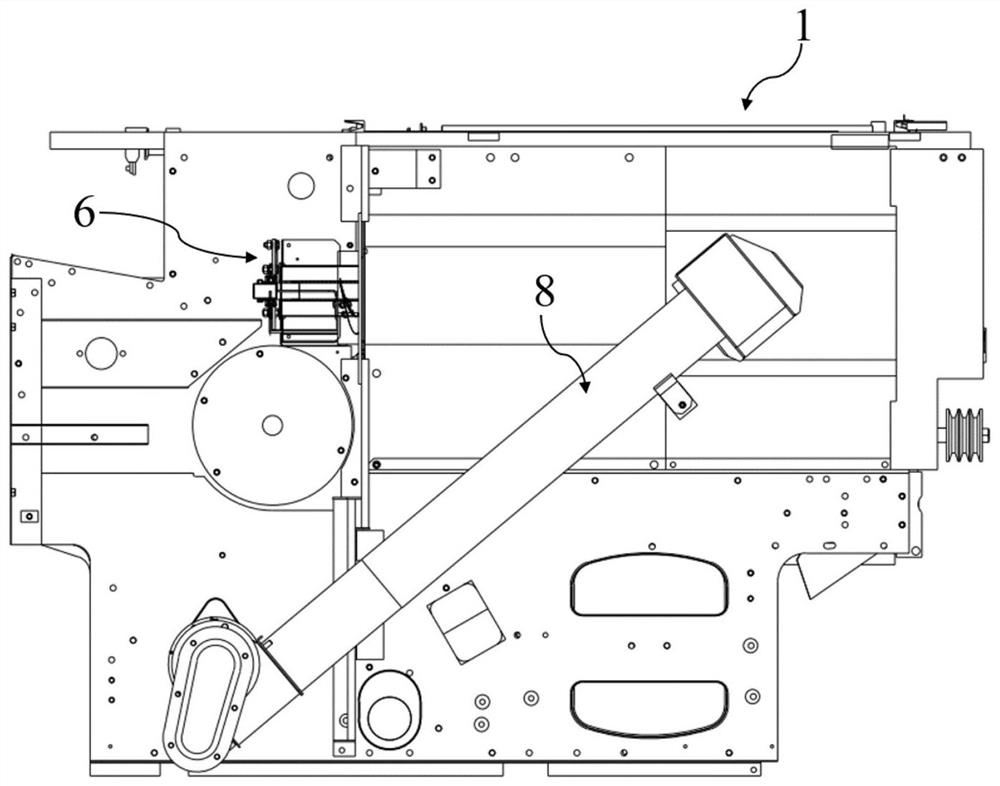

[0069] The half-feed combine harvester threshing device of the present embodiment comprises:

[0070] Rack 1;

[0071] The threshing drum part 2 is arranged horizontally in the frame 1;

[0072] The first sieve plate part 3 is horizontally arranged under the threshing drum part 2, and the first sieve plate part 3 cooperates with the threshing drum part 2 to sieve the grain in the rice material;

[0073] Cleaning room 4, which is arranged below the first sieve plate part 3, and the cleaning room 4 cleans the grains in the first sieve plate part 3 and sieves off the materials and discharges the miscellaneous materials from the bottom of the cleaning room 4;

[0074] The miscellaneous conveying auger 5, which is horizontally arranged under the cleaning chamber 4, transfers the miscellaneous materials discharged from the cleaning chamber 4 to the outside of the frame 1;

[0075] Also includes:

[0076] The re-extraction drum part 6 is horizontally arranged between the threshing...

Embodiment 2

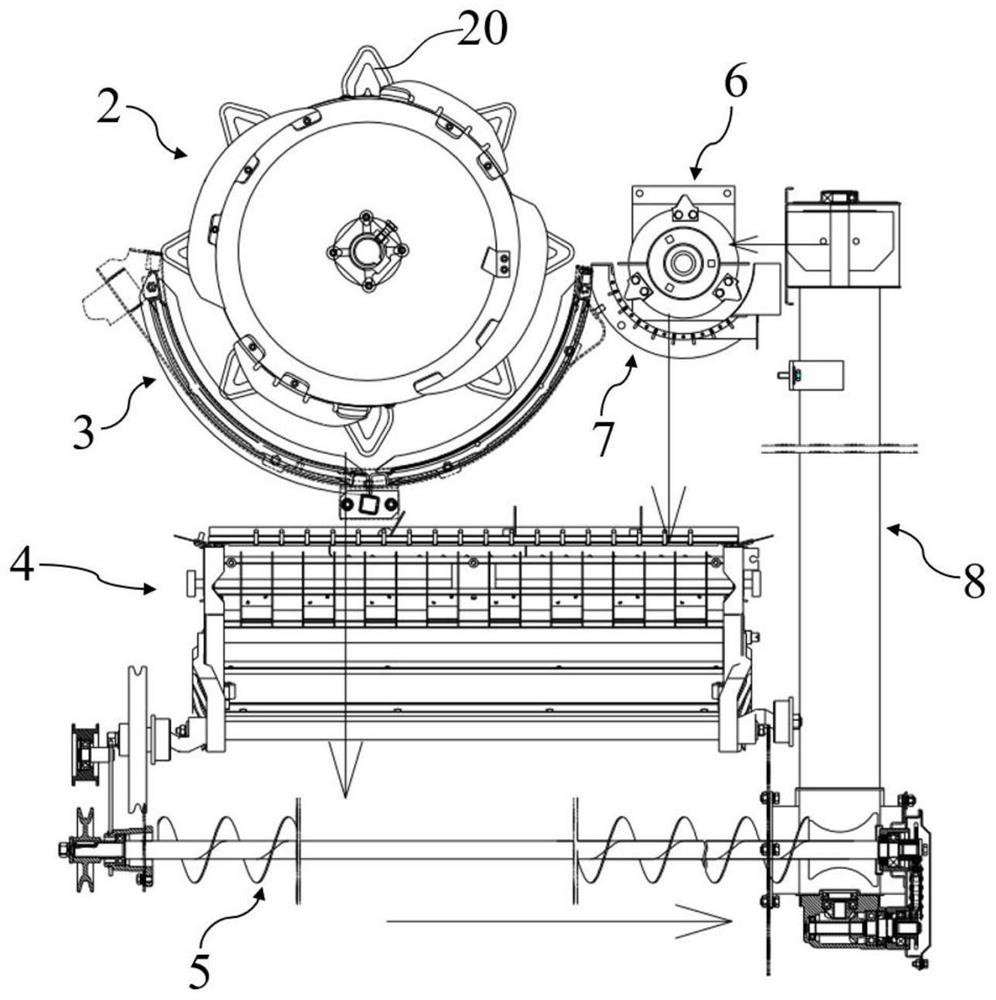

[0087] The semi-feed combine harvester threshing device of this embodiment is further improved on the basis of embodiment 1, the threshing drum part 2 is a bow-toothed drum, and the first sieve plate part 3 is a concave plate sieve.

[0088] Such as image 3 As shown, the bow-toothed drum, that is, a number of bowed teeth 20 are formed on the side wall of the drum, which can continuously brush and beat the rice material during rotation, thereby promoting the grain to come out, and the concave plate sieve can increase the amount of rice fed. The area where the material receives the action of combing and brushing can improve the efficiency of threshing.

Embodiment 3

[0090] The half-feed combine harvester threshing device of the present embodiment is further improved on the basis of embodiment 2, and the re-extraction drum part 6 includes:

[0091] Intermediate shaft 60, which is rotatably connected with frame 1;

[0092] A circular tube 61, which is sleeved and fixed on the outer wall of the intermediate shaft 60;

[0093] The auger blade 62 is fixed on the outer wall of the circular tube 61 in a spiral manner;

[0094] Cutter teeth 63, which have several, are all connected to the outer edge of the auger blade 62 and stretch out;

[0095] The axis of the intermediate shaft 60 is parallel to the axis of the threshing cylinder part 2 .

[0096] Such as Image 6 with Figure 7 As shown, the intermediate shaft 60 of the re-rolling drum part 6 of this embodiment is rotatably connected to the frame 1, one end of the intermediate shaft 60 is rotatably connected to the frame 1 through the bearing seat structure, and the other end is also rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com