Full-automatic food filling production line

A production line, fully automatic technology, applied to the types of packaging items, packaging, transportation packaging, etc., can solve the problems of difficult control of sanitary conditions, affecting food safety, high labor costs, etc., to facilitate product promotion, meet market demand, reduce artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention are clearly and completely described below.

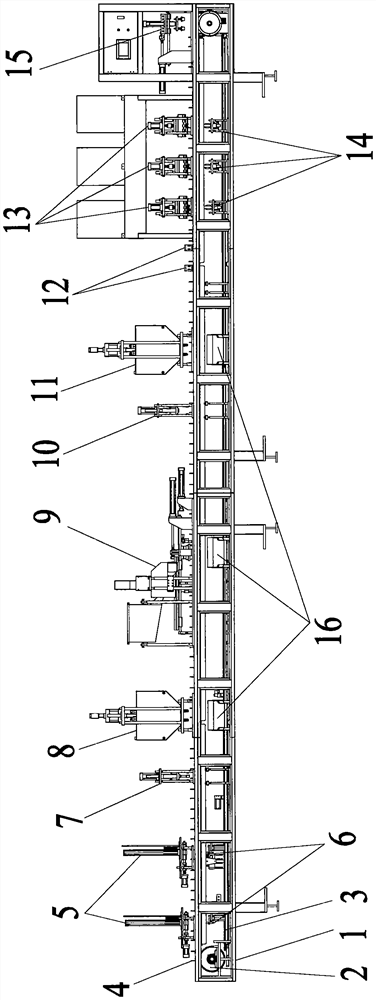

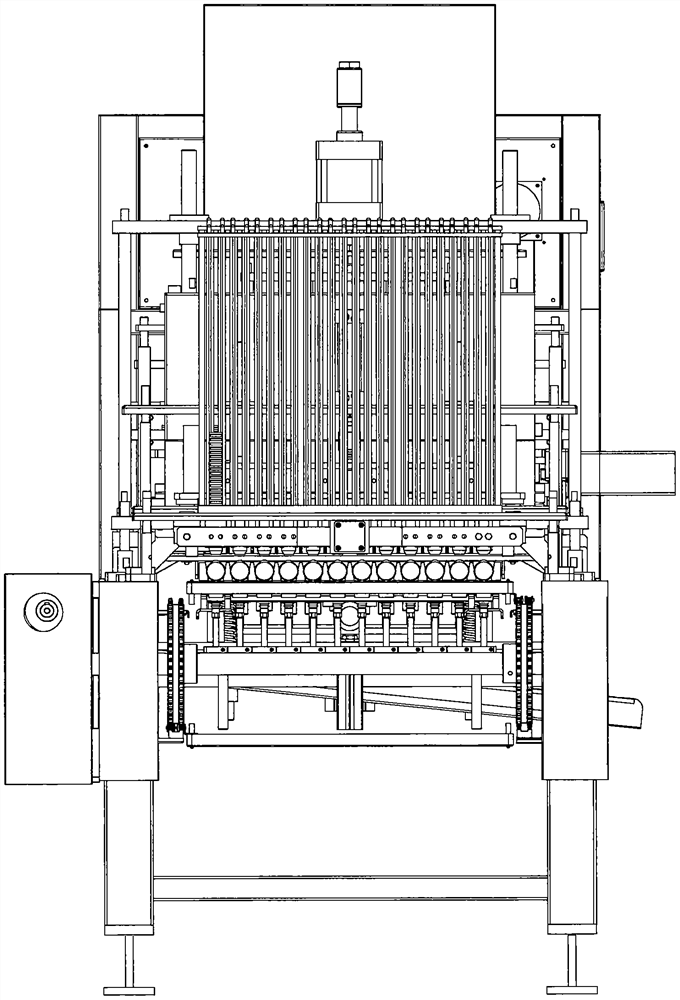

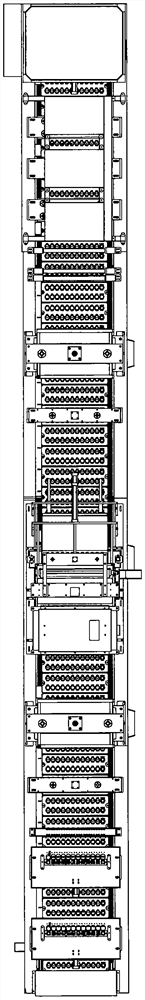

[0031] The specific structure is as Figure 1-3As shown, the fully automatic filling food production line mainly includes a frame body 1, a sprocket 2, a chain 3, a template 4, a cup holder 5, a lower cup mechanism 6, a cup pressing mechanism 7, a first filling mechanism 8, a lower Grain mechanism 9, granulation mechanism 10, second filling mechanism 11, lid closing mechanism 12, sealing mechanism 13, cup discharge mechanism 15, the two ends of the frame body 1 are respectively connected to the sprocket 2, and the sprocket 2 is close to the two ends respectively The chains 3 are synchronously linked, and two chains 3 are arranged side by side synchronously. A plurality of evenly arranged templates 4 are fixed on the two chains 3. The templates 4 are used for embedding cups, and a sprocket 2 is synchronously connected to the output end of the stepping motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com