Wet and dry dual-purpose dust collector capable of improving corner cleaning capacity

A cleaning ability, dry and wet dual-use technology, applied in the direction of vacuum cleaners, cleaning equipment, suction nozzles, etc., can solve the problems of difficult overall structure design and layout, increase the labor intensity of cleaning personnel, and reduce the willingness of cleaning personnel to use, etc., to achieve convenience Daily cleaning and maintenance, ingenious overall structure design, and good walking stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

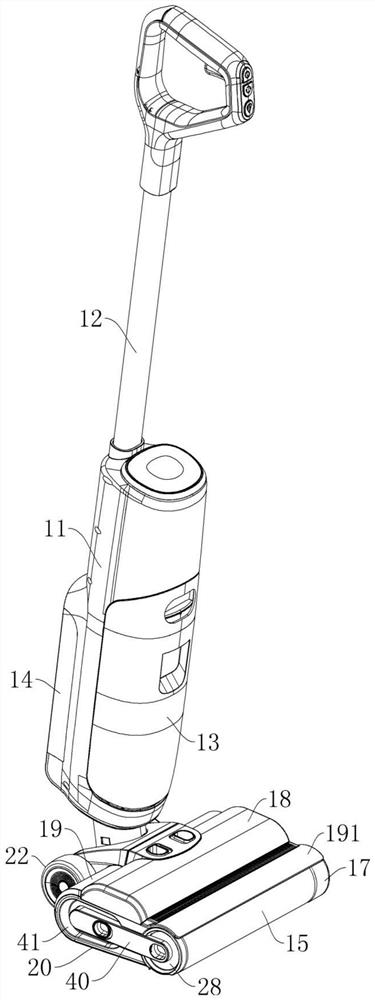

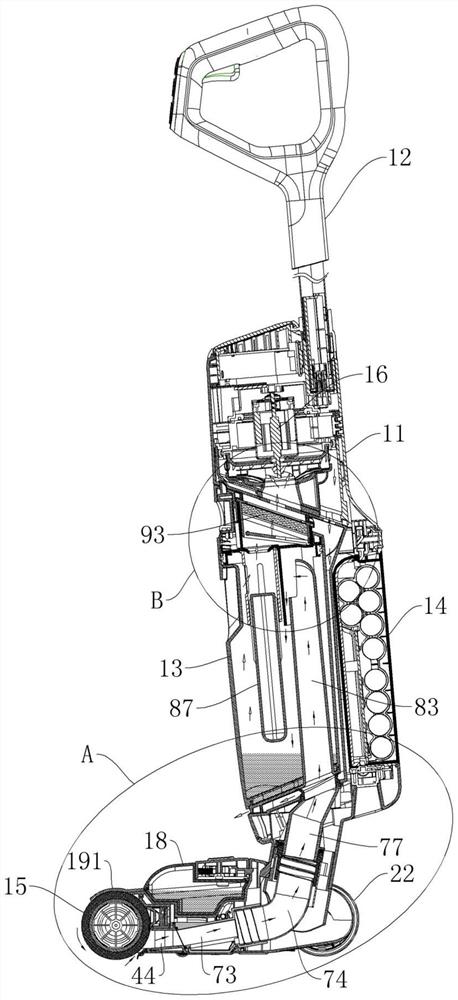

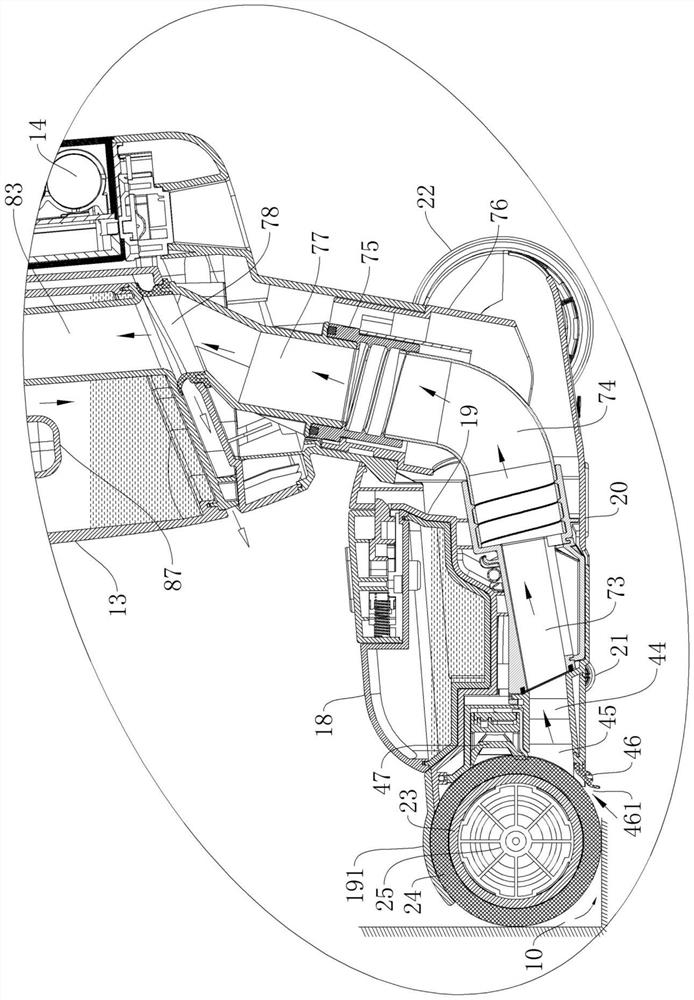

[0042] refer to Figure 1-Figure 18 As shown, the present invention is an embodiment of a wet and dry vacuum cleaner with increased corner cleaning ability;

[0043] refer to Figure 1-Figure 6 As shown, a wet and dry vacuum cleaner with increased corner cleaning ability includes: ground brush parts, the ground brush parts include a main housing, a clean water tank 18 and a rolling brush 15 that are all installed on the main housing; The rolling brush 15 is rotatably mounted on the front end of the main housing, and the driving mechanism 17 for driving the rolling brush 15 to rotate is installed on the main housing, and the main housing is provided with a motor corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com