Medium-temperature common oriented silicon steel and preparation method thereof

A common technology for oriented silicon steel, which is applied in the field of medium-temperature ordinary oriented silicon steel and its preparation, can solve problems such as edge cracks, cracks, and broken bands, and achieve the effects of reducing edge cracks, reducing hardness, and improving atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

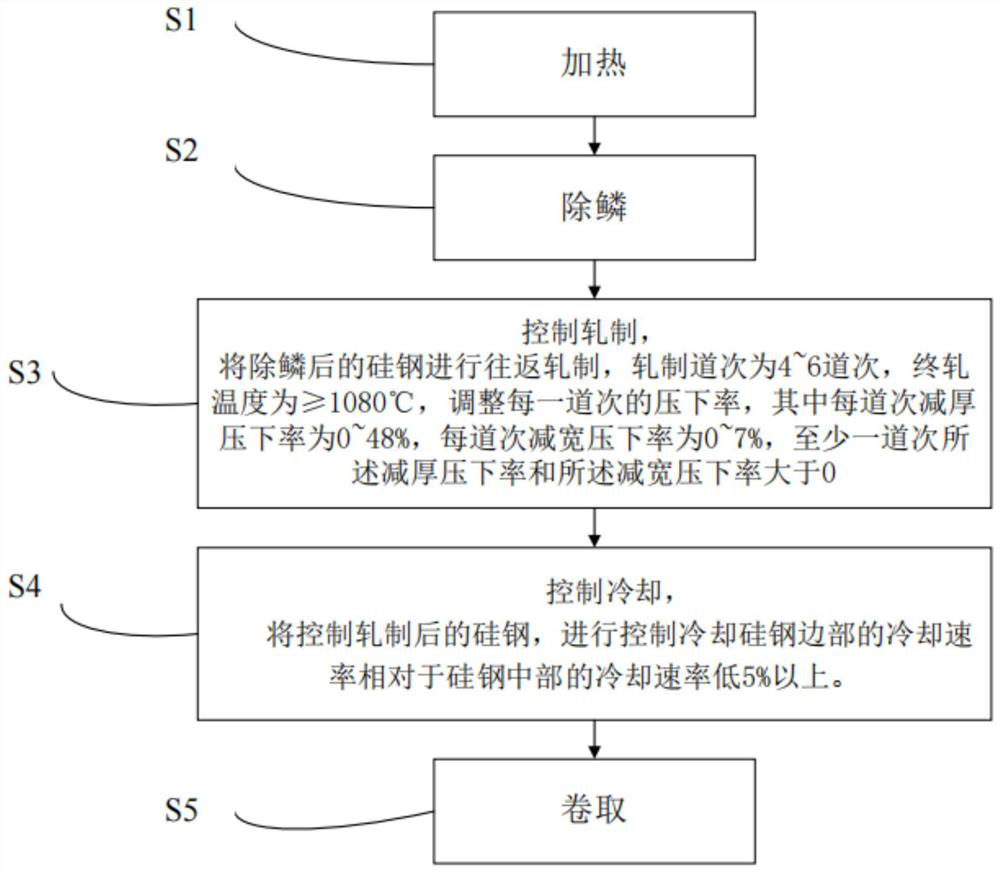

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, not to limit the present application.

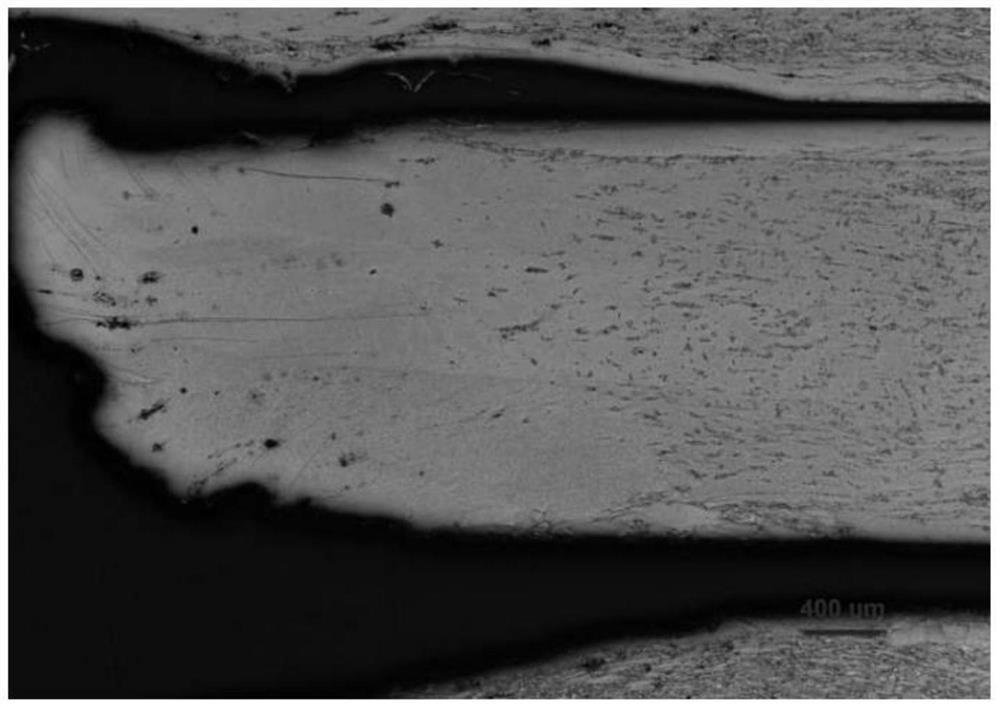

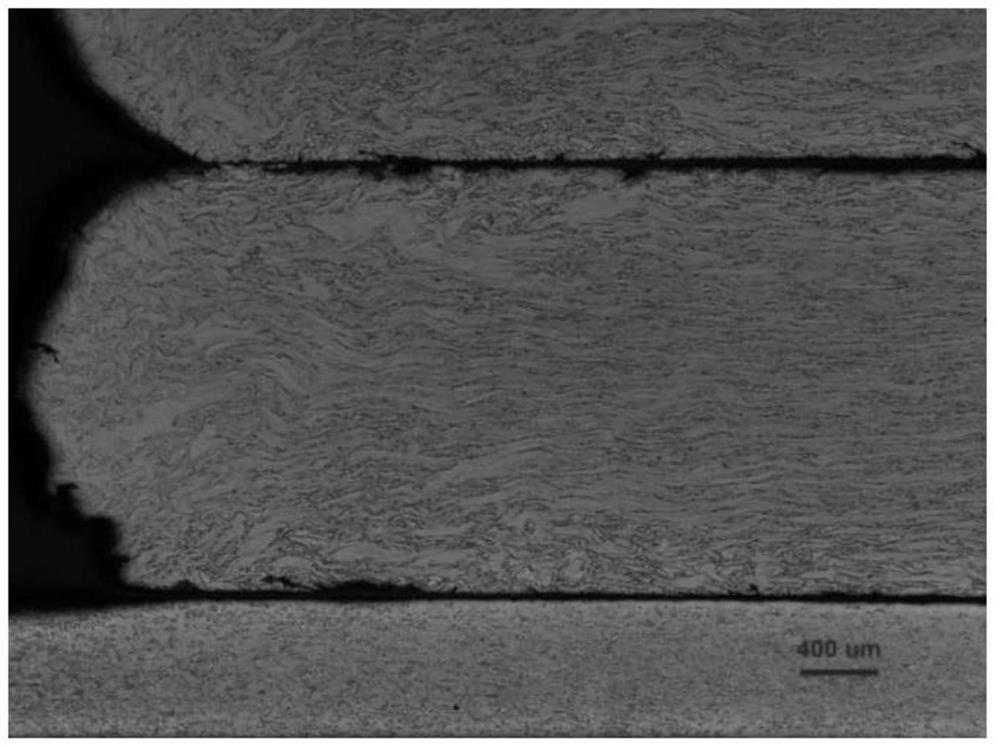

[0035] The applicant noticed that the existing medium-temperature ordinary grain-oriented silicon steel is prone to micro-cracks, small cracks, and even serious edge cracks after cold-rolling process, which eventually leads to large fissions and even broken belt accidents. Through further research, the applicant found that due to the high silicon content, coarse grains and high brittleness of ordinary grain-oriented silicon steel at medium temperature, the grains tend to grow excessively during the heating process, and the corners of the slab are more likely to be decarburized. Therefore, the silicon steel The qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com